Casing apparatus for an air pump

a technology of casing apparatus and air pump, which is applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of high cost, inconvenient assembly, complex manufacture of casing apparatus, etc., and achieves low cost, secure engagement among the components, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

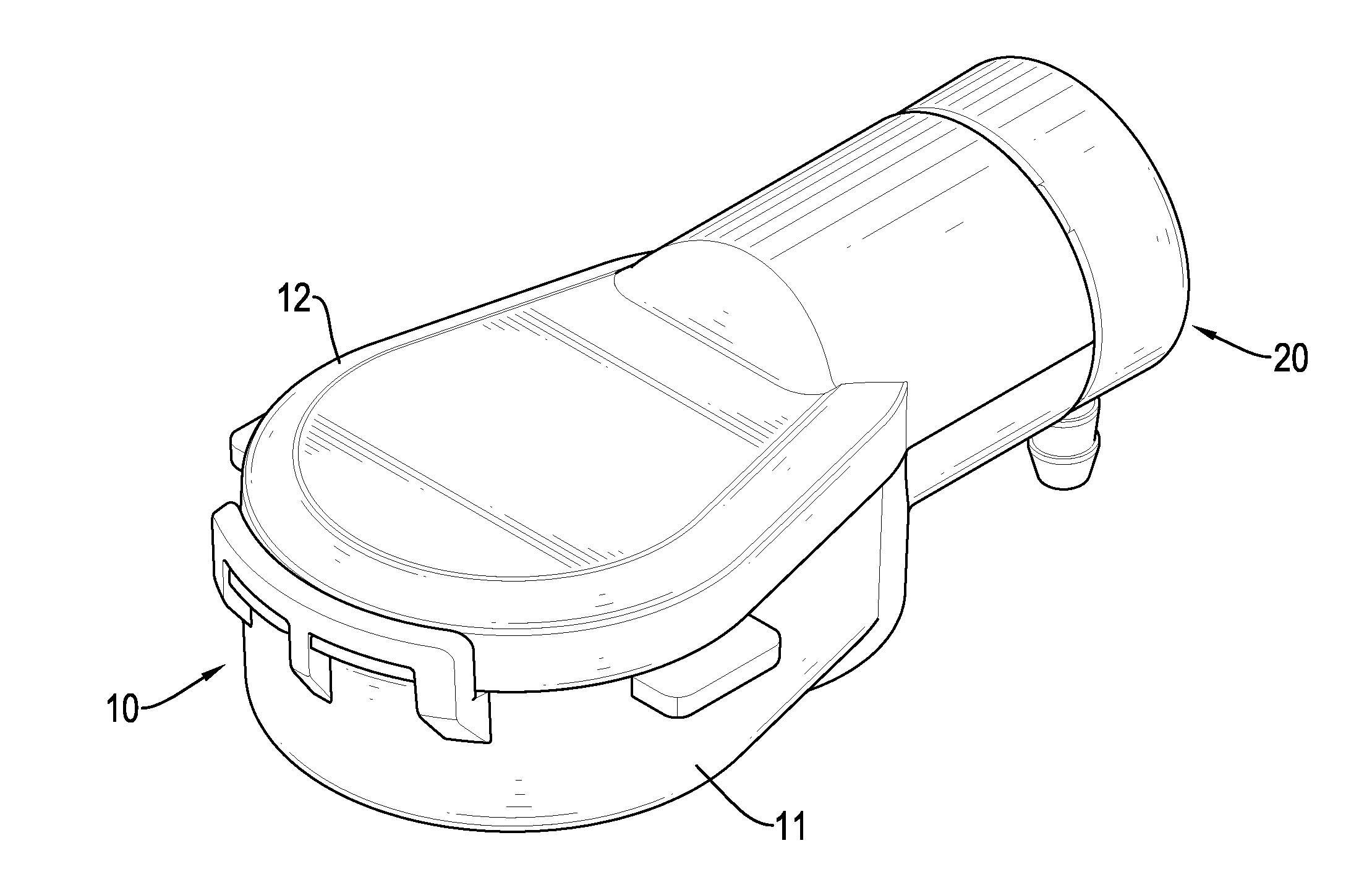

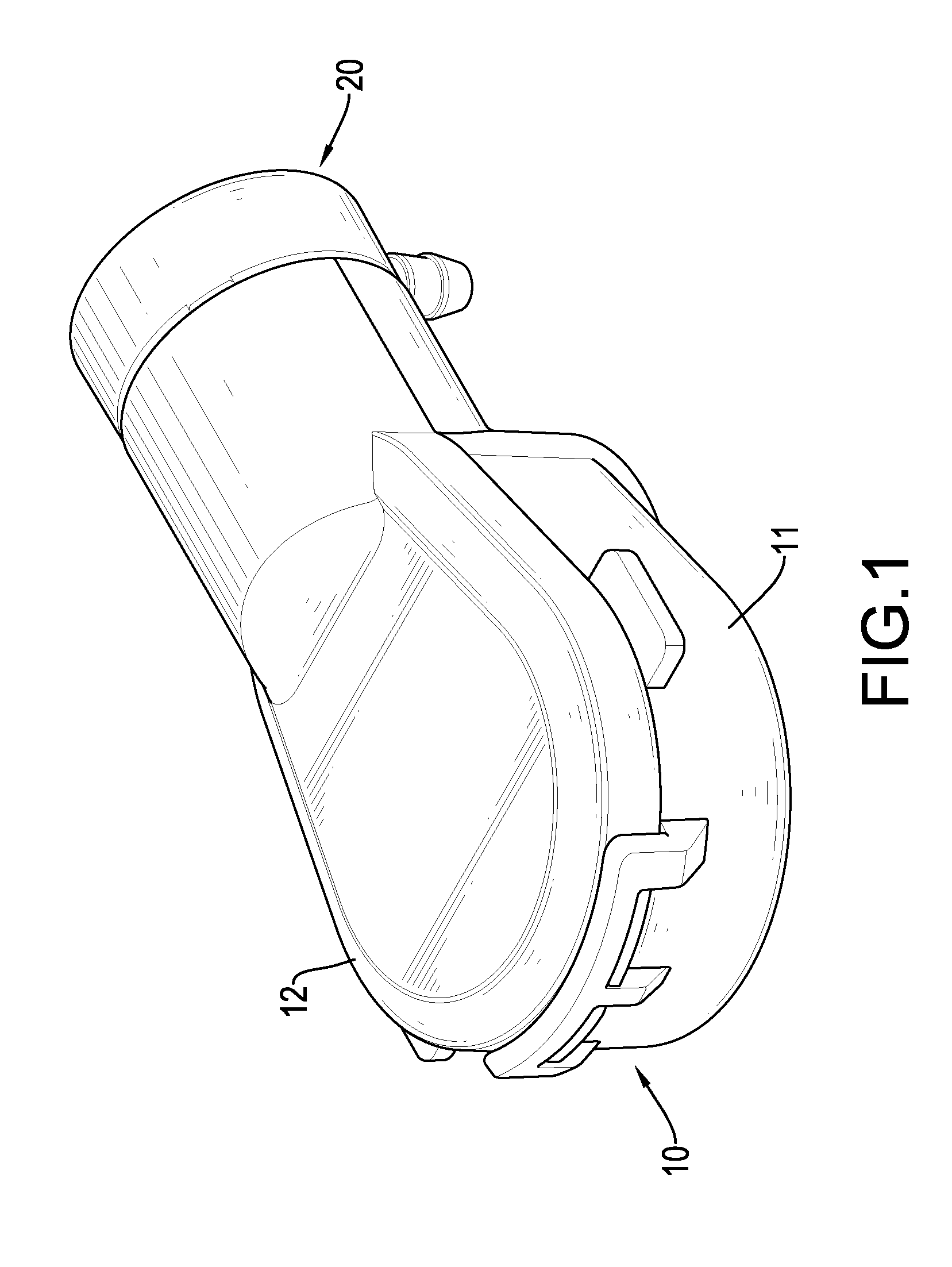

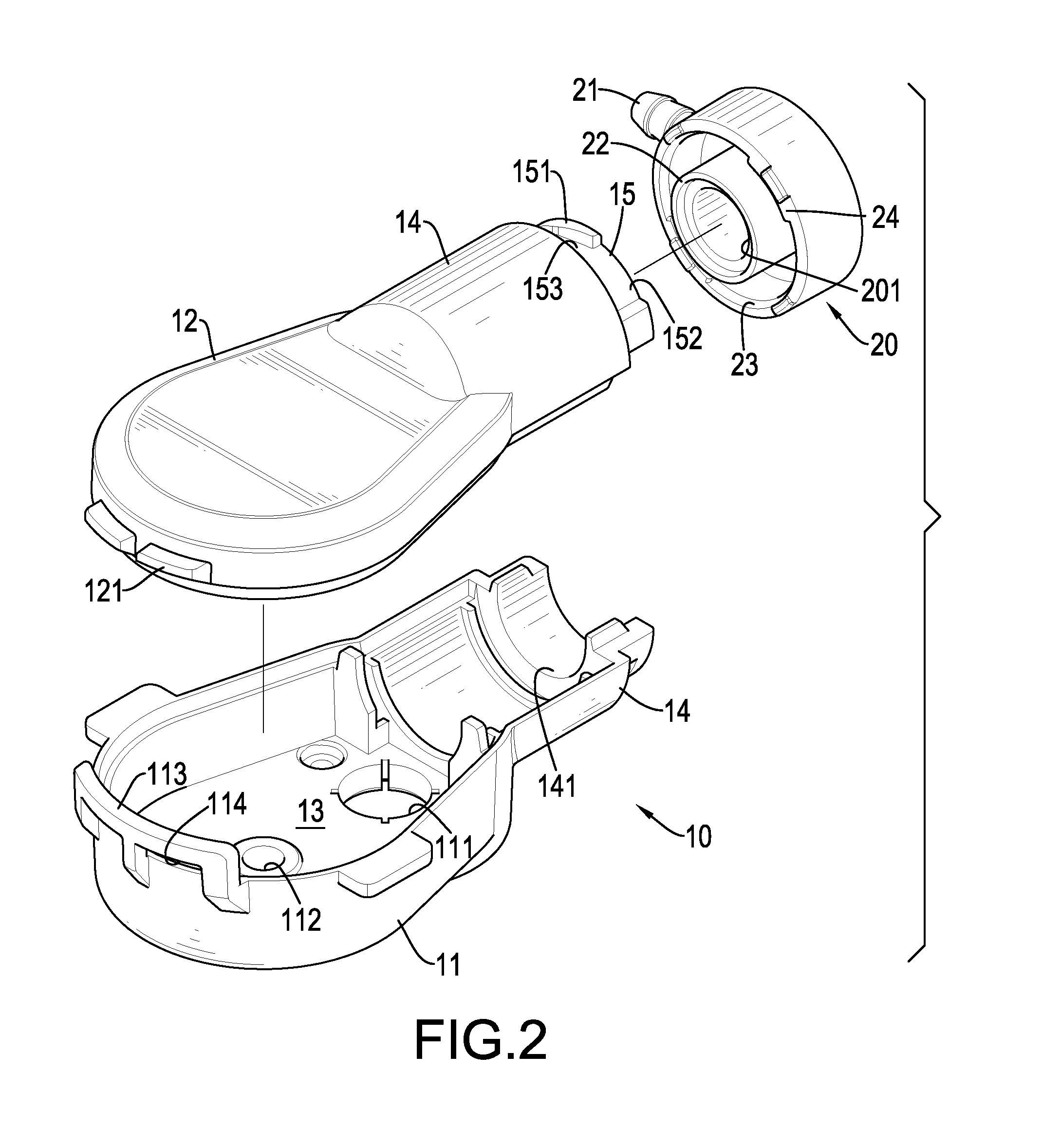

[0020]With reference to FIGS. 1 to 4, a casing apparatus for an air pump in accordance with the present invention comprises a body 10 and a cap 20.

[0021]With reference to FIGS. 1 and 2, the body 10 has a housing, a sleeve portion 14 and a combined portion 15. The housing is composed of a first semi-housing 11 and a second semi-housing 12. A chamber 13 is defined between the first semi-housing 11 and the second semi-housing 12. A driving assembly is mounted on the casing apparatus and protrudes into the chamber 13 of the housing. The sleeve portion 14 is a hollow cylinder and is formed on and axially protrudes from a front end of the housing. The sleeve portion 14 has an air outlet 141 defined through the sleeve portion 14 and in communication with the chamber. The combined portion 15 is axially formed on and protrudes from a front end of the sleeve portion 14. The combined portion 15 has an outer surface, multiple engaging blocks 151, multiple engaging recesses 153 and multiple notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com