A distributed leveling controller circuit

A controller, distributed technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of non-functioning, poor scalability, low reliability, etc., to achieve high leveling function accuracy and fast running speed , stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

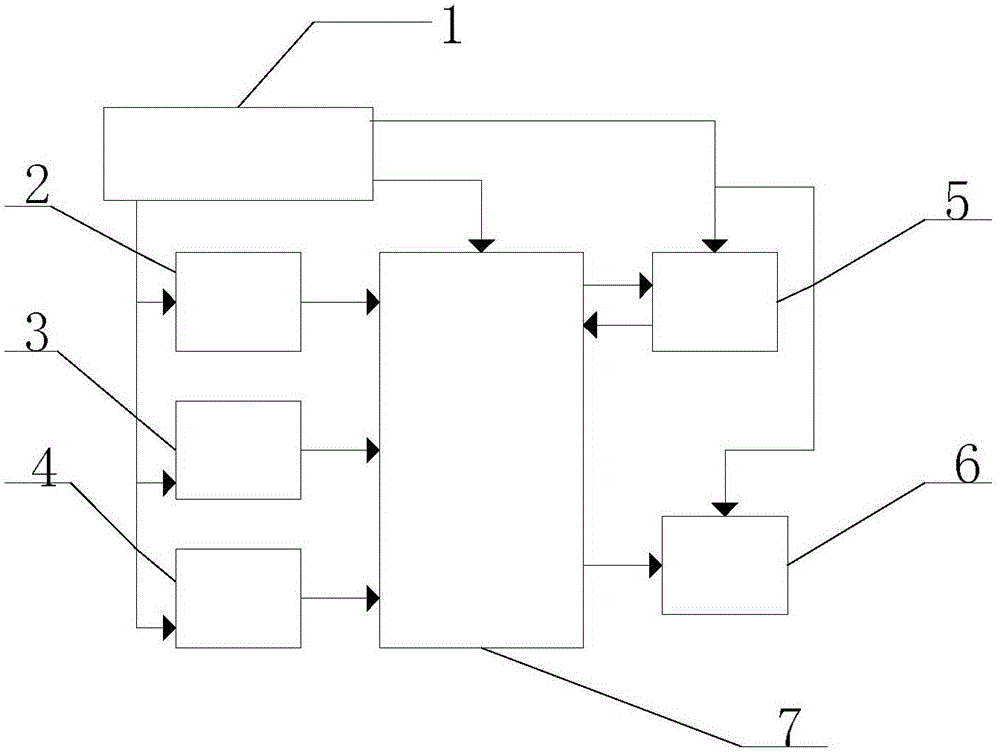

[0022] like figure 1 As shown, the present invention includes a power supply circuit 1, an outrigger ground contact detection circuit 2, an outrigger upper and lower limit detection circuit 3, a two-dimensional inclination angle detection circuit 4, an RS485 bus communication circuit 5, an outrigger control drive circuit 6, a main control The chip circuit 7, the power supply circuit 1 is the outrigger ground contact detection circuit 2, the outrigger upper and lower limit detection circuit 3, the two-dimensional inclination angle detection circuit 4, the RS485 bus communication circuit 5, the outrigger control drive circuit 6, and the main control chip circuit 7 provides 12V voltage and 5V voltage, outrigger ground contact detection circuit 2, outrigger upper and lower limit detection circuit 3, two-dimensional inclination angle detection circuit 4, RS485 bus communication circuit 5, outrigger control drive circuit 6 are all connected with the main control chip Circuit 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com