Transmission for a motor vehicle

A technology of transmission and motor vehicle, applied in the field of power transmission system, can solve problems such as affecting the service life of multi-plate clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

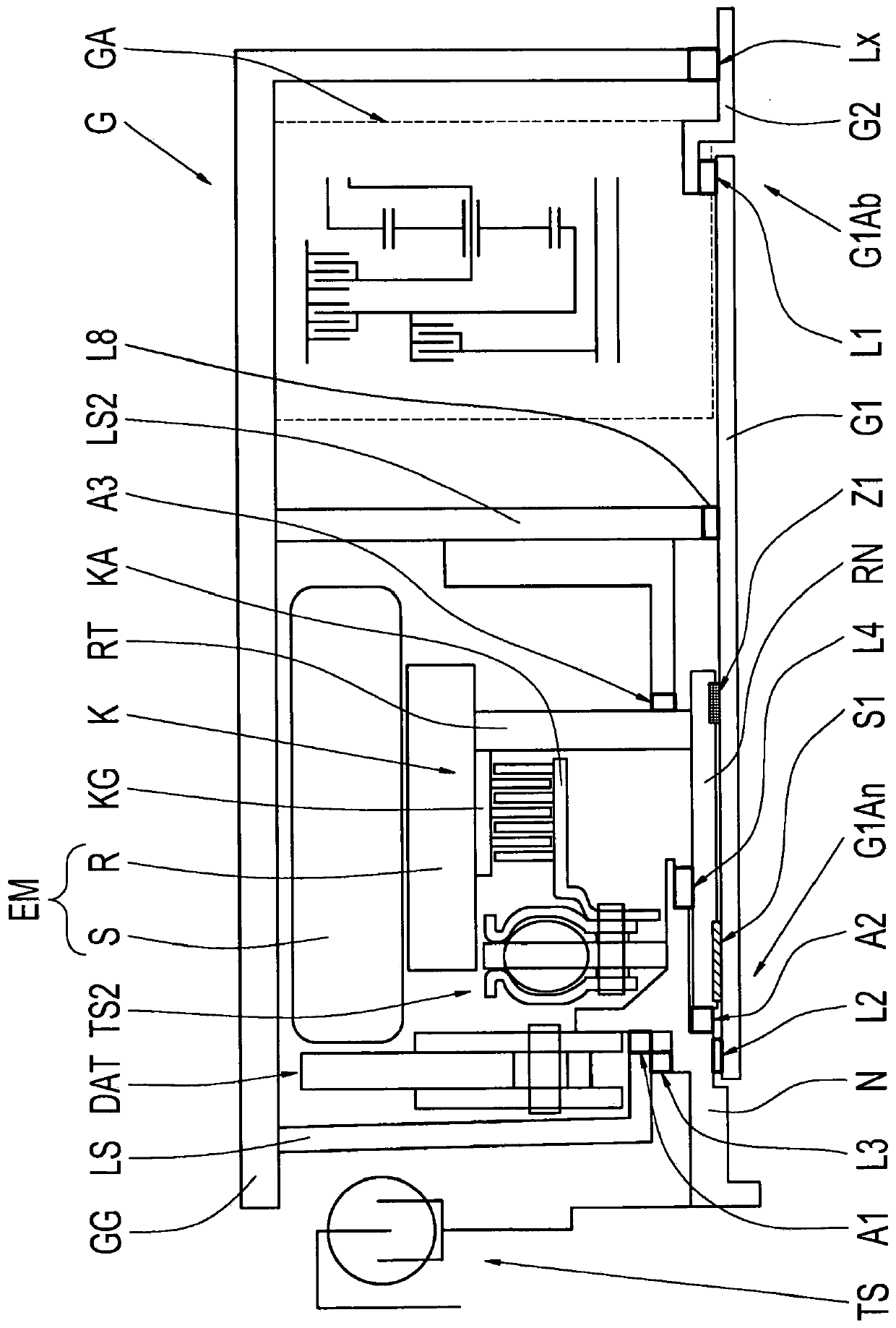

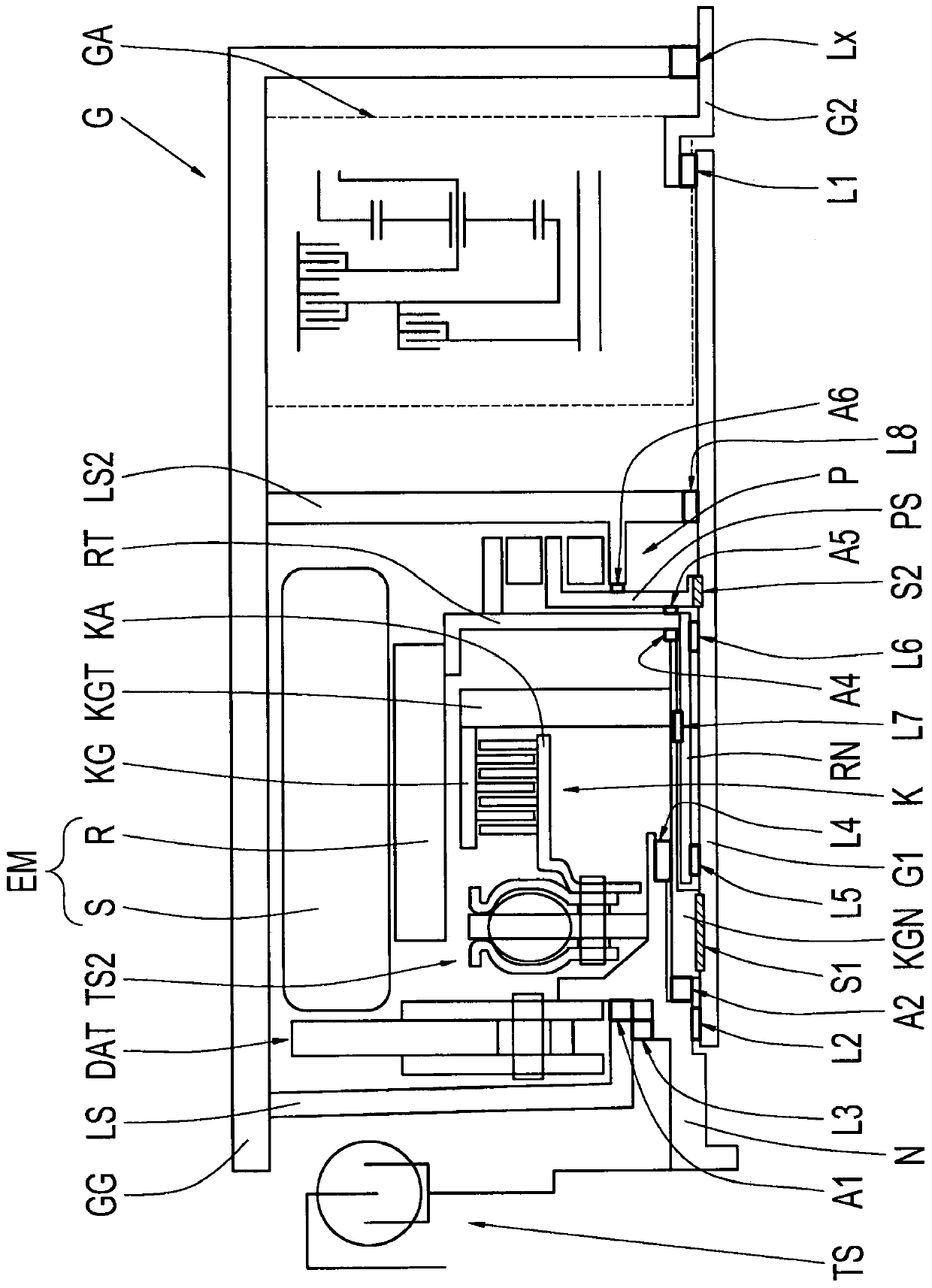

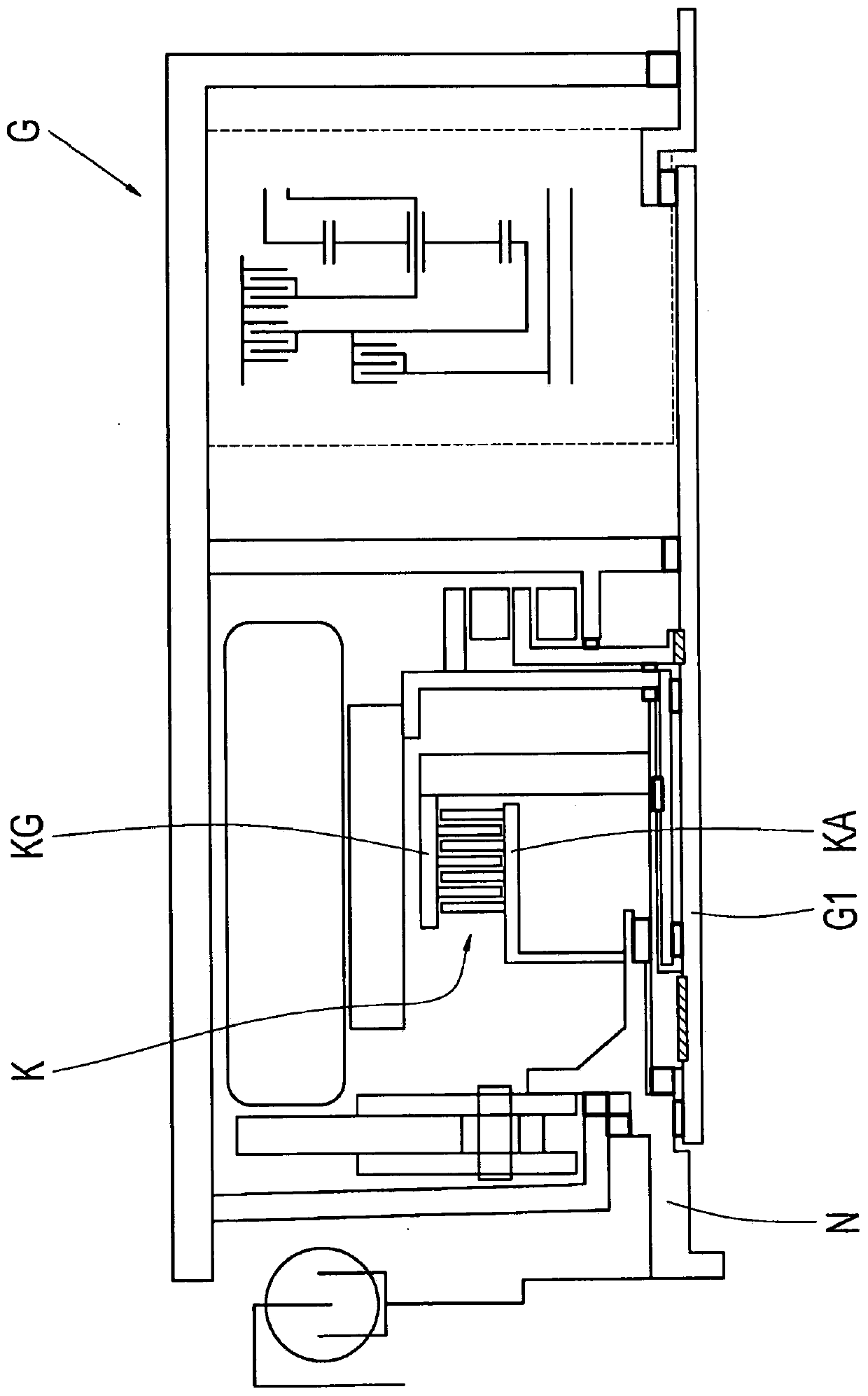

[0026] figure 1 A schematic diagram of a first embodiment of the transmission G is shown. The transmission G has a drive shaft G1, a driven shaft G2 and a gear changing device GA, which is in figure 1 only implied. The gear change device GA is designed to provide different gear ratios between the drive shaft G1 and the output shaft G2 , for example by means of planetary gear sets and shift elements interacting with the planetary gear sets.

[0027] The transmission G also has a housing GG, a hub N, a disconnect clutch K (comprising a first clutch half KA and a second clutch half KG) and an electric machine EM (comprising a rotatable rotor R and a non-rotatable stator relative to the housing GG S). The separating clutch K is designed as a wet-running multi-plate clutch by way of example, with the aid of suitable figure 1 An actuating device not shown in can be actuated, for example by means of a hydraulically actuatable piston. The hub N is connected to the torsional vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com