Fuel supply device

A technology of fuel supply equipment and fuel tanks, applied in liquid fuel feeders, mechanical equipment, charging systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

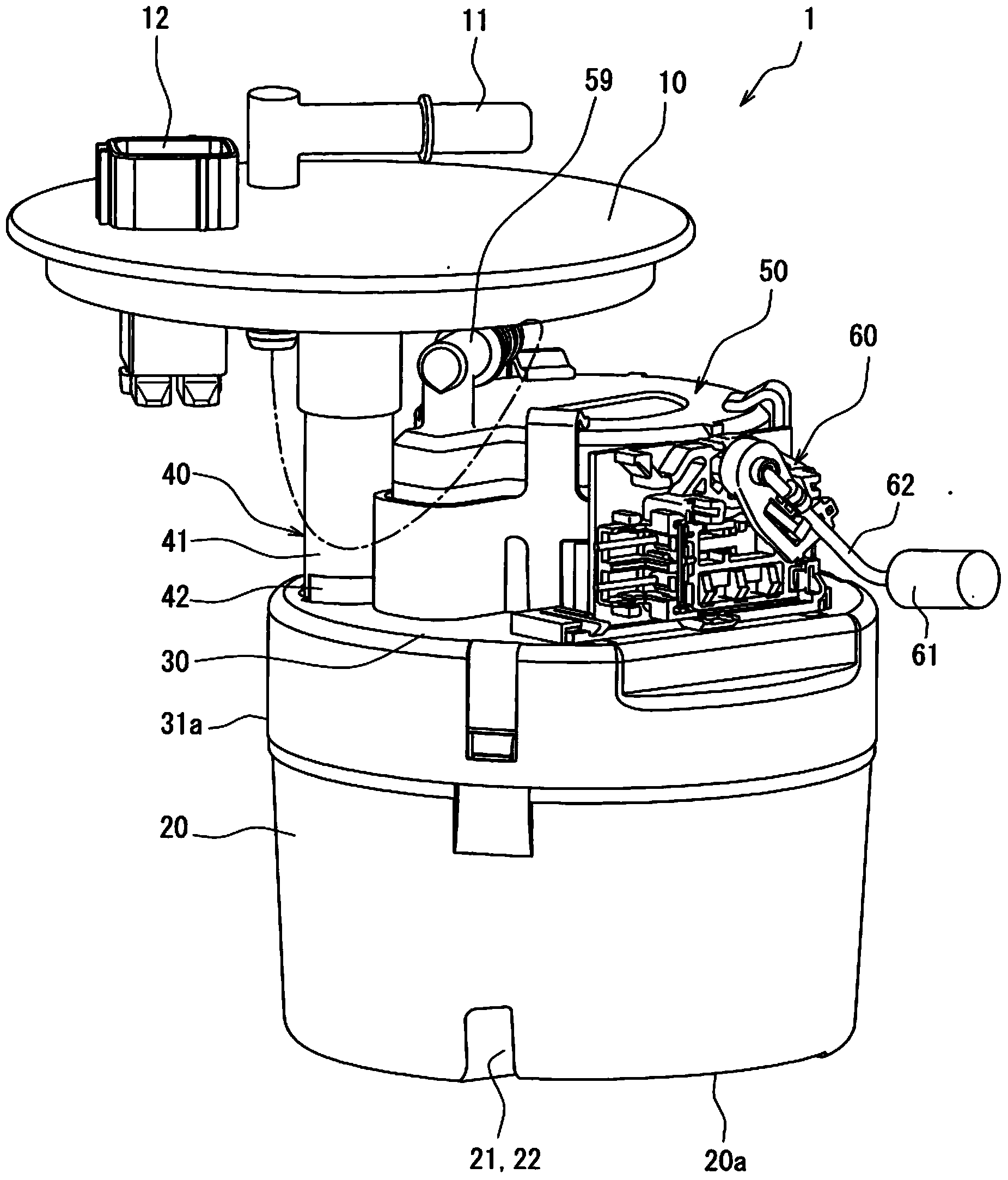

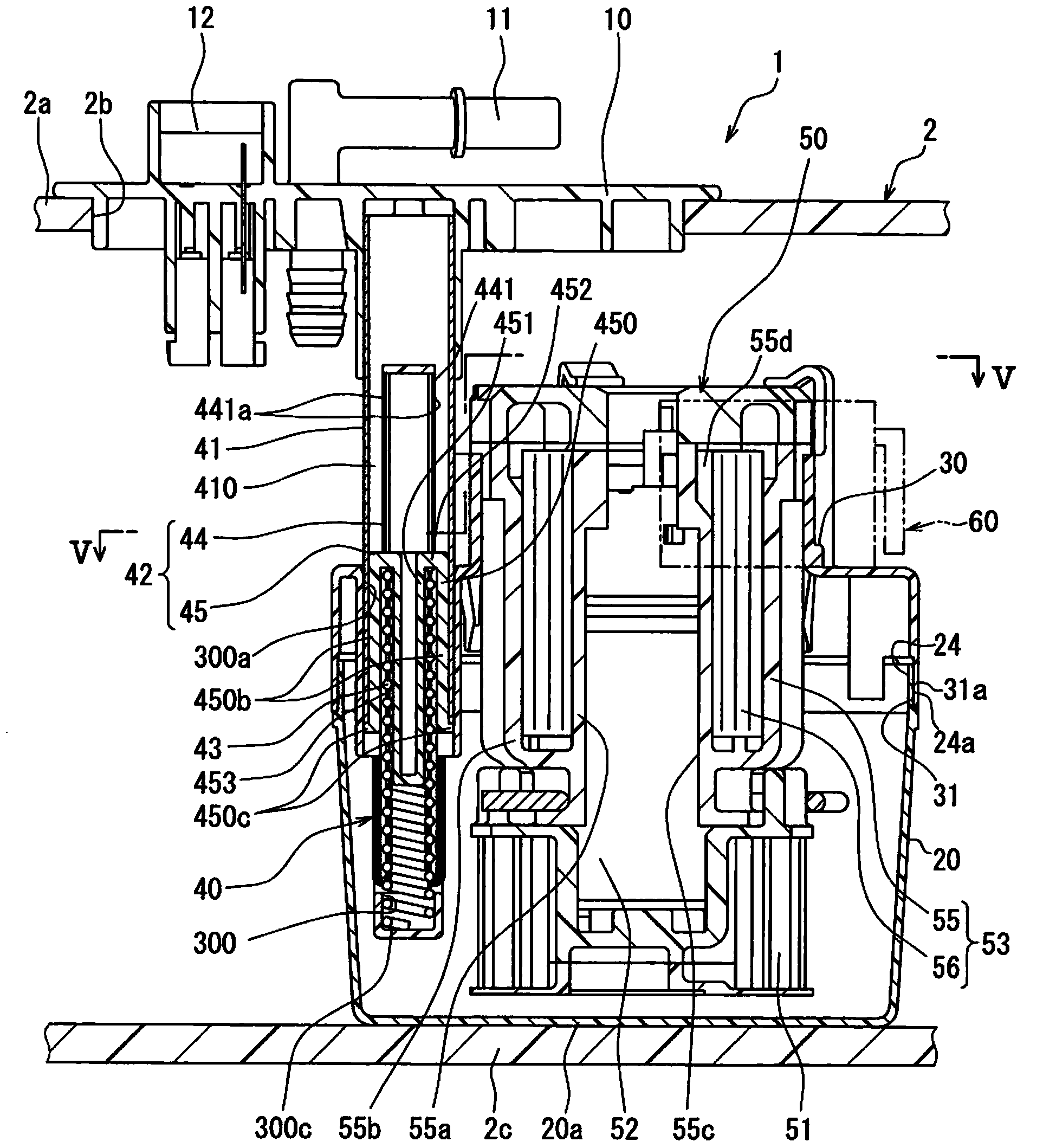

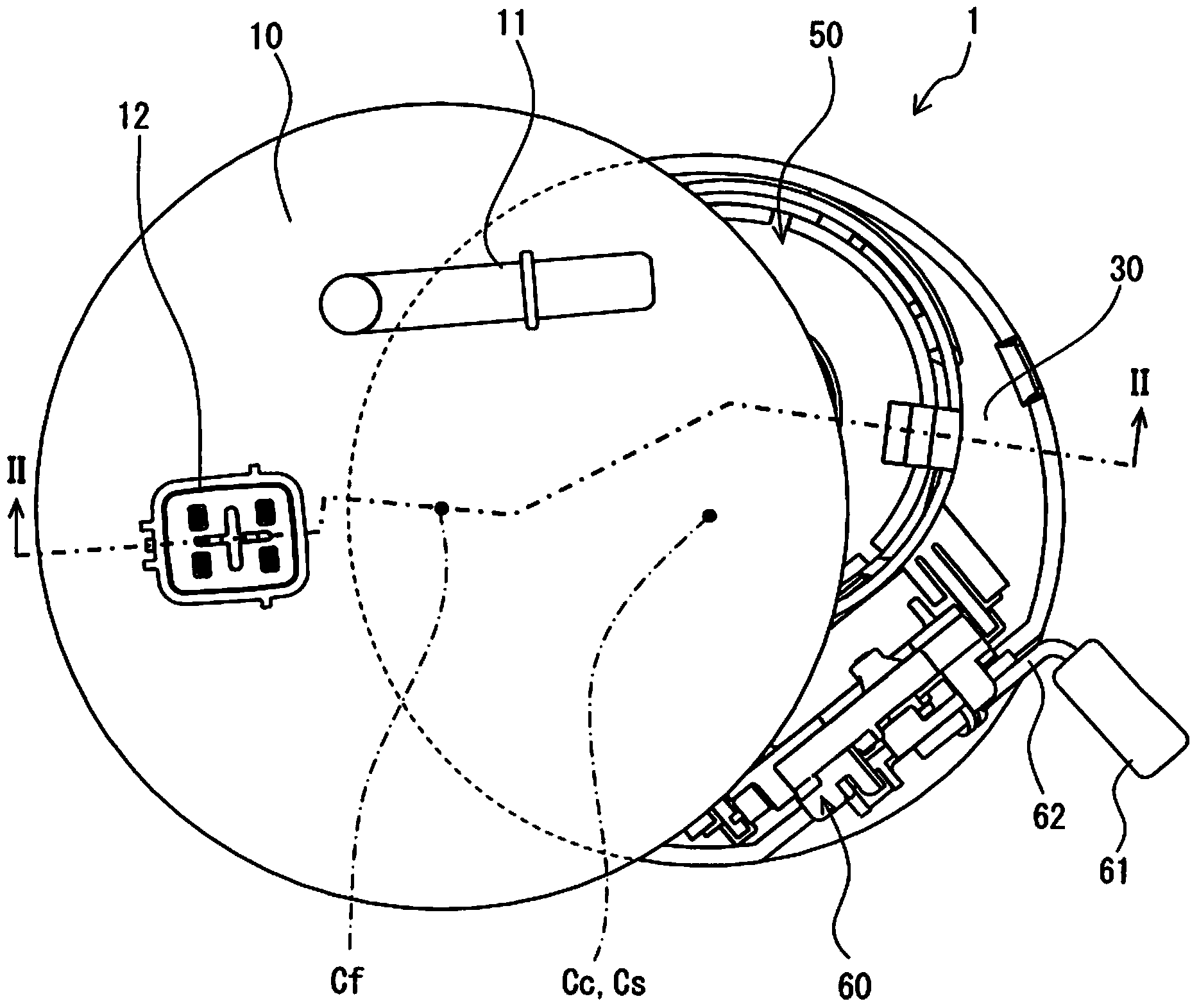

[0106] The basic structure of a fuel supply apparatus according to a first embodiment of the present invention will now be described with reference to the drawings.

[0107] figure 1 and 2 The fuel supply device 1 of the first embodiment is shown. The fuel supply device 1 is attached to a fuel tank 2 of a vehicle (such as an automobile) and supplies fuel from the fuel tank 2 to the outside. The fuel supply apparatus 1 includes a flange 10 , a sub-tank 20 , a cover member 30 , an adjustment mechanism 40 , a pump device 50 and a remaining fuel amount detection device 60 . Such as figure 2 As shown, the above-mentioned components 20 , 30 , 40 , 50 , 60 of the fuel supply device 1 are put into predetermined positions in the fuel tank 2 except for the flange 10 . figure 2 The top-to-bottom direction of is substantially coincident with the vertical direction of a vehicle parked on level ground (horizontal plane).

