Lifting cup support

A technology for a cup holder and a lifting bracket, applied in the field of cup holders, can solve the problems of poor stability and clamping performance, large volume, complex structure, etc., and achieve the effect of reducing design difficulty and manufacturing cost, ensuring performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

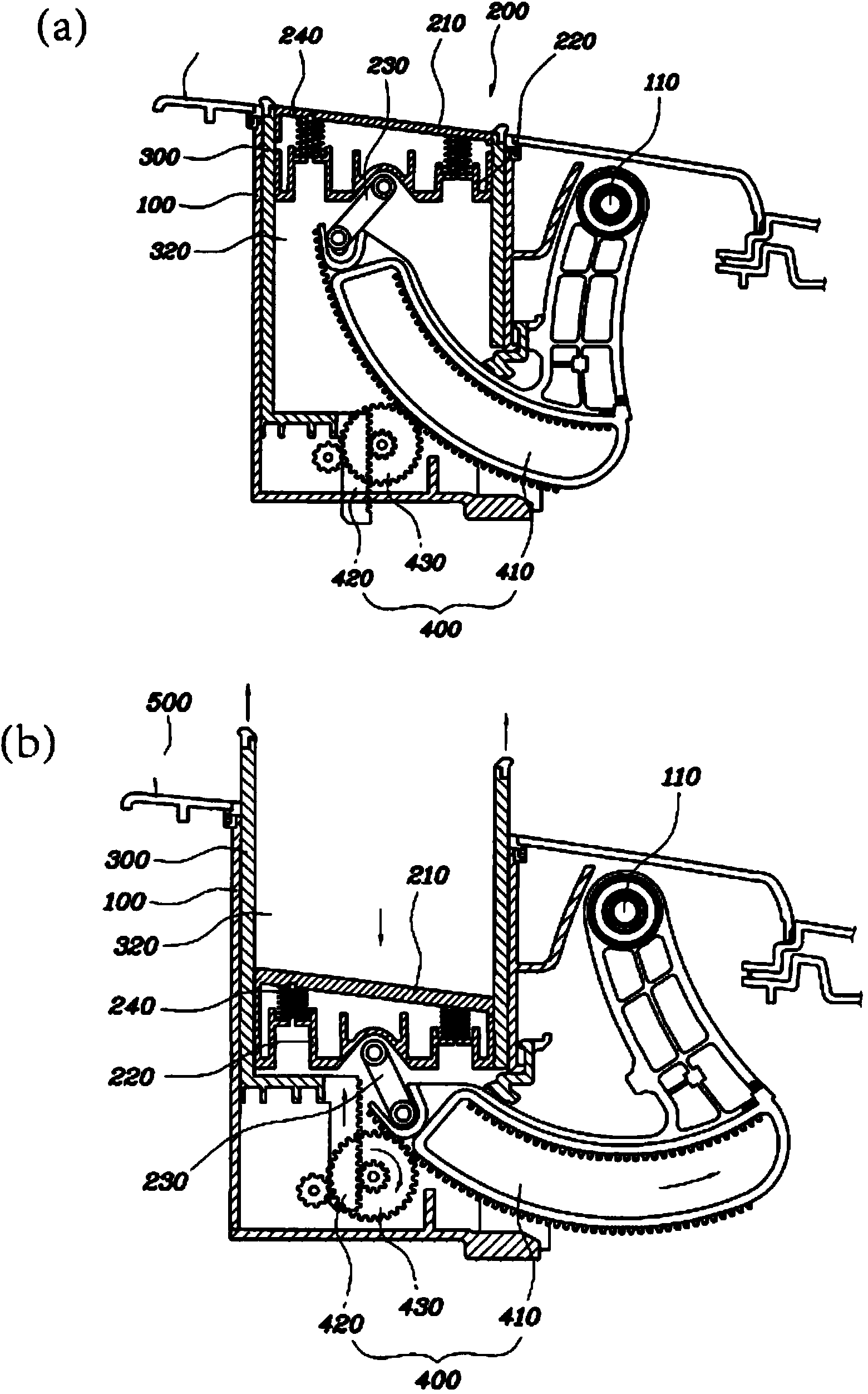

