Filter stick/cigarette online sampling mechanism and filter stick/cigarette sampling sending device

A technology for filter sticks and cigarette sticks, which is applied in the field of filter stick/cigarette stick sampling and testing, and can solve the problem that the quality of filter stick/cigarette stick products cannot be effectively guaranteed, cannot meet various automated production lines, and cannot detect filter stick/cigarette stick quality and other issues to achieve the effect of ensuring the reliability of sampling, simple structure and ensuring the reliability of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

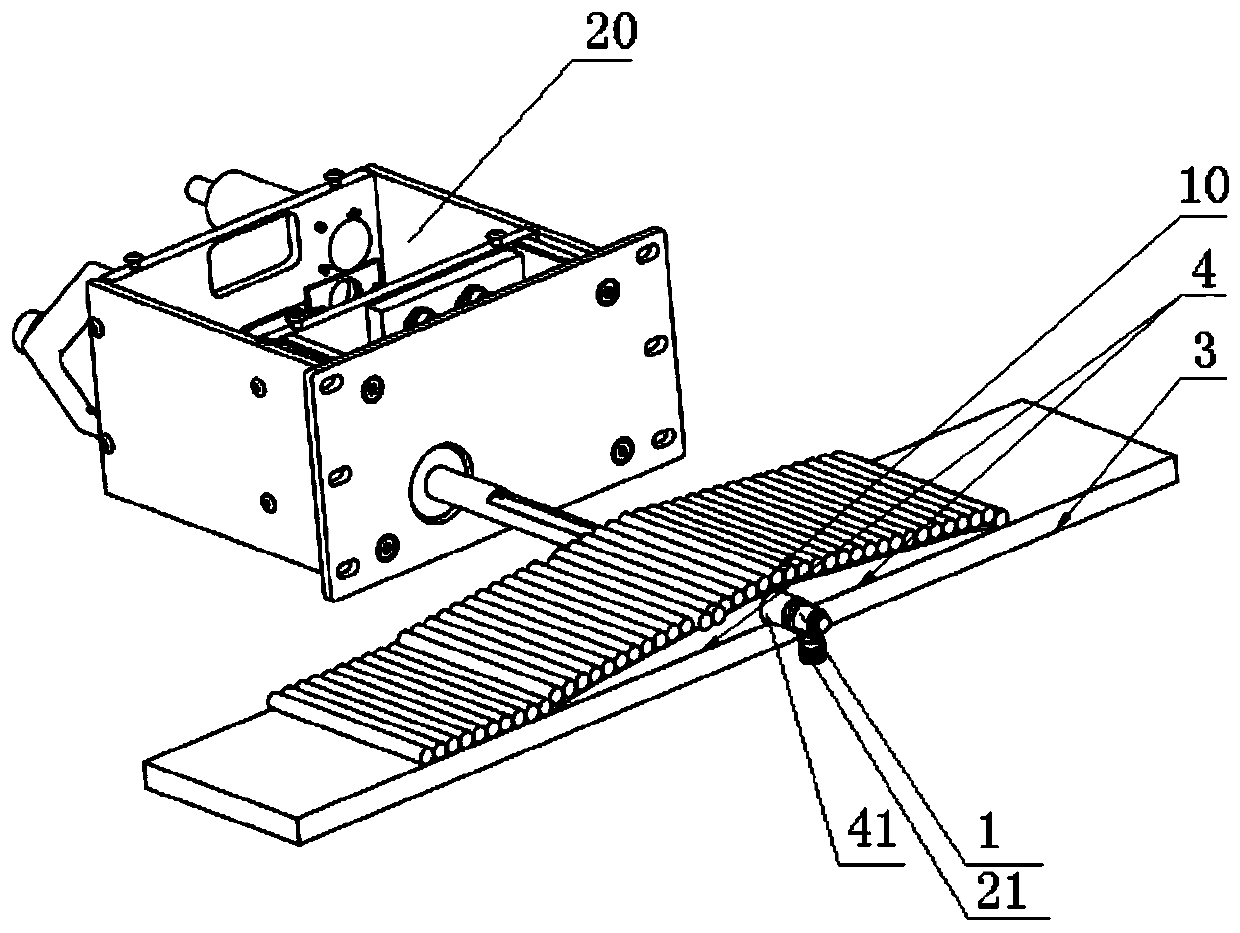

[0036] The filter rod / cigarette branch online sampling mechanism in this embodiment includes a sampling mechanism and a sampling auxiliary mechanism.

