Mine-used large-span adaptive traction self-moving belt loader

A belt transfer machine, self-adaptive technology, applied in slitting machinery, earthwork drilling and mining, etc., can solve the problem that the transfer machine cannot meet the requirements of high-efficiency and rapid excavation, and achieve the reduction of belt extension frequency, reduction of deformation, and large lap length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

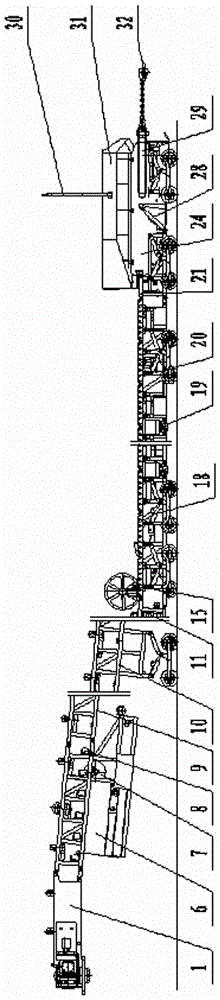

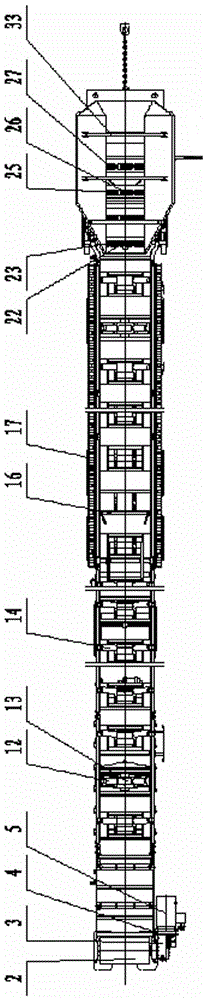

[0038]The specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

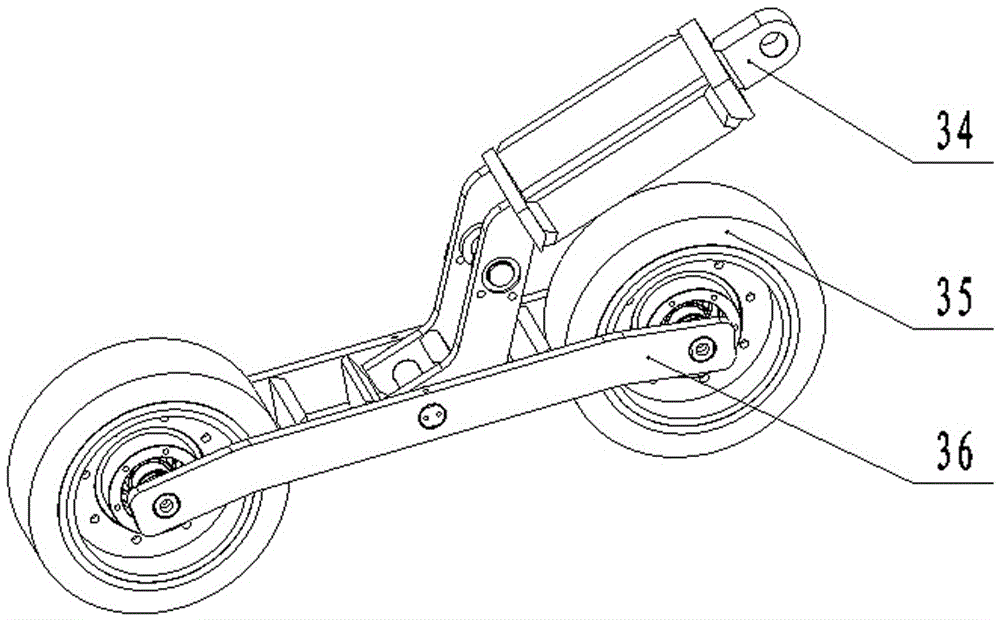

[0039] The mine-used large-span adaptive traction self-moving belt transfer machine of the present invention is an efficient and fast excavation-supported transport equipment, closely following the bolter or full-section excavation machine, and transferring the materials cut by the excavation equipment to the On the grooved belt, it can realize the continuous follow-up operation of the excavation equipment when the bolter is fixed in place for operation. The mine-used traction self-moving loader can be driven forward or backward by the pin tooth drive mechanism of the eight-arm bolter straddling it, and the unloading part is raised by an inclined section and then connected to the tail of the crawler-type self-moving machine .

[0040] The invention is mainly composed of unloading section, inclined section, flat section, loading section, suspension suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com