A Hybrid Drive System Based on Synchronizer Coupling with Dual Clutch DCT

A dual-clutch, hybrid power technology, which is applied to the layout of multiple prime movers, power devices, and air pressure power devices of general power devices, and can solve problems such as inability to adjust the speed of the motor and large capacity of the motor power battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

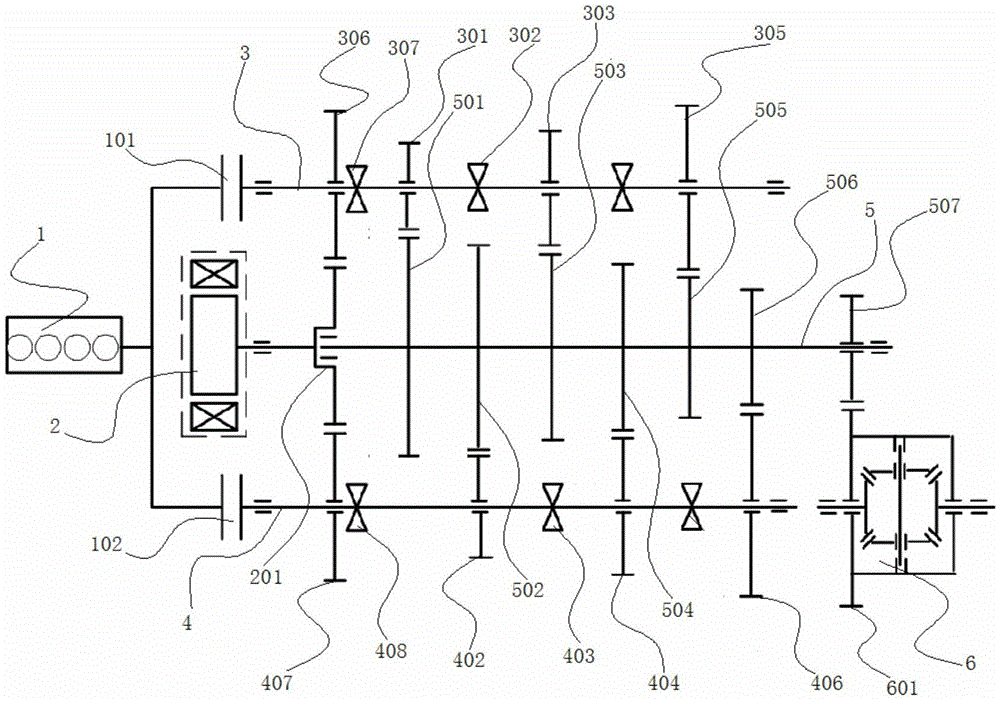

[0019] A hybrid drive system based on a synchronizer-coupled dual-clutch DCT includes an internal combustion engine 1 , an ISG motor 2 , an input shaft 3 for odd gears, an input shaft 4 for even gears, and an output shaft 5 .

[0020] The output shaft of the internal combustion engine 1 is connected to the input end of a dual clutch, and the dual clutch includes a first clutch 101 and a second clutch 102 . In the embodiment, the driving gear installed on the output shaft of the internal combustion engine 1 simultaneously drives two driven gears to rotate, and the installation shafts of the two driven gears are respectively connected to the output ends of the first clutch 101 and the second clutch 102, In this way, the output shaft of the internal combustion engine 1 is connected in parallel with the dual-clutch structure. The output end of the first clutch 101 is connected to the odd-numbered gear input shaft 3 , and the output end of the second clutch 102 is connected to the ...

Embodiment 2

[0026]This embodiment is based on the synchronizer-coupled dual-clutch DCT hybrid drive system disclosed in Embodiment 1, through the power coupling / decoupling of the motor and the internal combustion engine, that is, through the separation / decoupling of the odd-numbered gear synchronizer 307 and the even-numbered gear synchronizer 408 Engage multiple drive modes for hybrid drive systems:

[0027] 1) Pure electric mode: the internal combustion engine 1 is stopped, the first clutch 101 and the second clutch 102 are both in the disengaged state, and the ISG motor 2 is in the driving mode and rotates forward. When traveling with odd-numbered gears, the odd-numbered gear driven gear 306 is locked on the odd-numbered gear input shaft 3, and the even-numbered gear driven gear 407 is unlocked with the even-numbered gear input shaft 4. The motor gear 201 transmits to the driven gear 306 of odd gears, and the motor gear 201 does not transmit to the driven gear 407 of even gears. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com