Excavator bucket material dynamic weighing device and method

A dynamic weighing and excavator technology, applied to measuring devices, earth movers/shovels, weighing, etc., can solve the problems of reduced excavator excavation efficiency, waste of financial resources, waste of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

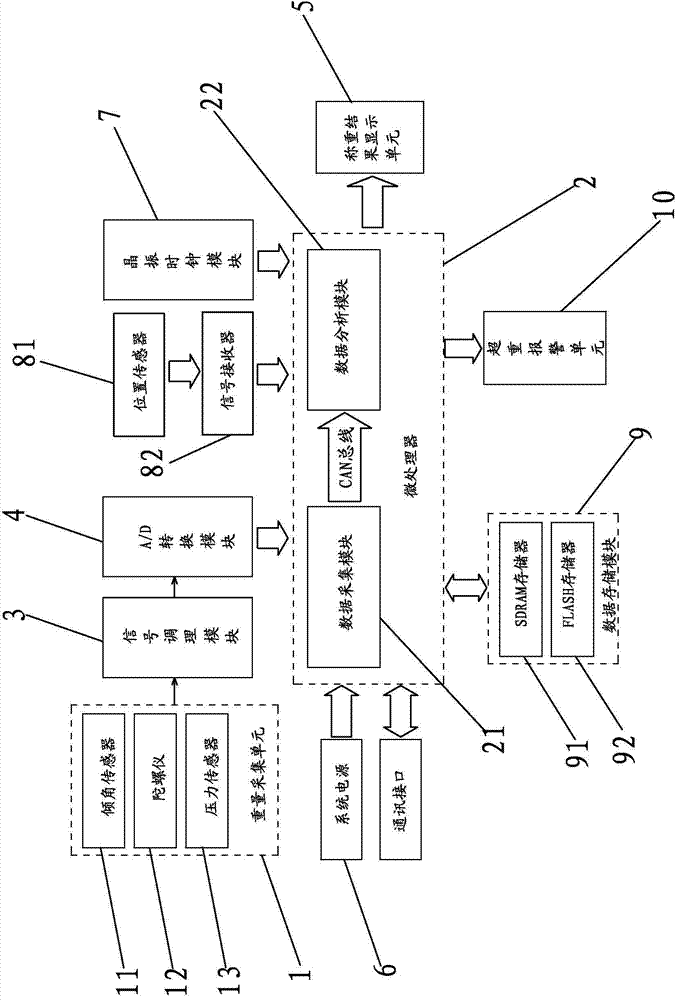

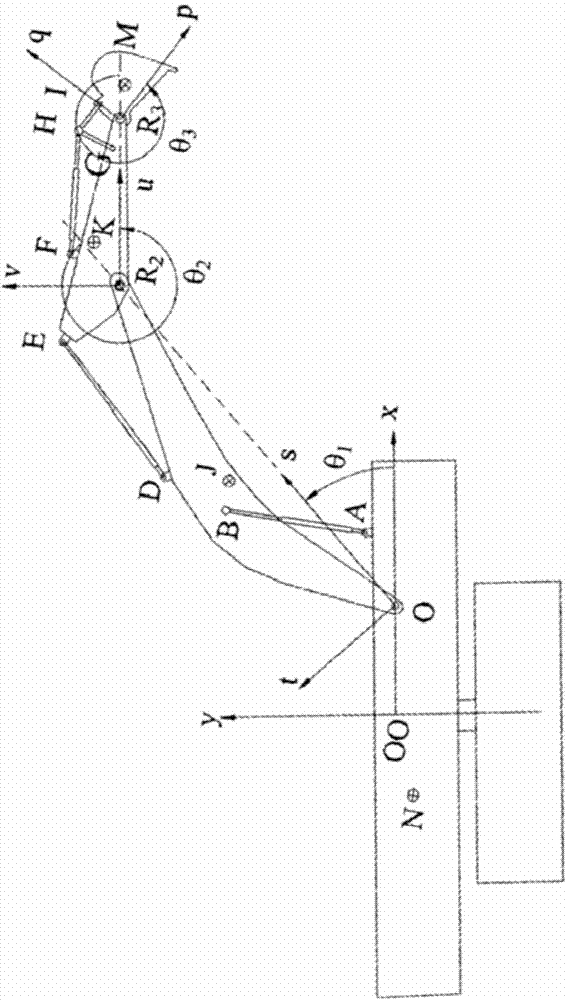

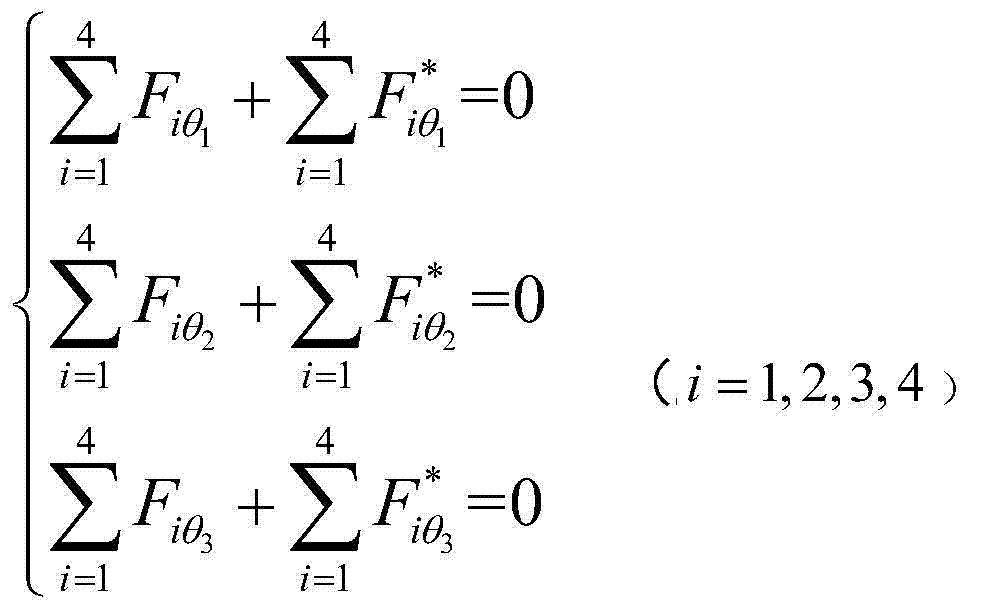

[0056] A dynamic weighing device for excavator bucket materials of the present invention, such as figure 1 As shown, it includes a weight acquisition unit 1, a microprocessor 2, a signal conditioning module 3, an A / D conversion module 4, a weighing display unit 5, a power supply 6 and a crystal oscillator clock module 7. The weight acquisition unit 1 includes an inclination sensor 11 , Gyroscope 12 and pressure sensor 13, there are six pressure sensors 13, and the six pressure sensors 13 are respectively installed in the front and rear chambers of the boom cylinder of the excavator, the front and rear chambers of the bucket lever cylinder of the excavator and the bucket of the excavator In the front and rear chambers of the oil cylinder, the tilt sensor 11 and the gyroscope 12 are installed on the boom, bucket a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com