Automatic demolding type replaceable injection mold

A technology of injection molds and molds, which is applied in the field of mold replaceable and automatic mold release injection molds, can solve the problems of inability to use various product shapes, complex injection mold design, inconvenient use, etc., to achieve easy replacement, long service life, The effect of protecting the putter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the drawings.

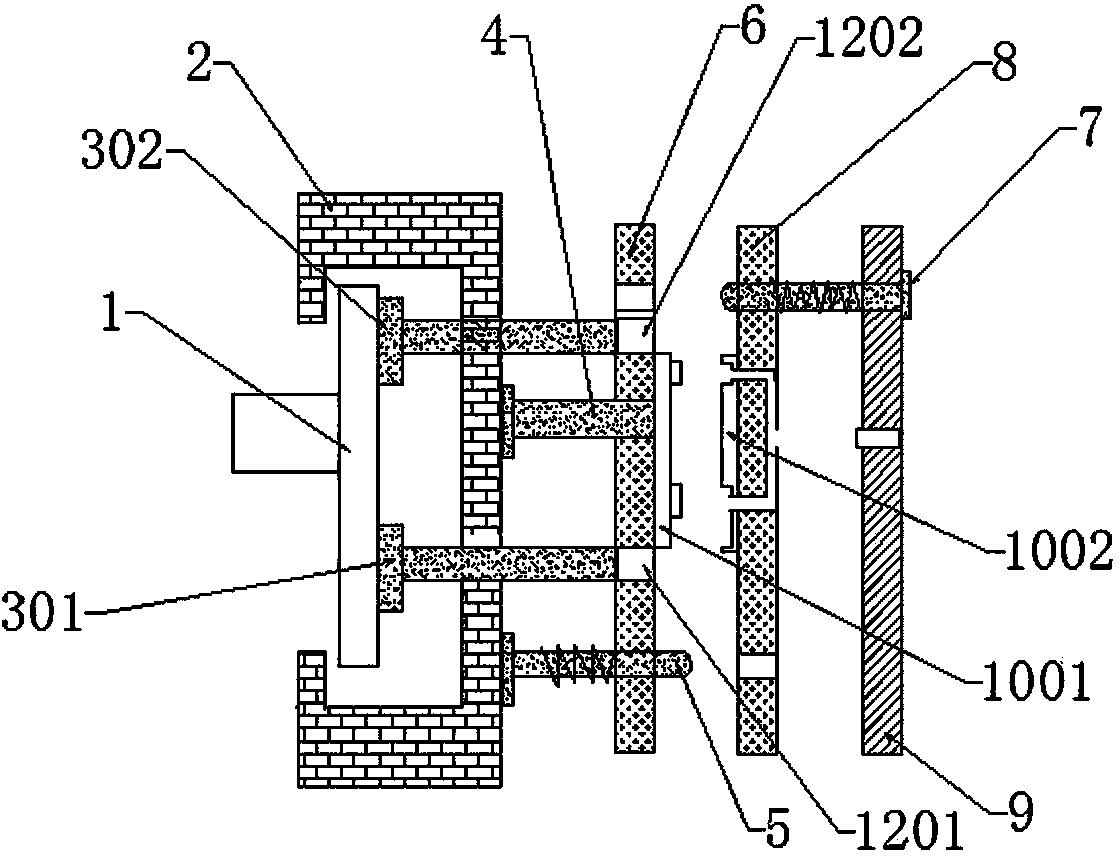

[0026] Such as figure 1 As shown, the mold can be replaced with an automatic demolding injection mold, including a demolding guide rod support 1, a thrust seat 2, a first demolding rod 301, a second demolding rod 302, a push rod 4, a first limit rod 5, The first mold seat 6, the second limiting rod 7, the second mold seat 8 and the gate cover 9.

[0027] The sprue sleeve 9 is provided with a sprue sleeve hole, and the second mold base 8 is provided with a flow glue inlet hole opposite to the sprue sleeve hole.

[0028] The thrust surface of the demolding guide rod support 1 and the thrust surface of the thrust seat 2 are arranged in parallel, the first mold seat 6 is provided with a first demolding through hole 1201, a second demolding through hole 1202, and a first demolding rod 301 , One end of the second demolding rod 302 is fixedly connected to the demolding guide rod support 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com