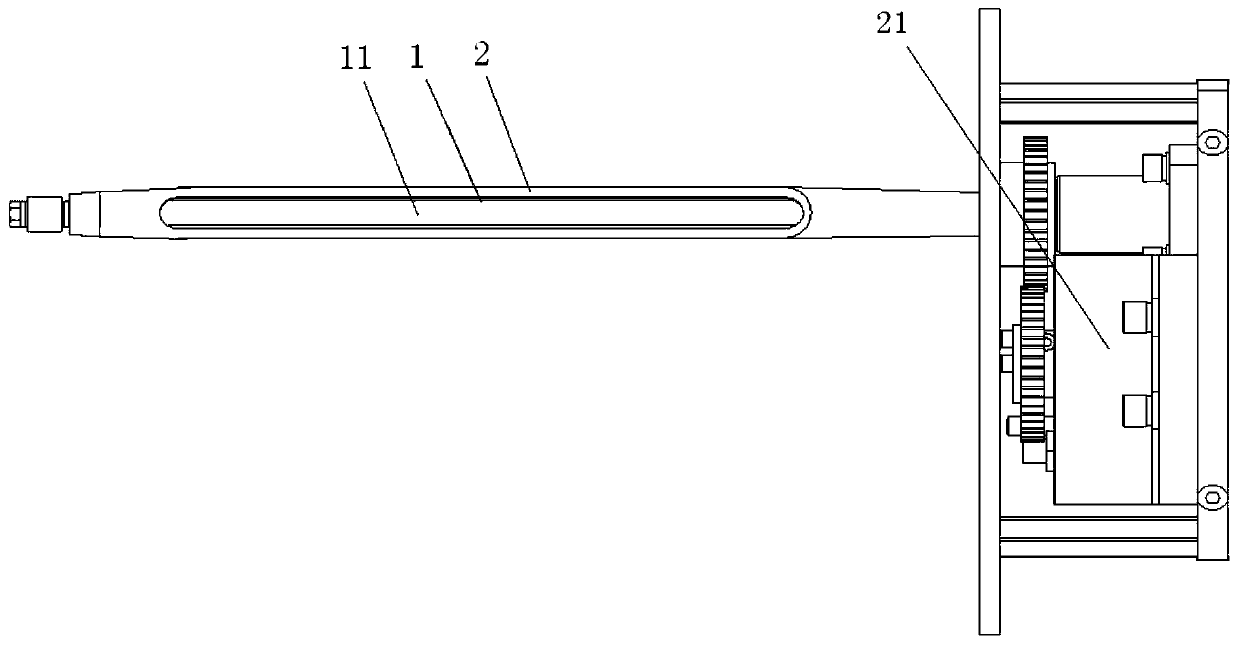

[0037] Refer to attached figure 1 As shown, the sampling mechanism includes a sampling tube 1 with a filter rod / cigarette inlet 11 at the upper end, and a rotating member 2 arranged on the outer periphery of the sampling tube 1 and capable of controlling the opening and closing of the filter rod / cigarette inlet 11 . In this way, when sampling is required, the rotary part 2 controls its rotation through the control part, so that it opens the filter rod / cigarette inlet 11 of the sampling tube 1, and after the filter rod / cigarette branch falls into the sampling tube 1, the rotary part 2 is then placed in the sampling tube 1. Rotate under the control of the control part to realize the closing of the filter rod / cigarette inlet 11.

[0038] Of course, the rotating member 2 can also be arranged inside the sampling tube 1, which can a...

Embodiment 2

[0043] The difference between this embodiment and the above-mentioned first embodiment is that the filter stick / cigarette branch online sampling mechanism of this embodiment is suitable for a production line where sampling is performed by a robot.

[0044] Refer to attached Figures 5 to 8 As shown, in this embodiment, the sampling auxiliary mechanism adopts a guide groove arranged above the filter rod / cigarette inlet 11 . The guide groove is composed of two oppositely arranged guide plates 5, and the two guide plates 5 are fixed on the outer periphery of the sampling tube 1 by fixing rings 6 at both ends thereof. In this way, after the manipulator sampling mechanism 7 takes the sample and rises to a suitable position, the sampling tube 1 of the sampling mechanism can be moved to the bottom of the manipulator grabbing unit 71 under the control of the transmission mechanism, and the filter rod / cigarette inlet 11 is opened. , to receive the drop of the filter rod / cigarette 10, ...

Embodiment 3

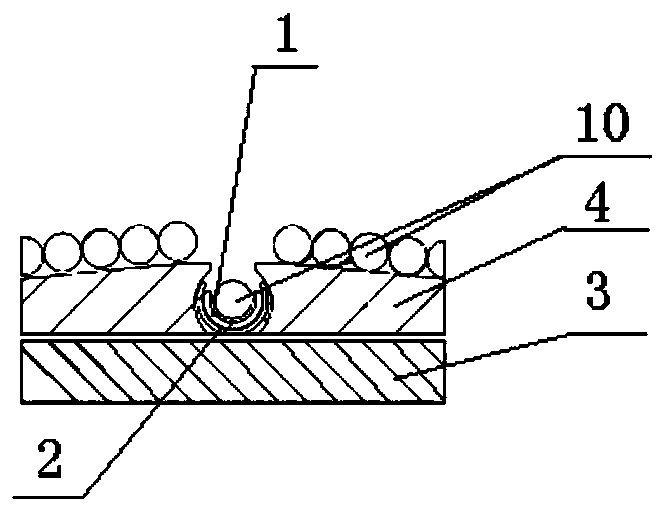

[0048] The difference between this embodiment and the above-mentioned second embodiment is that the filter rod / cigarette branch online sampling mechanism in this embodiment is suitable for a production line in which filter rods / cigarette branches are conveyed by rollers.

[0049] Refer to attached Figures 9 to 11 As shown, in this embodiment, on the basis of the second embodiment above, the sampling auxiliary mechanism also includes an arc-shaped funnel 9 arranged below the filter rod / cigarette stick conveying roller 8, and the upper part of the arc-shaped funnel 9 is U-shaped. Type, the lower part is a groove type slightly larger than the diameter of the filter rod / cigarette, and the bottom end of the arc-shaped funnel 9 is opposite to and connected to the upper end opening of the above-mentioned guide groove.

[0050] In this way, when the roller 8 rotates to the sampling position, the air hole on the corresponding position of the roller 8 passes through the air supply, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com