rotary shaver head

A shaver and rotary technology, applied in metal processing and other directions, can solve the problems of inability to shave completely, affect the shaving effect, and difficulty, so as to improve shaving comfort, improve shaving effect, and avoid elastic aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

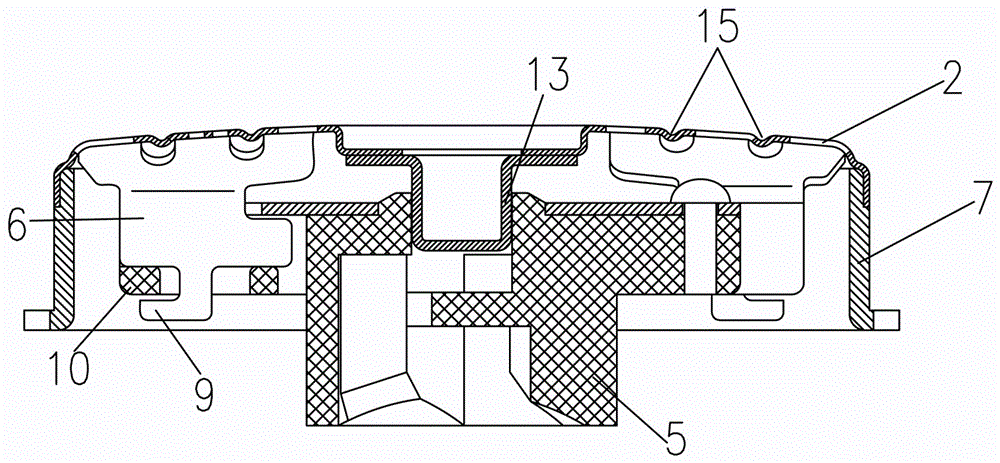

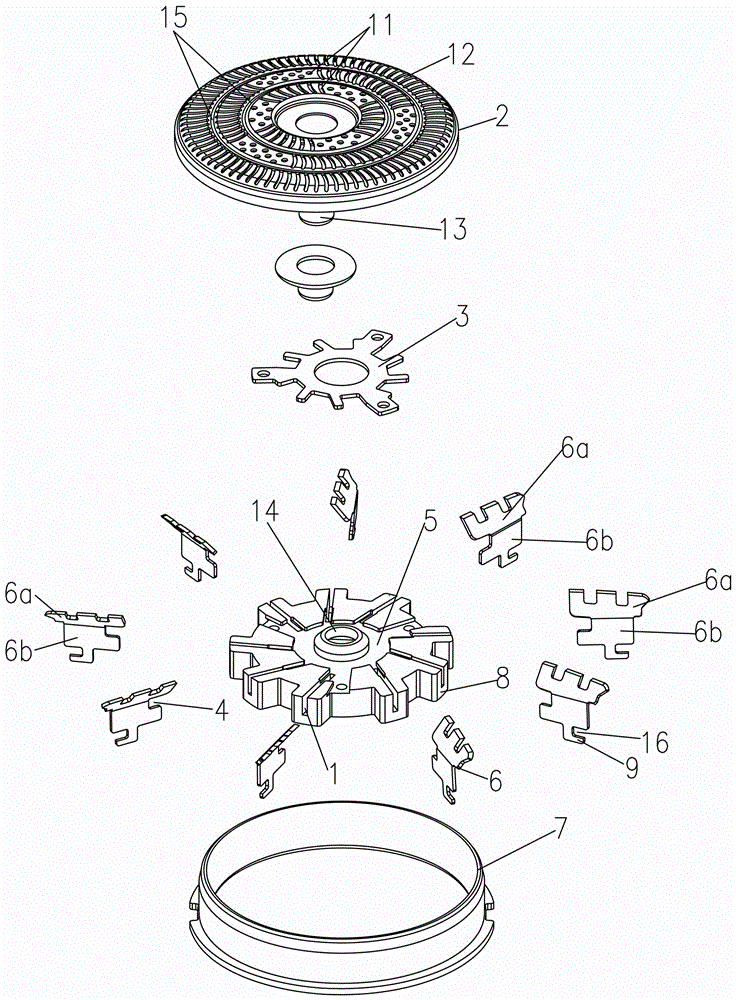

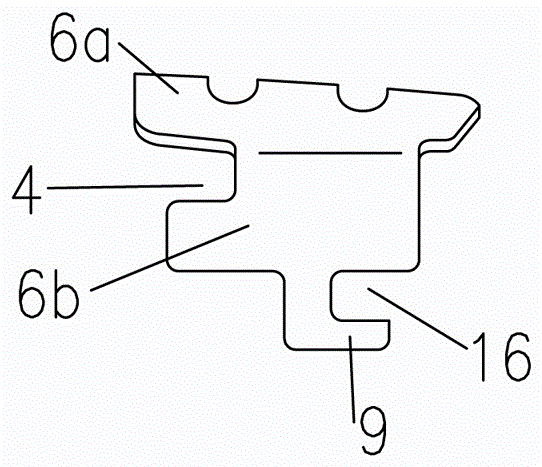

[0018] like figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of specific embodiment of rotary shaver cutter head of the present invention, a kind of rotary shaver cutter head, comprises net cover 2 and a blade plastic frame 5 that rotates relative to net cover 2, blade plastic frame 5 is provided with blade 6. Blade plastic frame 5 and three edge blades 6 are integrally installed in the space that net cover 2 surrounds and forms, and described blade plastic frame 5 comprises the center hole on the center of blade plastic frame 5, the annular evenly distributed blade mounting seat 8, described The central hole 14 cooperates with the fixed axis of rotation of the net cover 2, so that the plastic blade holder 5 rotates around the fixed axis of rotation 13. The blade mounting seat 8 is provided with a mounting groove 1 for mounting the blade 6 , the mounting groove 1 has an upward and outward outlet, and a block 10 is provided at the bottom of the mounting groove 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com