Plastic joint cutting machine

A cutting machine and plastic technology, applied in metal processing and other directions, can solve the problems of time-consuming and labor-intensive, and achieve the effects of easy operation, low machine cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

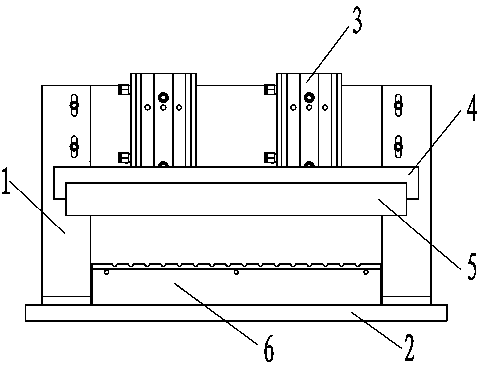

[0011] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0012] A plastic joint cutting machine, including a bracket 1 and a base 2, wherein the bracket 1 is installed on the base 2, and a cylinder 3 is installed on the bracket 1, and the piston on the cylinder 3 passes through a slide rail 4 and a cutter 5 Connected, the base 2 is equipped with a lower pad 6 .

[0013] Further, the number of the cylinders 3 is at least two. Multiple cylinders are fixed on the bracket evenly, and act on the slide rail to make the force more uniform, and can effectively and neatly cut the joint.

[0014] Further, the lower cushion block 6 is arranged directly below the cutter 5, and the joint is cut off by the pressing action of the cutter 5 and the lower cushion block 6 when the cutter 5 is pressed down.

[0015] When the present invention is actually used, the injection molded part to be cut is placed on the lower pad 6, the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com