Cylinder driving system of cotton spinning comber

A drive system, technology of cotton spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

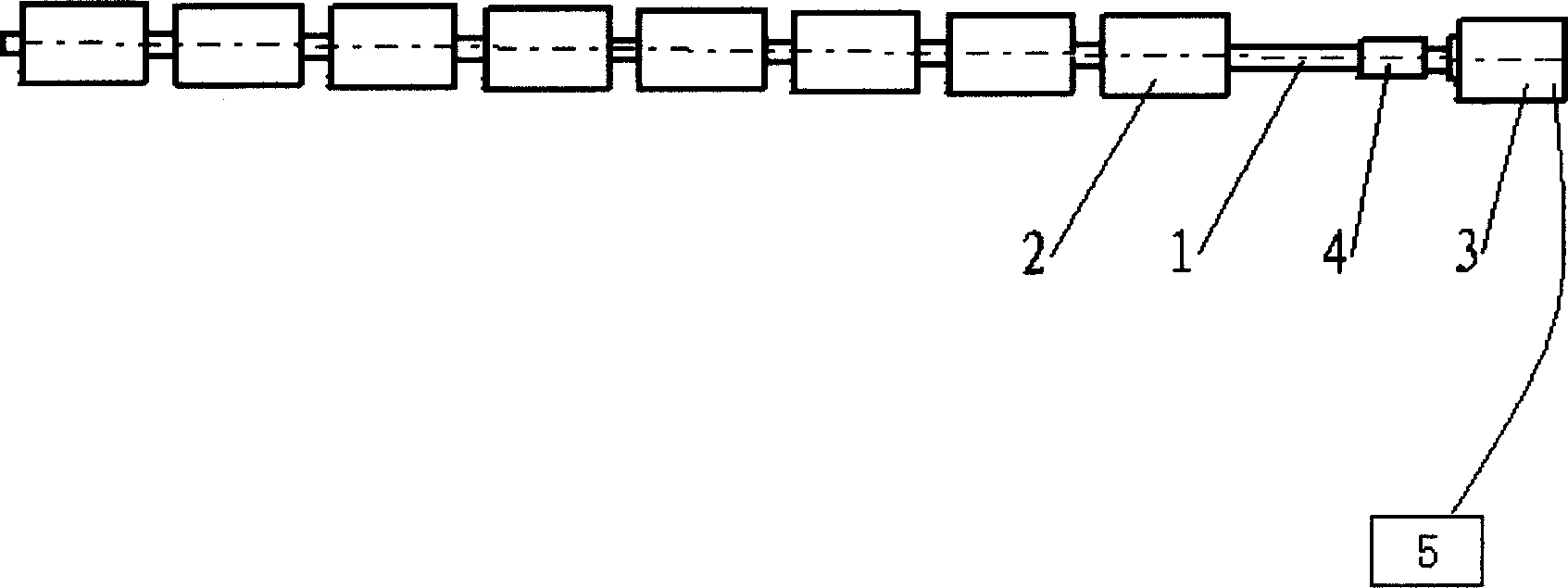

[0008] The cylinder driving system of the cotton spinning combing machine as shown in the figure is an improvement to the existing cylinder driving device of the cotton spinning combing machine with the same function. The specific improvement plan is: fix the cylinder 2 On the cylinder shaft 1 in the car, the cylinder shaft 1 in the car is directly connected with a dedicated motor 3 and driven separately, and the motor 3 is connected with a controller that issues manipulation instructions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com