Gear sleeve of contact of contactor

A contact piece and connector technology, applied in the direction of fixed/insulated contact components, base/housing, etc., can solve the problems of inconvenient operation, easy falling off, needle withdrawal, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

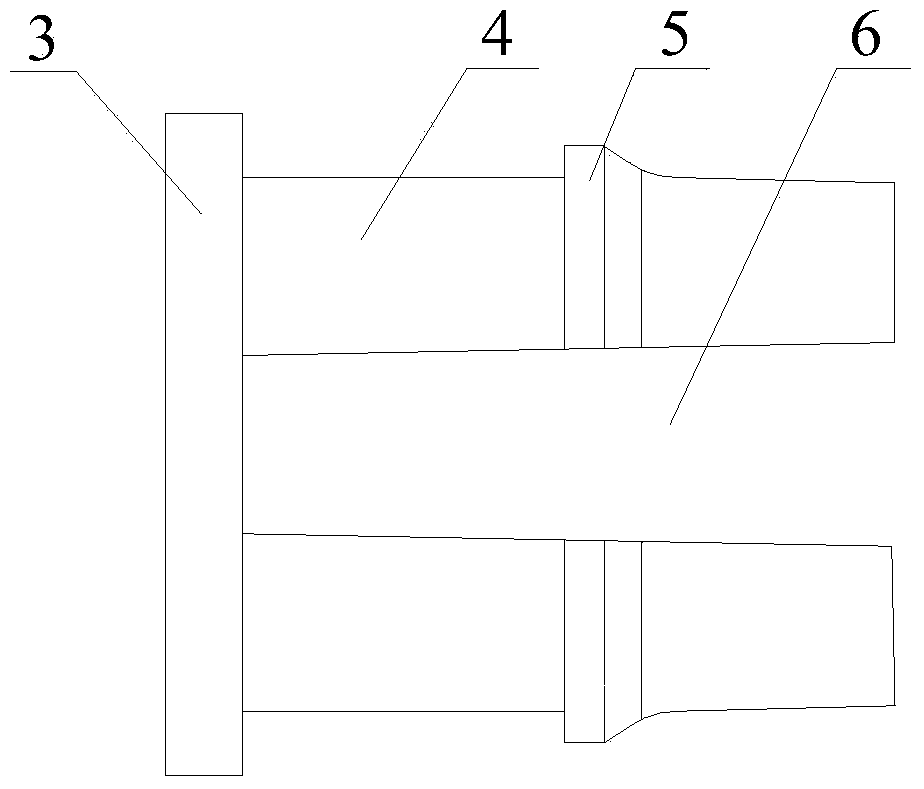

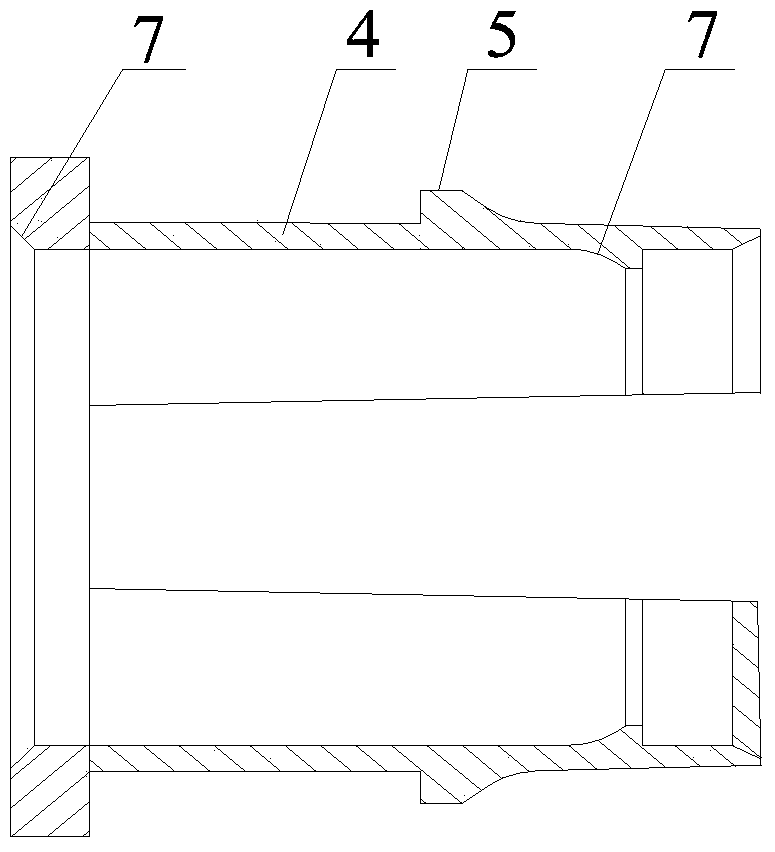

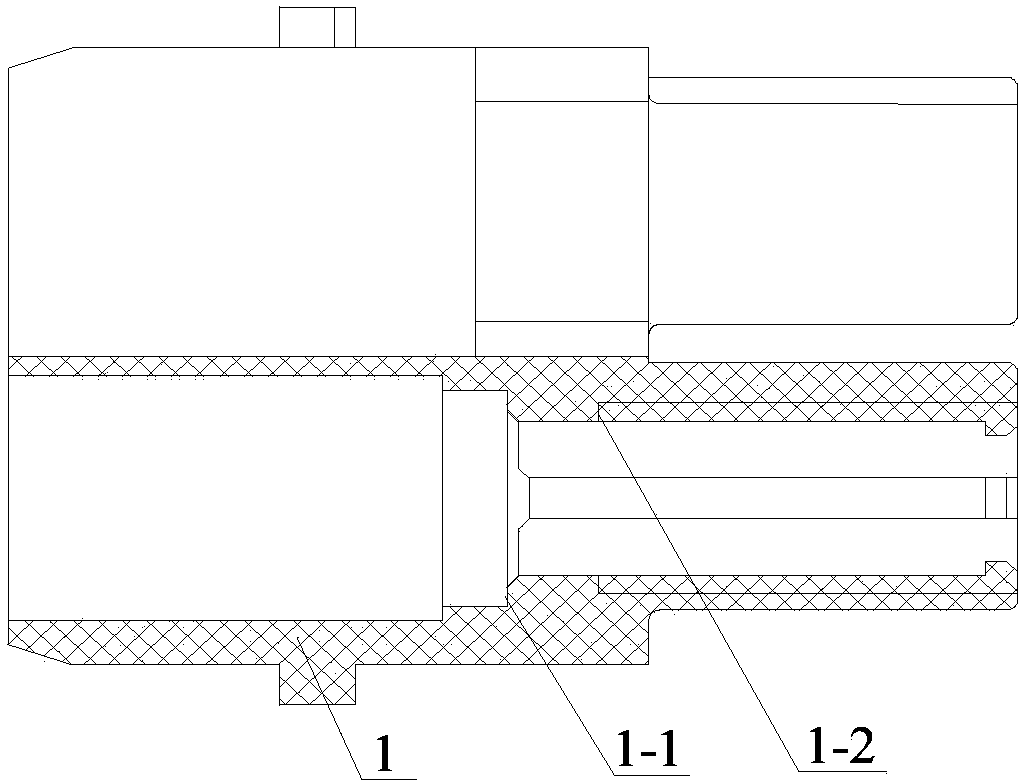

[0033] Such as Figure 1~5 As shown, the gear sleeve of the connector contact of the present invention mainly realizes the fixed connection between the insulator 1 and the contact 2 , and the gear sleeve is mainly composed of a bottom plate 3 and a pillar 4 . The pillar 4 is fixedly connected to the bottom plate 3 , and the pillar 4 and the bottom plate 3 in this embodiment are integrally structured. Both the bottom plate 3 and the pillar 4 are cylindrical, the bottom plate 3 and the pillar 4 are concentric cylinders, and the diameter of the bottom plate 3 is larger than the diameter of the pillar 4 . The base plate 3 is also provided with a through hole through the base plate 3 and the pillar 4, such as figure 2 As shown, the gear sleeve fits with the contact piece 2 through the through hole and is sleeved on the contact piece 2. At the same time, the gear sleeve is connected to the insulator 1 after the outer surface of the bottom plate 3 and the pillar 4 cooperate with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com