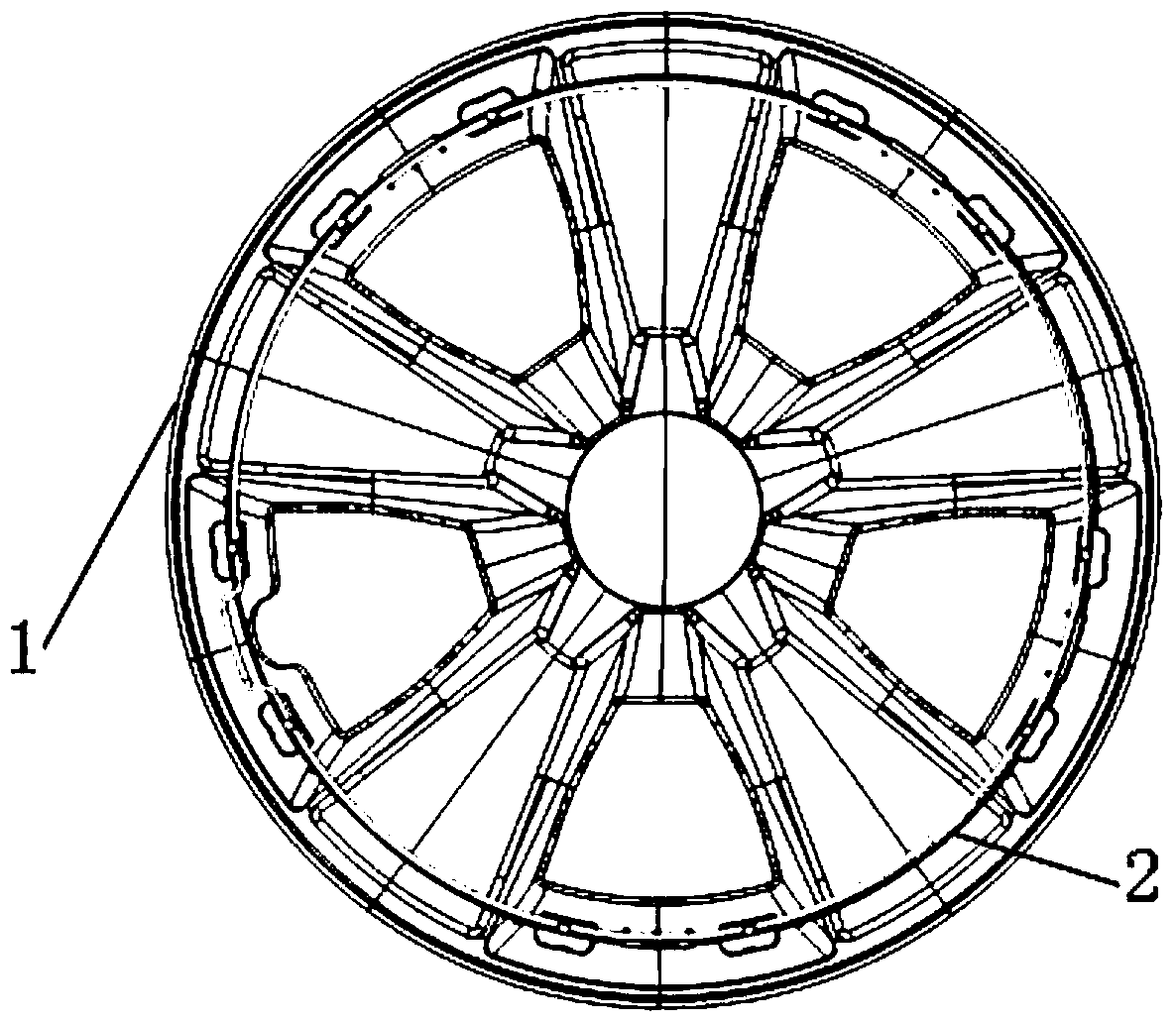

Wheel cover structure

A wheel cover and wheel technology, applied in the direction of wheels, wheel cover discs, vehicle parts, etc., can solve the problems of potential safety hazards and low assembly reliability, and achieve the effects of good firmness, good stability, light weight and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are described below through specific examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be interpreted as limitations to the technical solutions of the present invention.

