Self-adaptive leveling method and device of hydraulic support top beam

A hydraulic support, self-adaptive technology, applied in mine roof support, earth square drilling, mining equipment, etc., can solve the problems of unable to realize self-adaptive leveling, unable to realize automatic control well, unable to realize automatic leveling, etc. To achieve the effect of automatic leveling control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

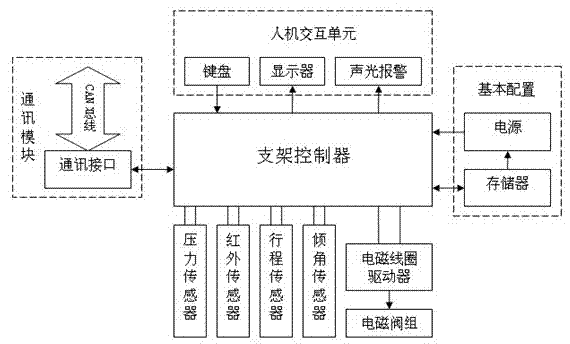

[0026] The method for self-adaptive leveling of the top beam of the hydraulic support includes a main program for self-adaptive leveling of the electro-hydraulic control system of the hydraulic support and a subroutine for self-adaptive leveling of a balance jack;

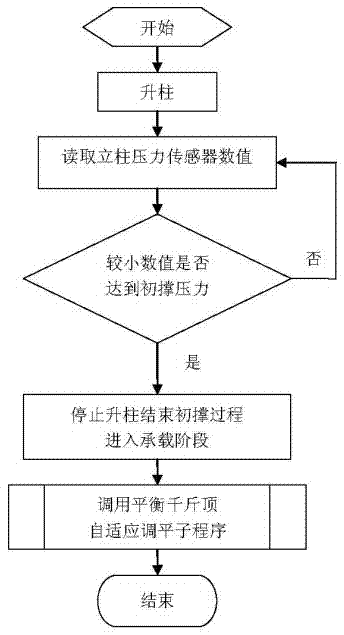

[0027] Such as figure 1 As shown, the working steps of the self-adaptive leveling main program of the hydraulic support electro-hydraulic control system are:

[0028] 1) Start to raise the column;

[0029] 2) Read the value of the column pressure sensor, compare the value, and save the smaller value;

[0030] 3) Judging whether the smaller value reaches the initial support pressure, if it is reached, stop the initial support, and enter the loading stage to continue to step 4; if it does not reach the initial support pressure, return to step 2;

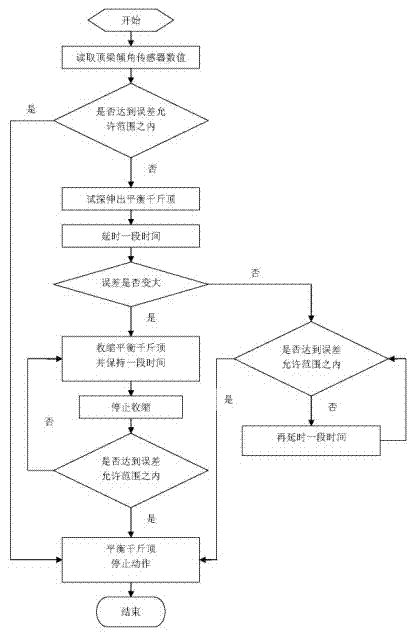

[0031] 4) Call the self-adaptive leveling subroutine of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com