[0108] Such as Figures 1 to 3 As shown, the flange 10 is ma...

no. 2 example )

[0136] The basic structure of a fuel supply apparatus according to a second embodiment of the present invention will now be described.

[0137] see Figure 11 , the second embodiment is an improvement of the first embodiment. The fuel supply apparatus 1001 of the second embodiment includes a flange 1010 , a sub-tank 1020 , a pump bracket 1030 , an adjustment mechanism 1040 , a pump device 1050 , a pressure regulator 1054 and a remaining fuel amount detection device 1060 . The above-mentioned components 1020 , 1030 , 1040 , 1050 , 1054 , 1060 in the fuel supply apparatus 1001 except for the flange 1010 are put into predetermined positions in the fuel tank 2 . Figure 11 The top-to-bottom direction of is substantially coincident with the vertical direction of a vehicle parked on level ground (horizontal plane).

[0138] see Figures 11 to 13, the flange 1010 made of resin material and designed as a disc body has a return pipe 1013 in addition to the fuel supply conduit 11 and...

no. 3 example )

[0160] A characteristic structure of a fuel supply apparatus according to a third embodiment of the present invention will now be described with reference to the drawings.

[0161] Such as Figure 16 and 17 As shown, the third embodiment is an improvement of the second embodiment. That is, according to the third embodiment, the ring gasket 1070 is added to the fuel supply device of the second embodiment.

[0162] In particular, the support shaft 1041 of the third embodiment is elongated in the axial direction as compared with the second embodiment to conform to the variation in the depth of the fuel tank 2 . Because of this change, an annular gasket 1070 made of resin material and designed as a cylindrical tubular body is inserted between the flange 1010 and the elastic member 1043 in the axial direction which is the same as the mounting direction of the support shaft 1041 to the flange 1010 coincide. Therefore, when adjusting the axial thickness (axial length) of the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com