Grab Dredger and Grab Hoisting Mechanism

A lifting mechanism and grabbing machine technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of large installation space, occupation, difficulty in achieving large span and Torque and other issues to achieve the effect of reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to specific embodiments and drawings, but the protection scope of the present invention should not be limited by this.

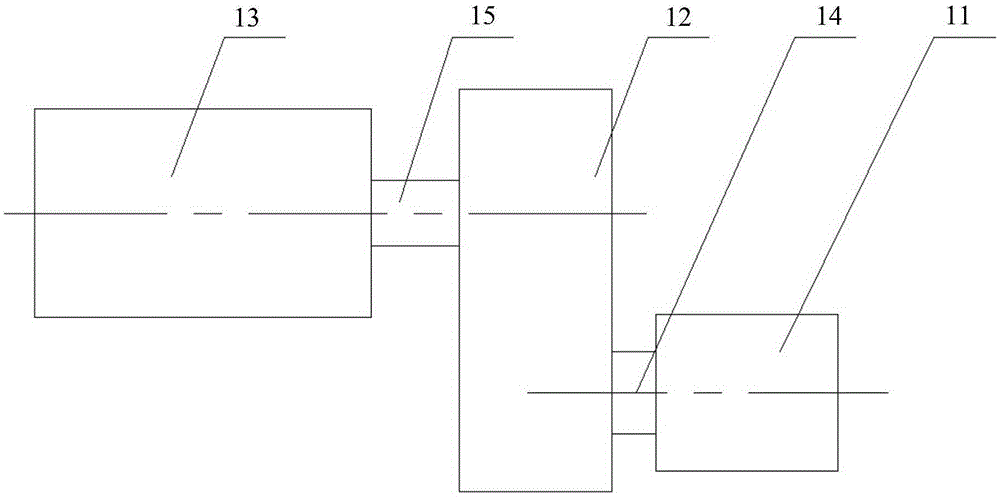

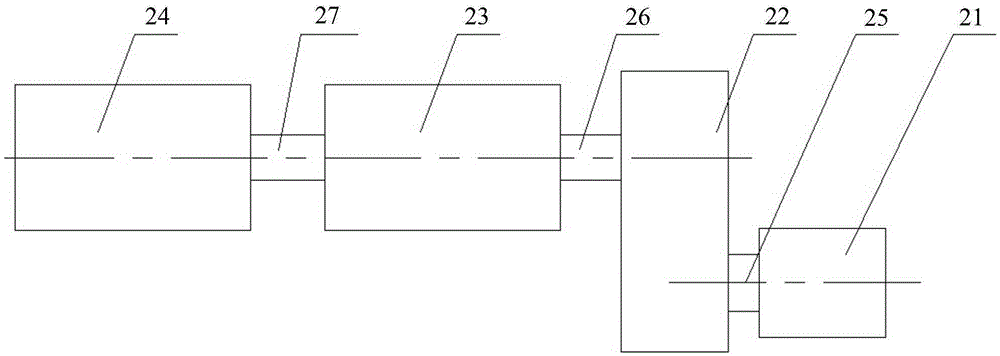

[0028] The lifting mechanism of the grab machine in this embodiment may include one or more groups of driving units. As a preferred embodiment, the number of the driving units may be 4 groups, but is not limited to this.

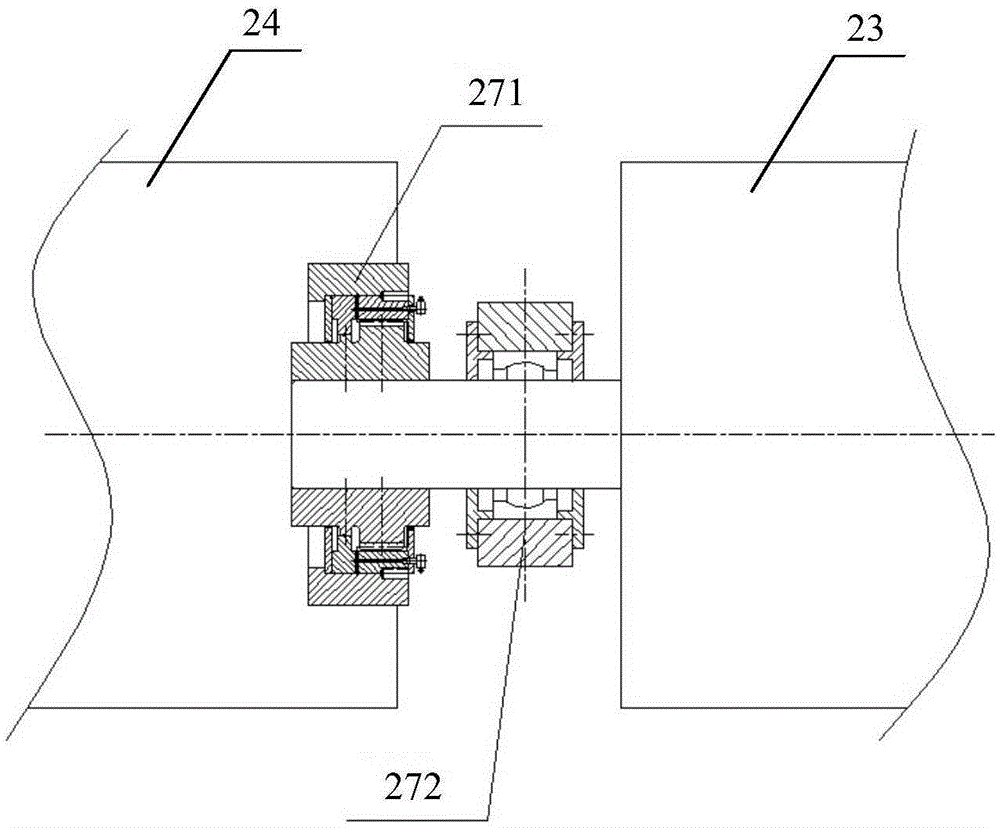

[0029] reference figure 2 , figure 2 The structure of a set of driving units is shown, and the driving unit includes: a motor 21, a transmission 22, a first reel 23, and a second reel 24. The motor 21 can be various conventional motors, such as a DC motor, an AC motor, etc.; the first reel 23 and the second reel 24 can be various conventional reels; the transmission 22 can be various suitable transmissions, which can be Provide one or more transmission ratios for selection.

[0030] Among them, the drive shaft of the motor 21 is connected to the input end of the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com