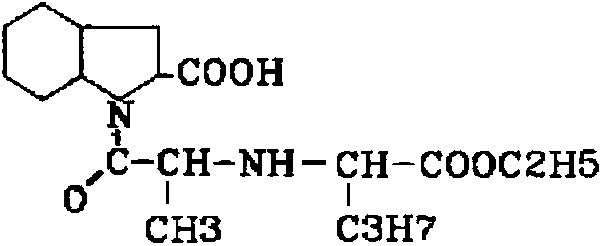

Efficient perindopril tablet and production process thereof

A technology of indopril tablet and production process, applied in the field of high-efficiency perindopril tablet and its production process, can solve the problems of nephrotoxicity, loss of taste, less adverse reactions and the like, and achieve prevention, development, control Blood pressure, the effect of controlling the occurrence of kidney disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

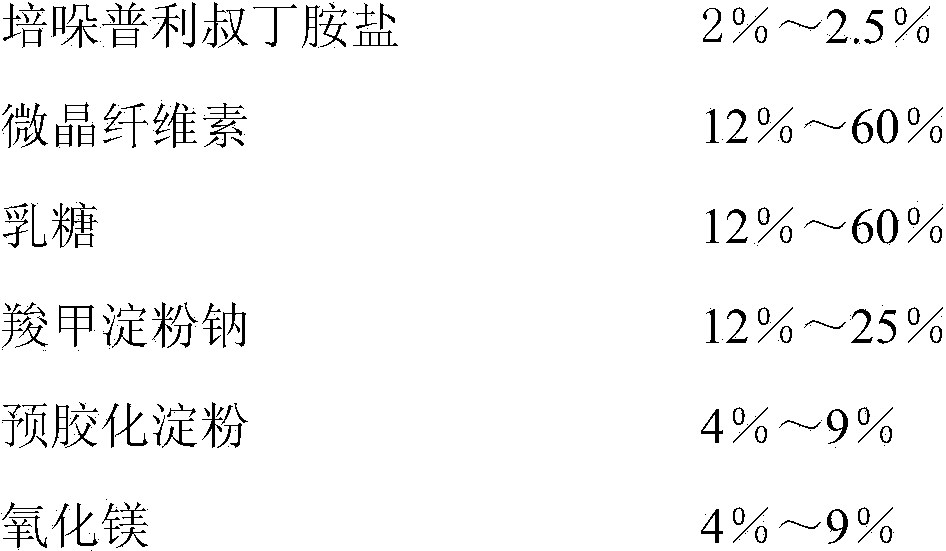

[0026] A high-efficiency perindopril tablet comprises the following components:

[0027]

[0028] Finally, a tablet with a total tablet weight of 70-80 mg is obtained, and its preparation process comprises the following steps:

[0029] (1) Perindopril tert-butylamine salt is successively mixed with sodium starch glycolate, lactose, and magnesium oxide in equal amounts;

[0030] (2) above-mentioned mixture is mixed with microcrystalline cellulose;

[0031] (3) Add an appropriate amount of binder to make soft materials, and dry and granulate at 70°C;

[0032] (4) Add additional auxiliary materials and mix for 45 minutes;

[0033] (5) Sampling and testing the content and content uniformity of intermediate products, ∮6mm punch for tableting, aluminum-plastic packaging.

Embodiment 2

[0035] A high-efficiency perindopril tablet comprises the following components:

[0036]

[0037] Finally, a tablet with a total tablet weight of 70-80 mg is obtained, and its preparation process comprises the following steps:

[0038] (1) Perindopril tert-butylamine salt is successively mixed with sodium starch glycolate, lactose, and magnesium oxide in equal amounts;

[0039] (2) above-mentioned mixture is mixed with microcrystalline cellulose;

[0040] (3) Add an appropriate amount of adhesive to make soft materials, and carry out drying and sizing at 50°C;

[0041] (4) Add additional auxiliary materials and mix for 15 minutes;

[0042] (5) Sampling and testing the content and content uniformity of intermediate products, ∮6mm punch for tableting, aluminum-plastic packaging.

Embodiment 3

[0044] A high-efficiency perindopril tablet comprises the following components:

[0045]

[0046]

[0047] Finally, a tablet with a total tablet weight of 70-80 mg is obtained, and its preparation process comprises the following steps:

[0048] (1) Perindopril tert-butylamine salt is successively mixed with sodium starch glycolate, lactose, and magnesium oxide in equal amounts;

[0049] (2) above-mentioned mixture is mixed with microcrystalline cellulose;

[0050] (3) Add an appropriate amount of adhesive to make soft materials, and dry and granulate at 60°C;

[0051] (4) Add additional auxiliary materials and mix for 30 minutes;

[0052] (5) Sampling and testing the content and content uniformity of intermediate products, ∮6mm punch for tableting, aluminum-plastic packaging.

[0053] Below in conjunction with specific clinical use the present invention will be further described:

[0054] 1.1 Case selection

[0055]Randomly select 60 patients who meet the 1999 WHO / I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com