Compression spring type buffer friction gear meshing clutch

A technology of friction gears and clutches, which is applied in the field of compression spring buffer friction gear meshing clutches, which can solve the problems of difficult separation of gears, wide structure, low power transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

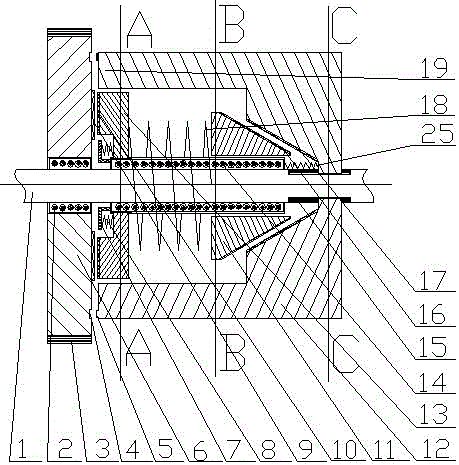

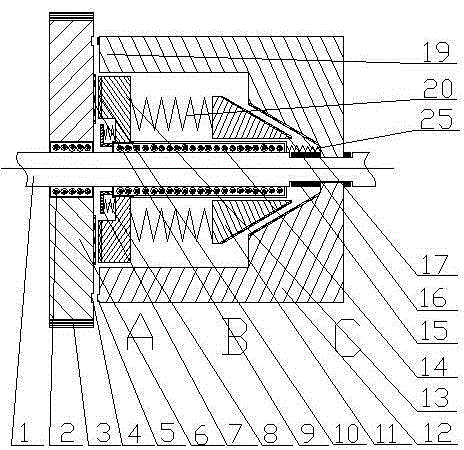

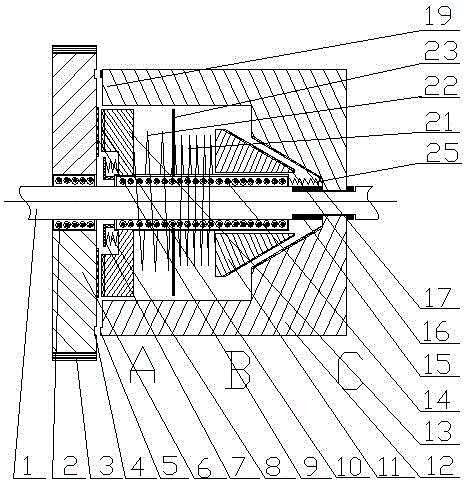

[0026] The driven wheel group comprises a long bearing 14, and a left driven wheel 13 installed on the long bearing 14, a right driven wheel 11, a left driven wheel left spring 8, and a gap between the left driven wheel 13 and the right driven wheel 11 Spring, the spring between the left driven wheel 13 and the right driven wheel 11 has three implementations: Option 1: a large spring 18 is installed between the left driven wheel 13 and the right driven wheel 11, and the large spring 18 is sleeved on the outside of the drive shaft 1 The outer side of the long bearing 14 is not in contact with the outer wall of the long bearing 14, but the central axis of the spring circle of the large spring 18 overlaps with the axis line of the long bearing 14, and the left end of the large spring 18 is fixed on the right side of the left driven wheel 13, and the large spring 18 The right end is fixed on the left side of the right driven wheel 11; Option two: between the left driven wheel 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com