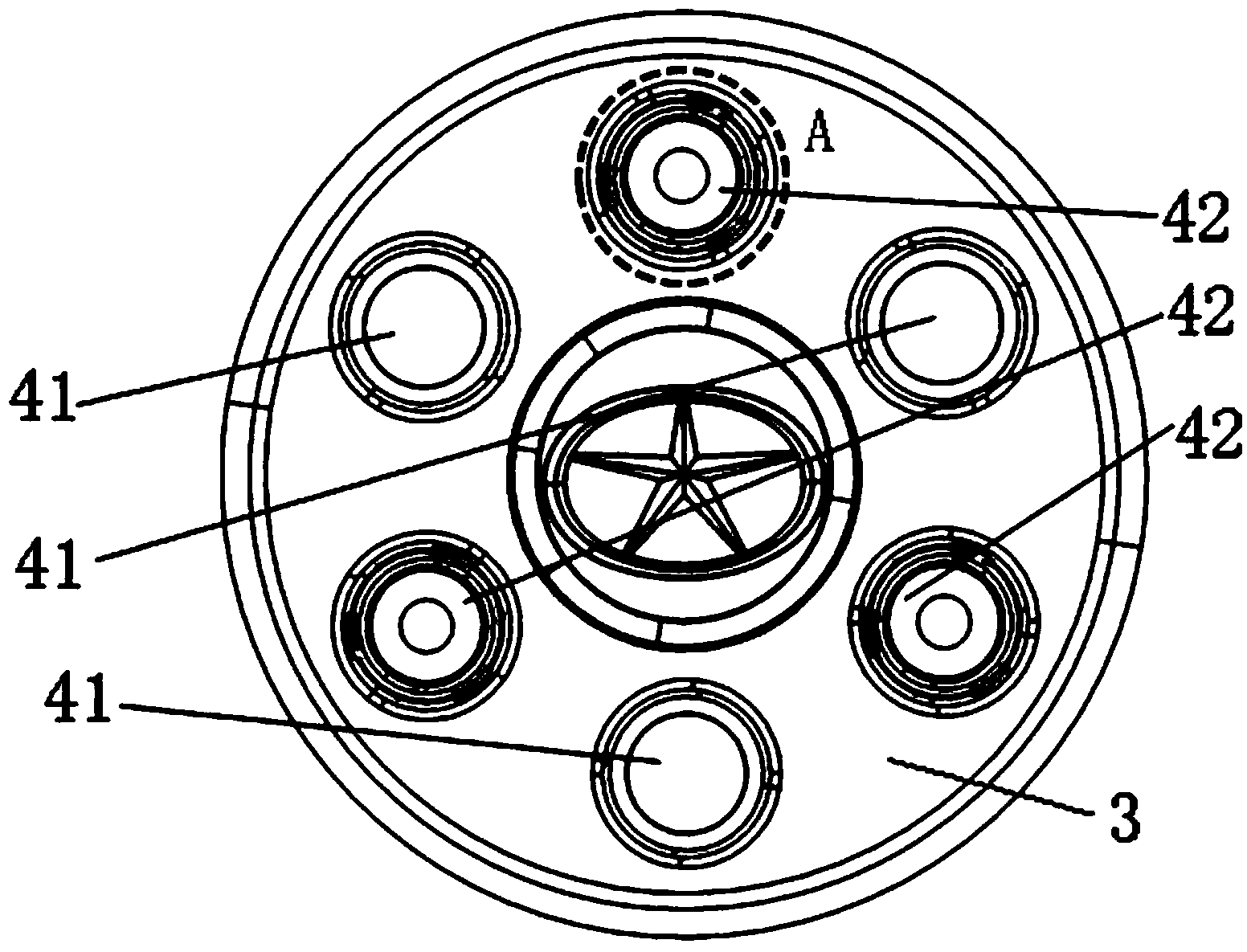

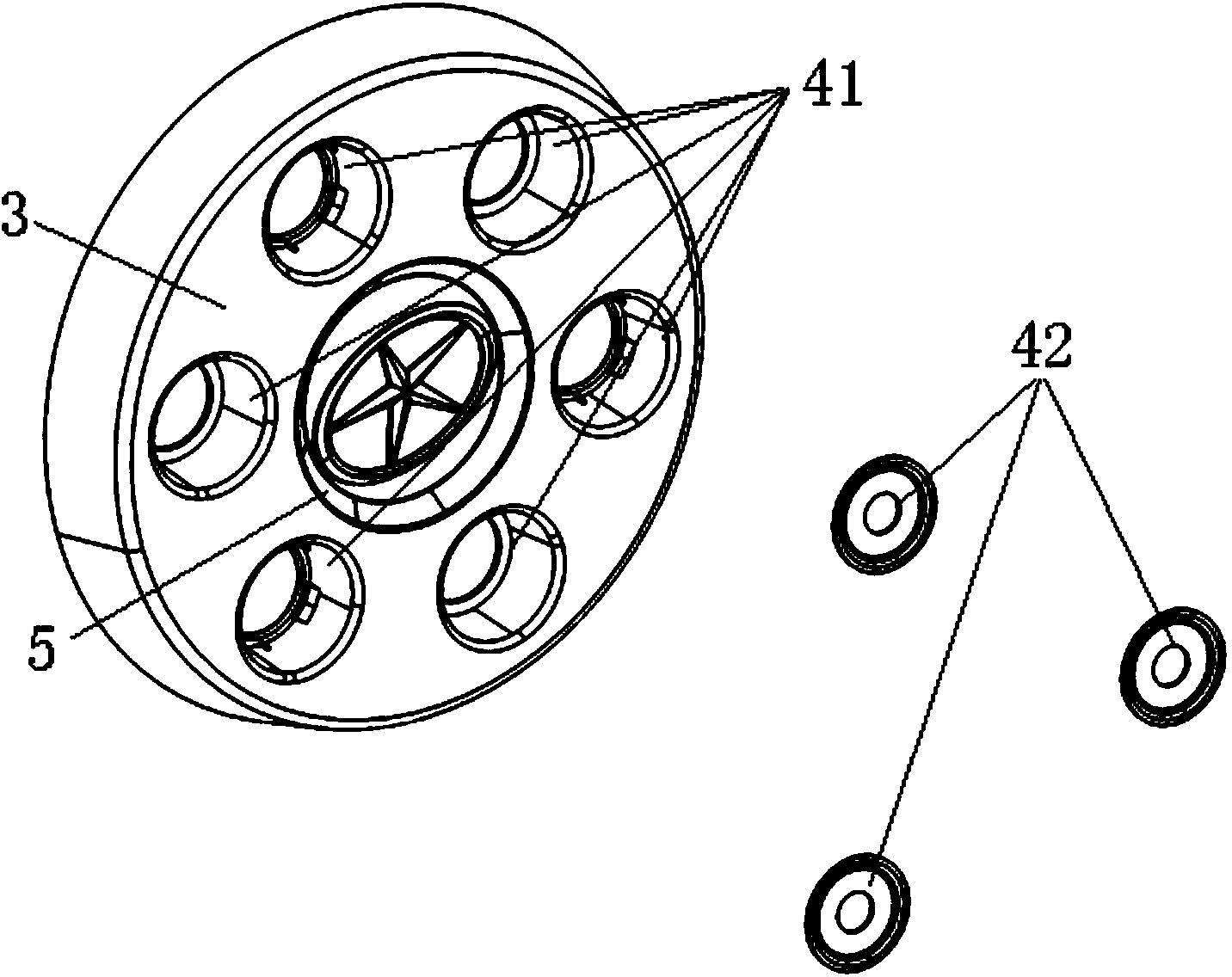

[0029] Such as Figure 2 to Figure 6 As shown, the novel wheel cover structure of the present invention is composed of a wheel cover body 3 and three stamping washers 42; the wheel cover body 3 is a circular cover structure, and the diameter of the cover bottom is slightly smaller than the opening diameter; the center of the cover bottom is provided with An inwardly concave circular groove structure 5 is decorated with patterns; the circular groove structure 5 can cover the wheel mounting axle head.

[0030] In this application, all inwards are pointing towards the rim of the wheel.

[0031] There are six inward small grooves 41 uniformly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com