Rotatable flange plate

A flange and shell technology, applied in the field of rotatable flanges, can solve the problems of signal interruption, inconvenience in production and life, irregularities, etc., and achieve the effect of convenient installation and convenient fixed installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

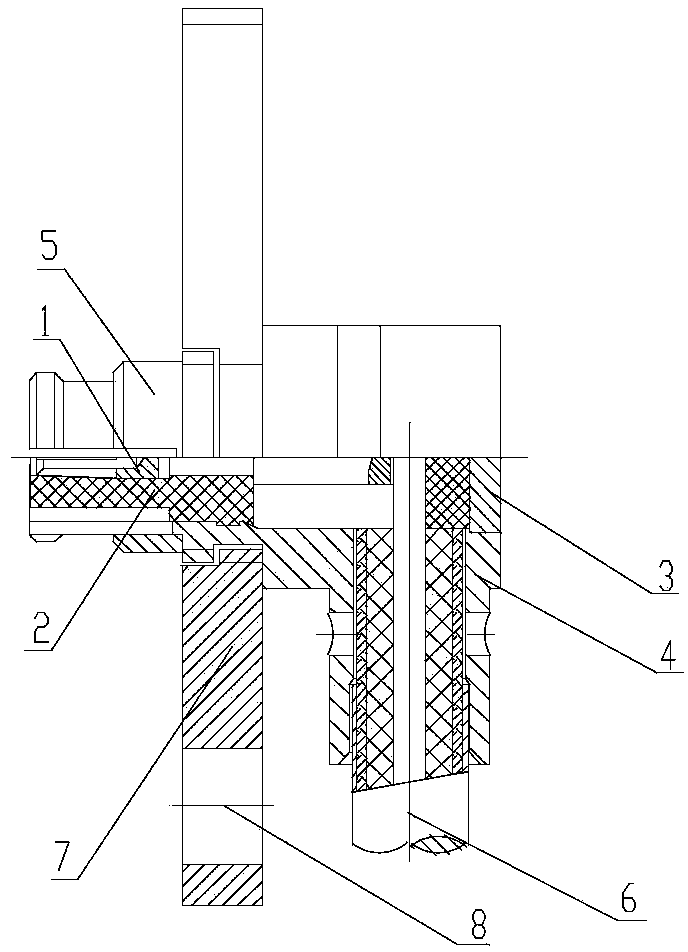

[0011] As shown in the drawings, a rotatable flange of the present invention includes a casing 4 and a flange 7 arranged on the casing 4, a screw is arranged on the casing 4, and a flange 7 is arranged on the casing 4. A screw hole matching the screw on the shell 4 is provided, and the flange 7 and the shell 4 are connected through the screw hole and the screw, so the flange can rotate on the shell. Mounting holes 8 for fixing the flange 7 and connectors are installed at both ends of the flange 7

[0012] A collar 5 is provided on the housing 4 . Rely on the collar 5 to clamp the flange 7 to prevent the flange 7 from unscrewing.

[0013] The assembly method of the present invention is: put the insulator 2 into the shell 4 and press fit it in place, and then press it into the socket 1 to ensure that the slotting direction of the socket is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com