Sampling drilling tool with coring tube of multi-rod deep sampler

A core tube and sampler technology, which is applied in the field of space resource detection, can solve the problems of high cost of sampling volume, increase of drilling tool center volume, and high position accuracy requirements, so as to achieve high space utilization and reduce return weight , The effect of low precision requirements for the docking position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

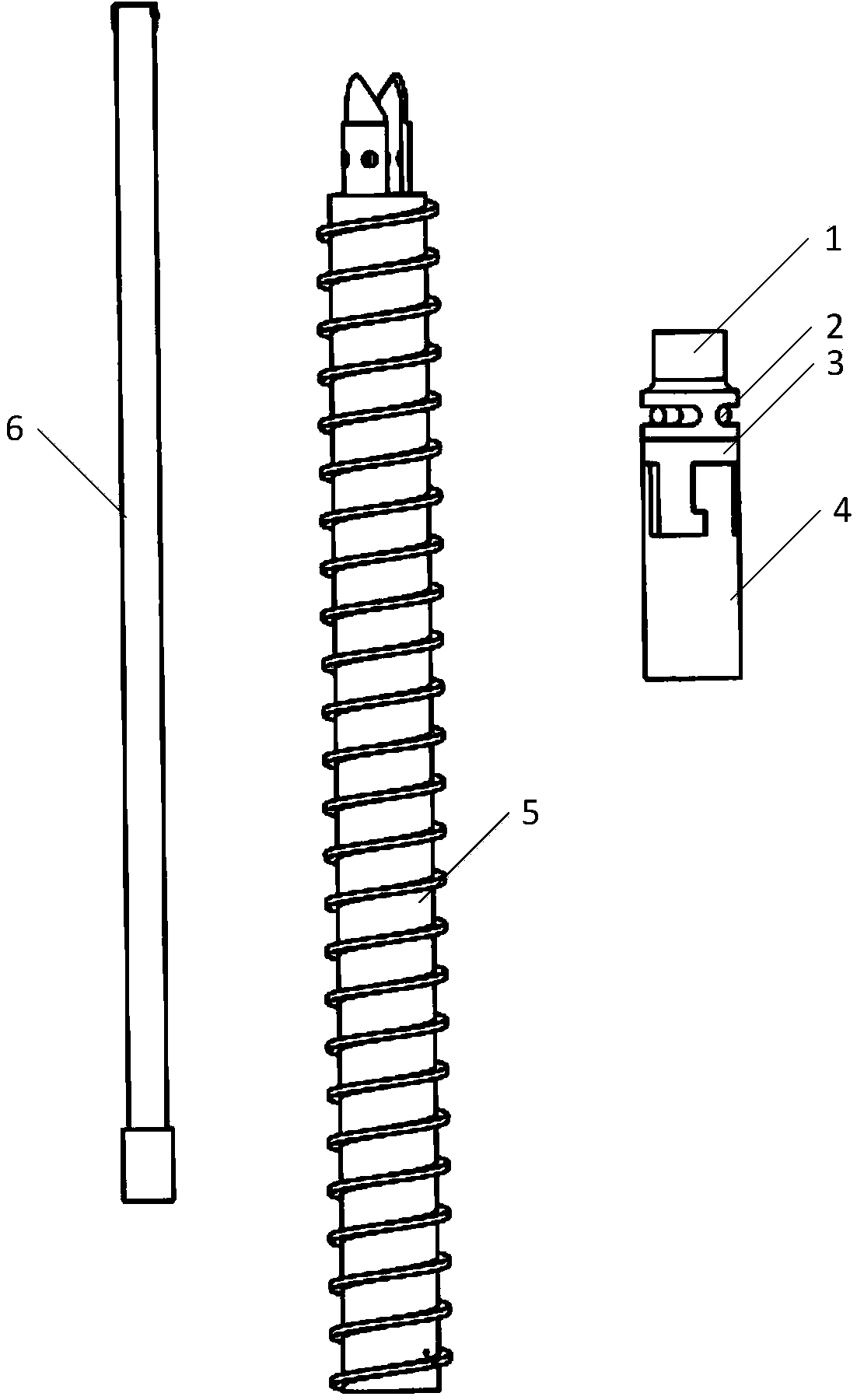

[0039] A kind of multi-rod deep sampler sampling drilling tool with coring tube of the present invention, as figure 1 As shown, it includes three parts: the drill pipe assembly, the core pipe 6 and the butt joint assembly of the drilling tool. Among them, multiple coring tubes and drill pipes can be selected for docking according to sampling requirements, and the number of core tubes can be more than the number of drill pipes.

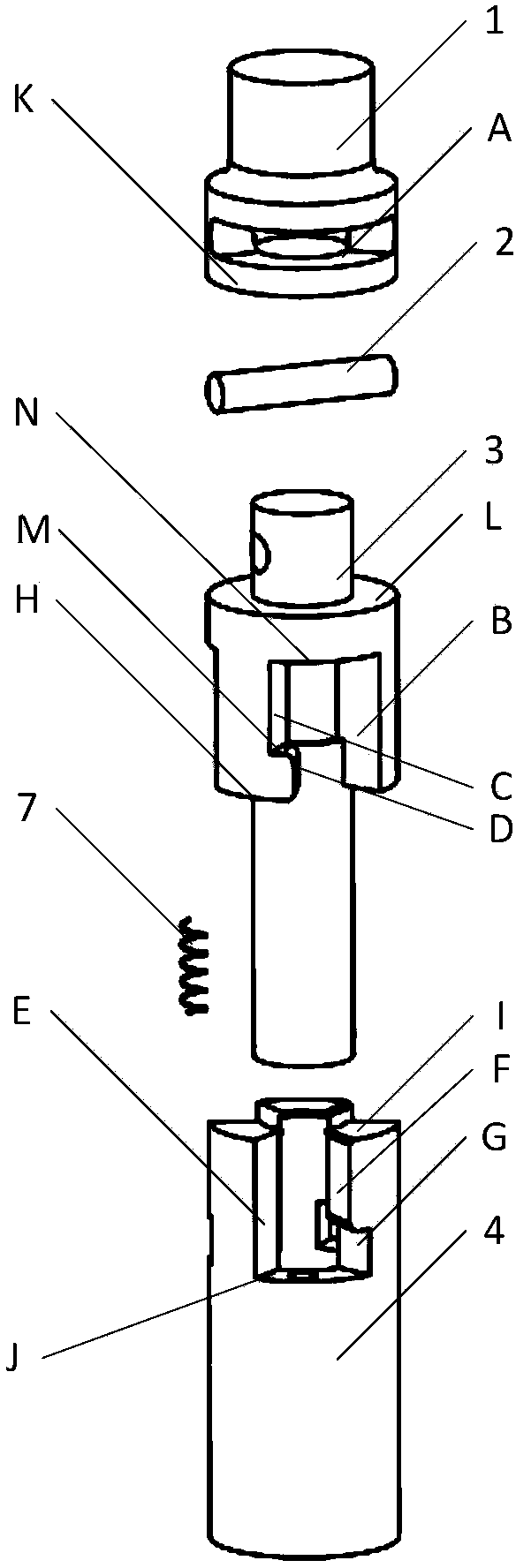

[0040] Drill tool butt joint components such as figure 1 , figure 2 As shown, it includes a power transmission joint 1, a torque transmission pin 2, a coring pipe butt joint 3, a drill pipe butt joint 4, and a butt spring 7 connected in sequence.

[0041] The top of the core tube butt joint 3 penetrates through the bottom of the force transmission joint 1, and after penetration, the two can rotate relative to the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com