How to detect battery failure

A detection method and battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of shortening the service life of the battery, worsening performance, and short battery life, and achieve the effect of saving costs and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

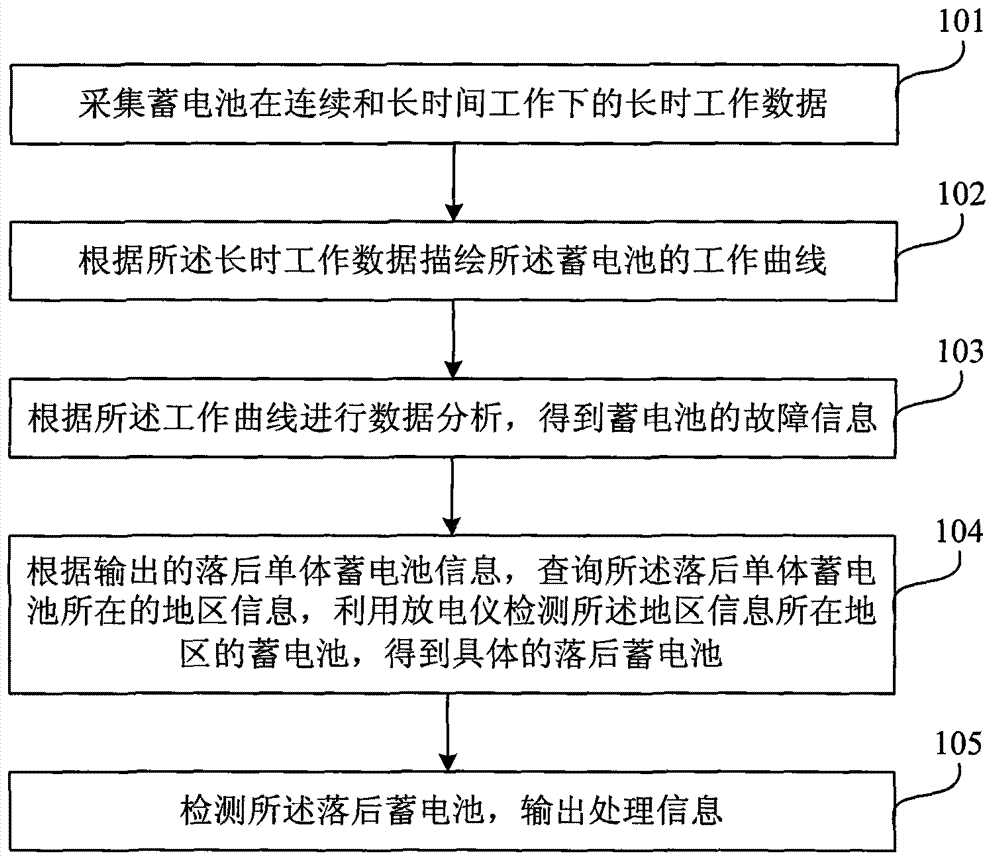

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0012] figure 1 For the detection method of battery failure of the present invention, as shown in the figure, the present invention specifically includes the following steps:

[0013] Step 101, collecting the long-time working data of the storage battery under continuous and long-time work;

[0014] Specifically, the long-time working data of the storage battery under long-time working may be collected at regular time intervals.

[0015] Organize and record the relevant data of the battery to the "data table", including but not limited to: battery brand, network service life, power outage frequency, power outage duration, base station load, appearance, etc.

[0016] Step 102, obtaining the working curve of the storage battery according to the long-term working data;

[0017] After long-term data collection, tracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com