Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of incomplete bottom etching, bridging, etc., to reduce the possibility of shrinkage at the bottom of openings and defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for manufacturing a semiconductor device according to an embodiment of the present invention will be described below. However, it can be easily understood that the embodiments provided in the present invention are only used to illustrate the making and use of the present invention in a specific way, and are not intended to limit the scope of the present invention. Furthermore, in the drawings and descriptions of the embodiments of the present invention, the same reference numerals are used to denote the same or similar components.

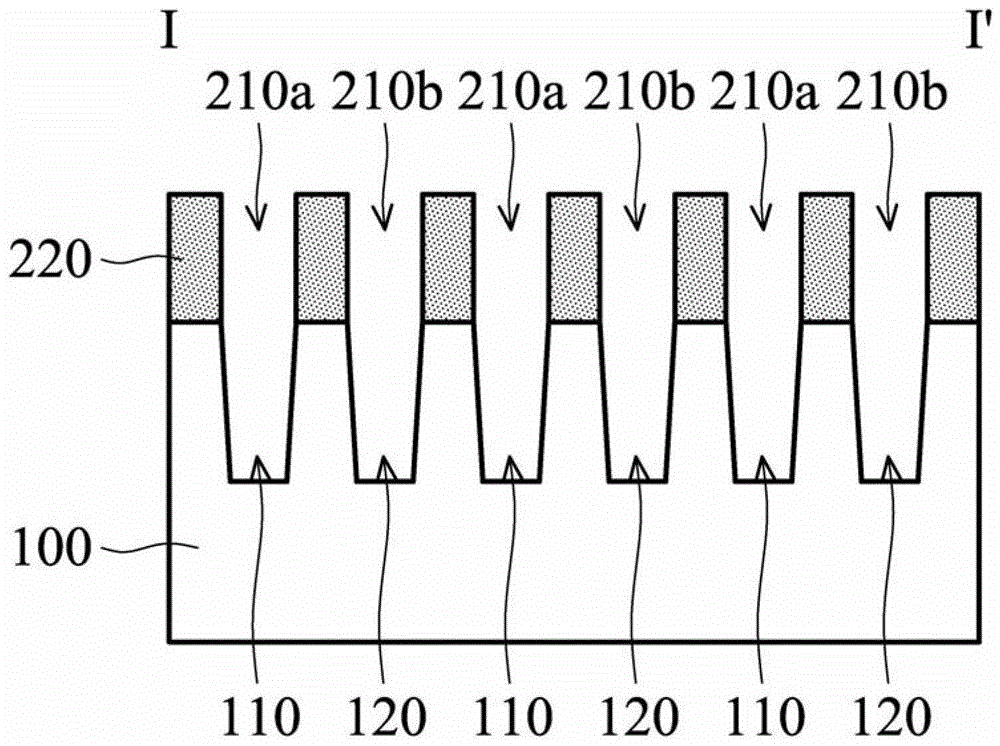

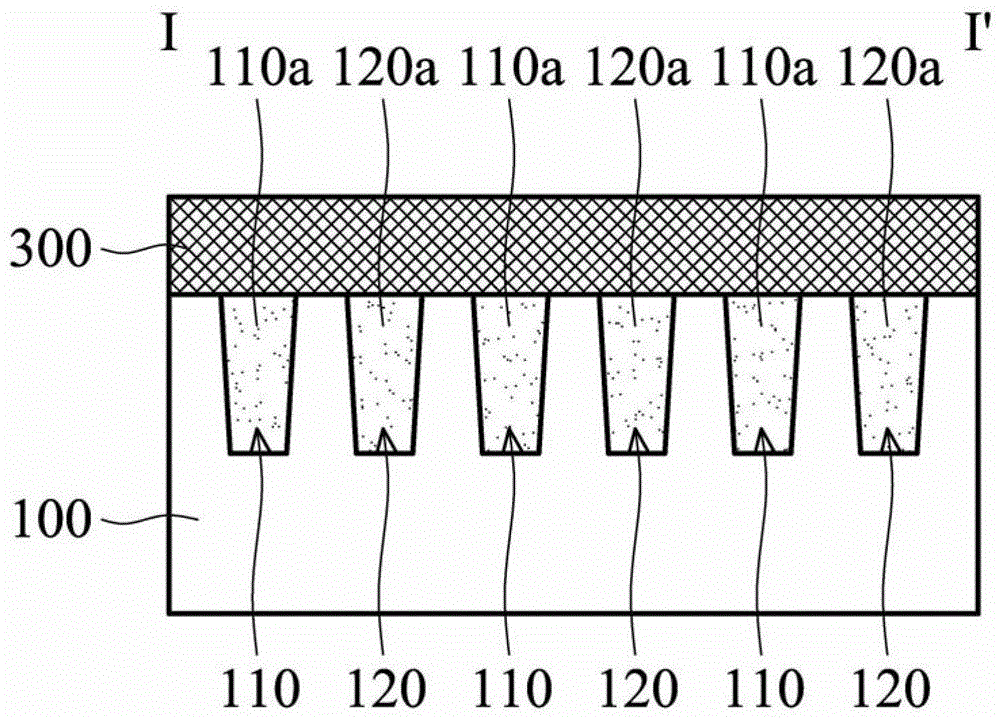

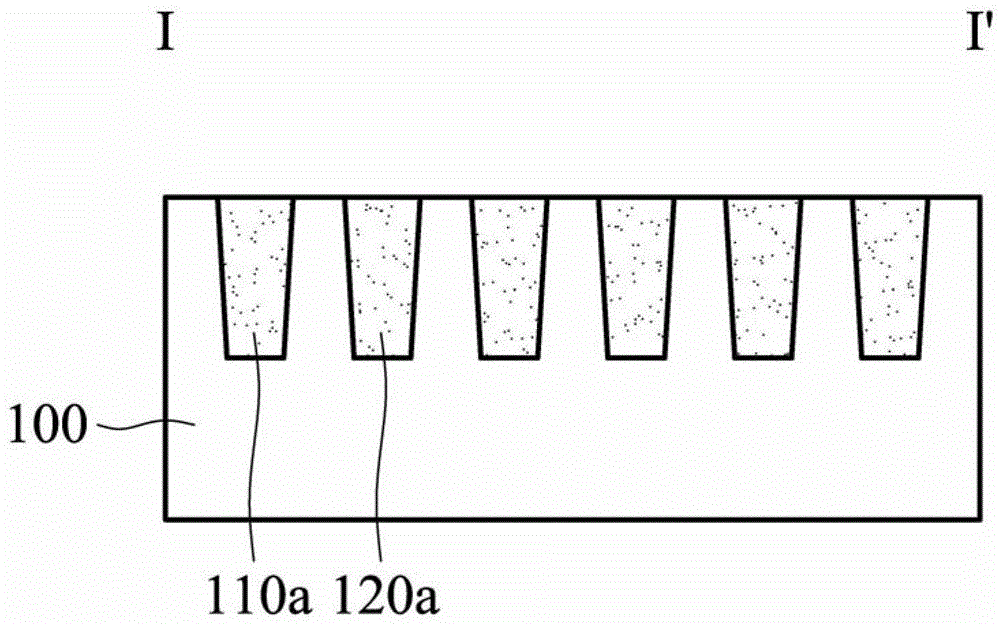

[0027] Figure 3A to Figure 3J is a schematic plan view illustrating a manufacturing method of a semiconductor device according to an embodiment of the present invention. Furthermore, Figure 1A to Figure 1J and Figure 2A to Figure 2J , which are respectively plotted corresponding to Figure 3A to Figure 3J Schematic cross-sectional view of the manufacturing method of the semiconductor device along the line I-I' and correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com