Adjustment of suction air to match sheet format

A technology of sheets and suction beams, applied in the field of equipment for oriented sheet-shaped components, which can solve the problems of high wear of connecting cables, high movement quality, fault sensitivity and time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

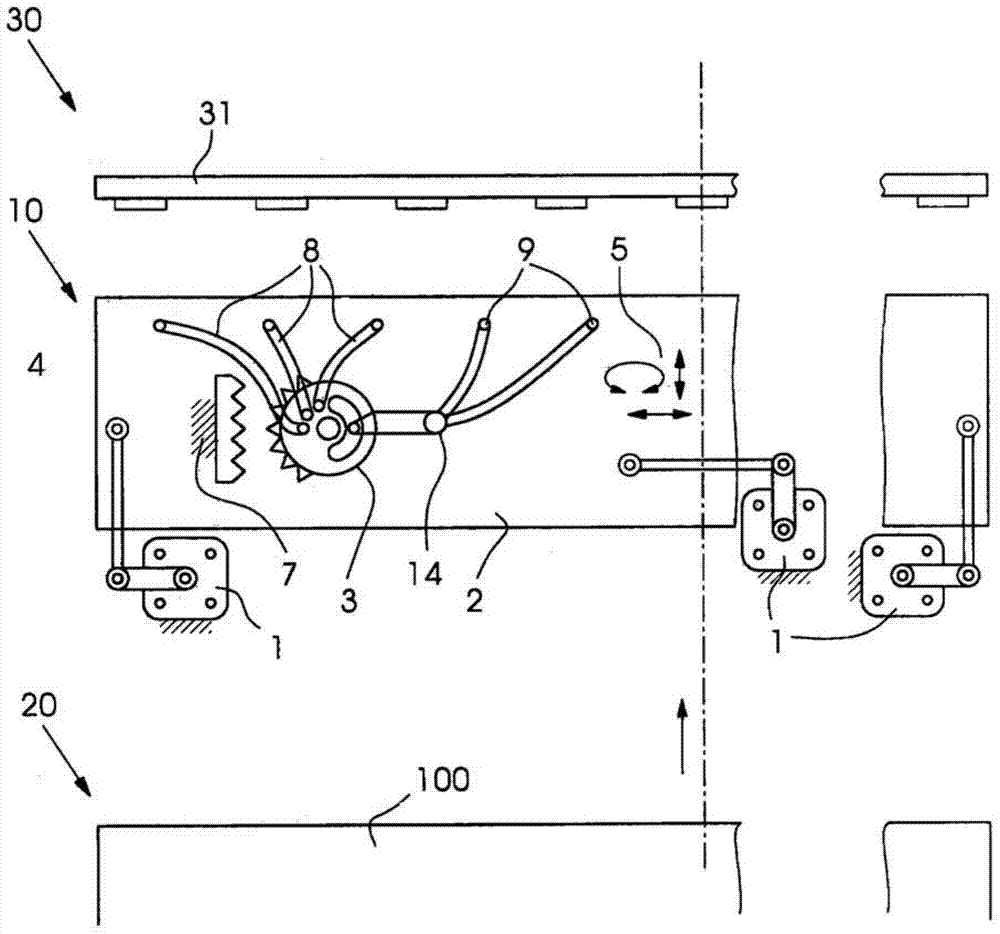

[0022] figure 1 The orientation device 10 is shown in a view from below, which, viewed in the transport direction T, is arranged between the feeder 20 and the sheet processing machine 30 . The sheets 100 from the feeder 20 are grasped by the orientation device 10 , aligned and forwarded to the gripper 31 of the sheet processing machine 30 .

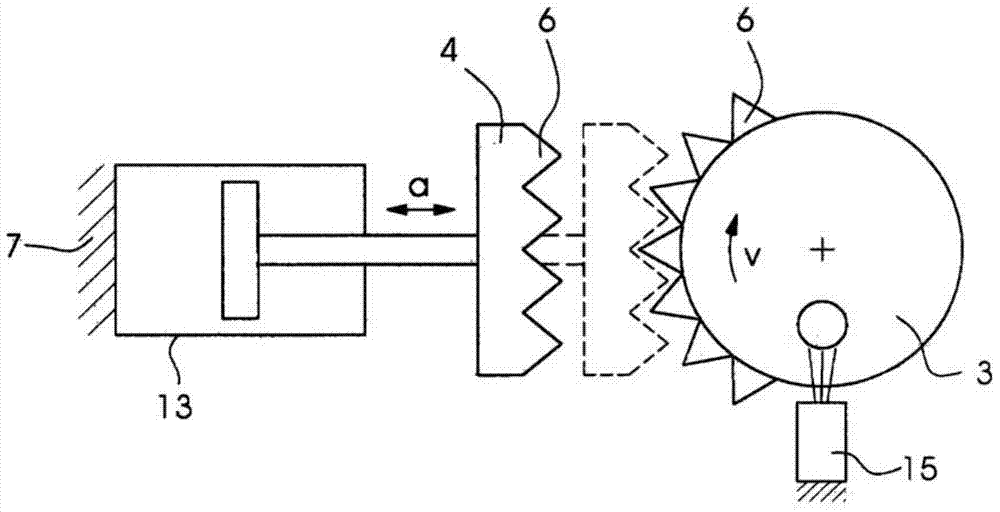

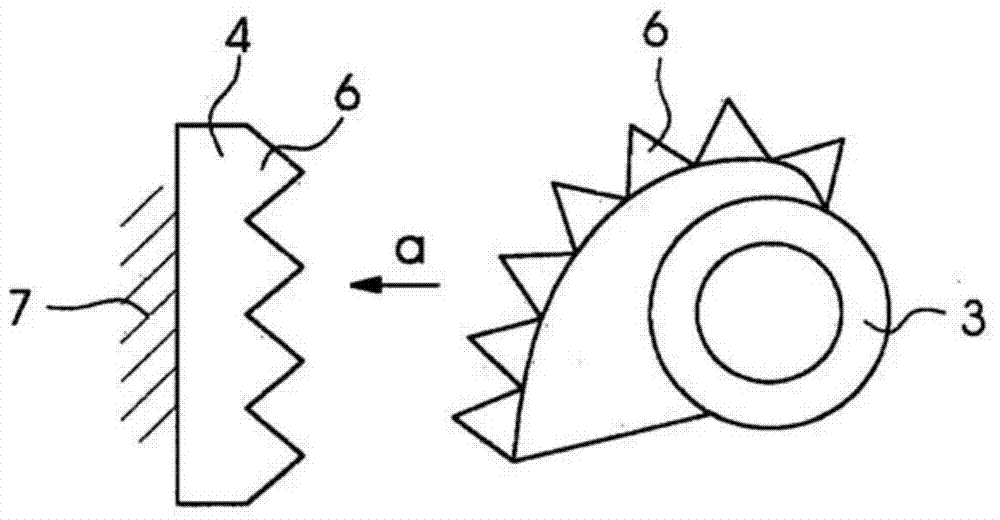

[0023] The orientation device 10 has a contact element 2 which figure 1 In an embodiment, it is configured as a suction plate. The contact element 2 is formed symmetrically with respect to the center axis, wherein, at figure 1 Only one half is shown in . The contact element 2 can be moved by the three drives 1 in its degrees of freedom 5 firstly in the circumferential direction, ie in the conveying direction T, secondly transversely to the circumferential direction T and thirdly by rotation in an orientation plane, whereby The corresponding sheet 100 can be oriented. For this purpose, the contact element 2 has a plurality of suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com