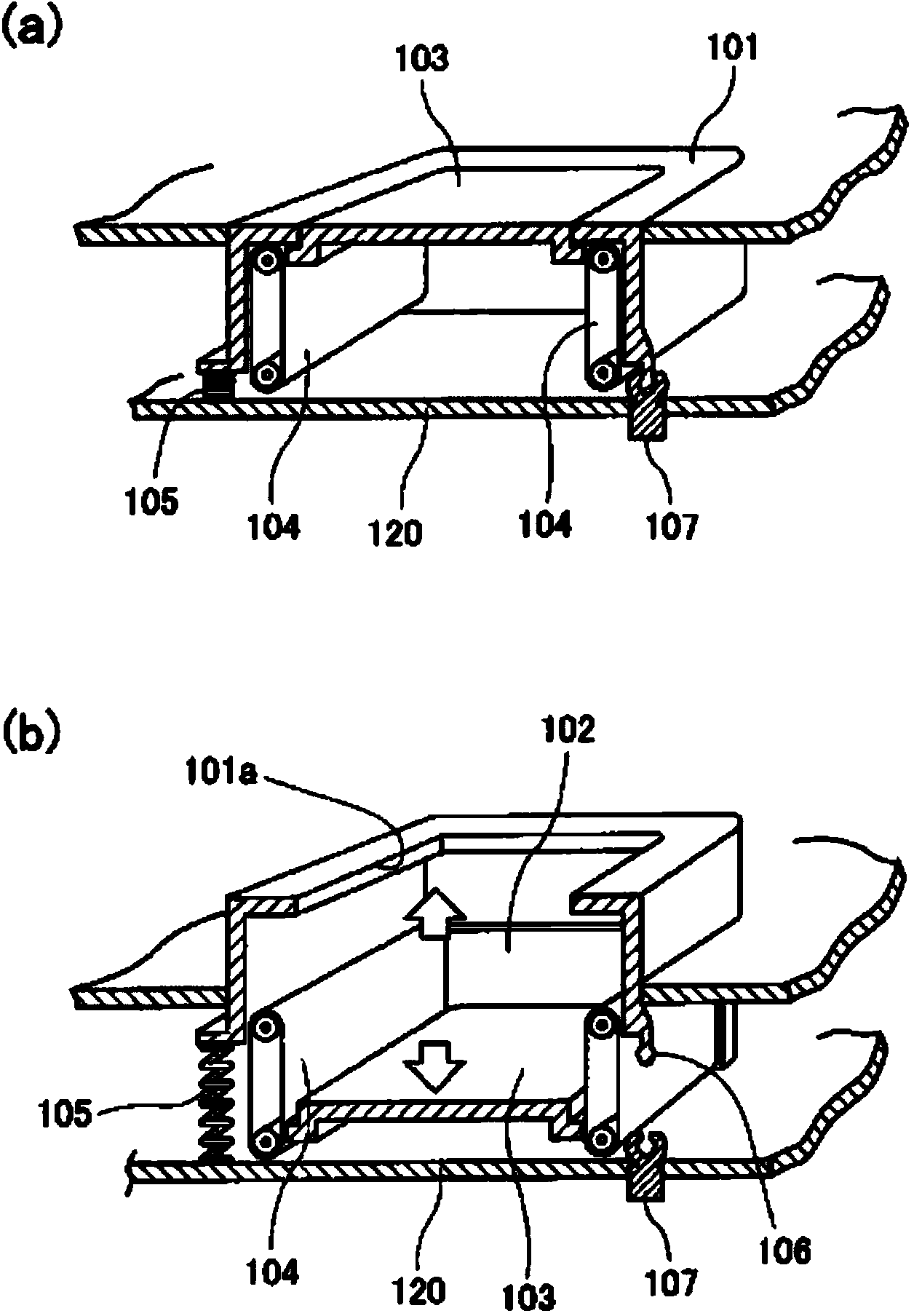

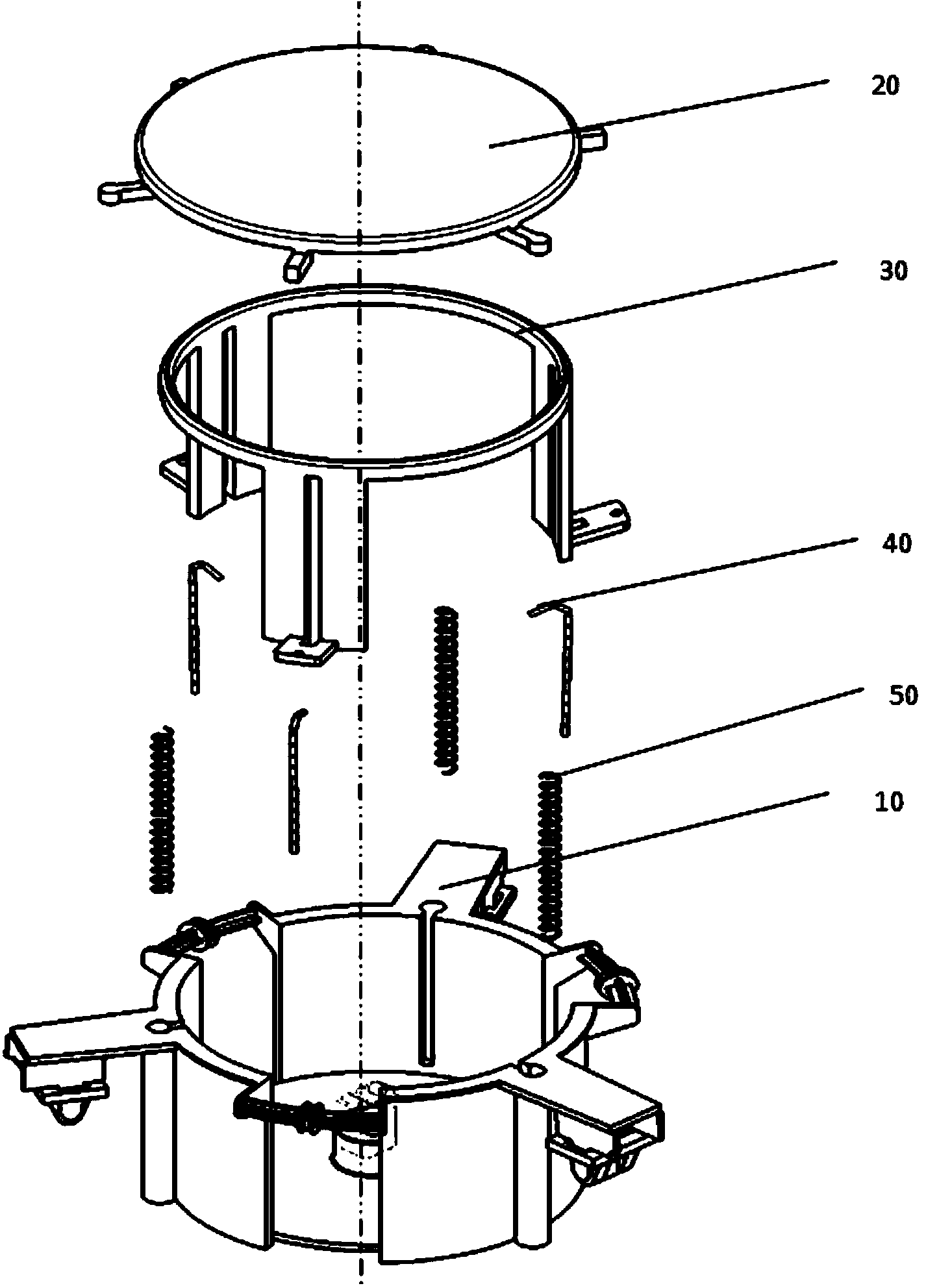

[0028] Such as Figure 3-Figure 9 Shown is a lifting cup holder according to a preferred embodiment of the present invention, which is shown as a trisection symmetrical structure centered on the central axis, including: a supporting shell 10, a tray 20, a lifting bracket 30, a pull cord 40 and Spring 50.

[0029] Wherein, the structure of tray 20 is as follows: Figure 4 As shown, it includes a substantially circular tray body 25, and the snap joint 21 (see Figure 8 ), and bolt joints 22 and pressure heads 23 extending from the outer periphery of the tray body 25 at regular intervals. In this embodiment, there are preferably three bolt joints 22 and pressure heads 23 respectively. Preferably, the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com