A kind of automatic welding polishing device and method

A technology of automatic welding and polishing device, applied in the field of machinery, can solve the problems of wasting manpower, reducing operation efficiency, wasting time, etc., and achieving the effect of saving manpower and material resources and achieving a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0028] plan 1:

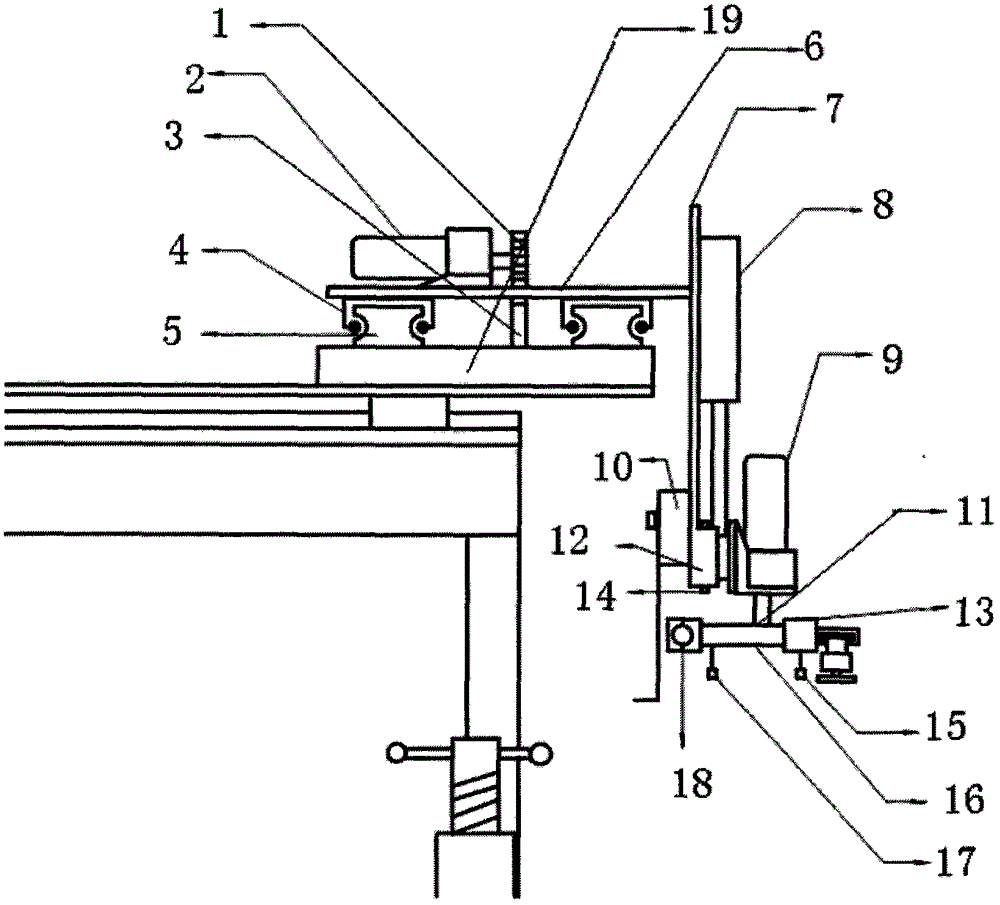

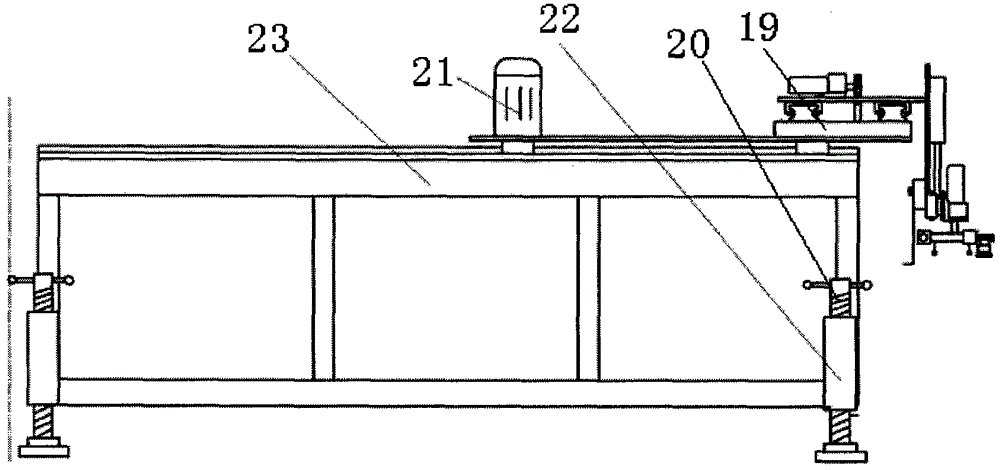

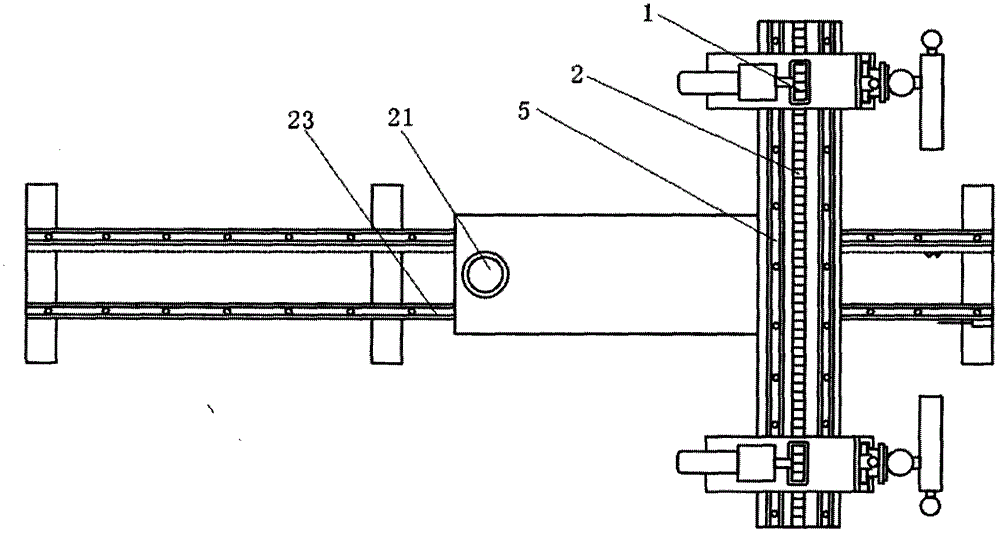

[0029] to combine Figure 1-Figure 6

[0030] An automatic welding and polishing device, which is characterized in that it includes a working part, the working part is installed on a mounting plate 6, and there is a gear 1 on the mounting plate, which engages with a rack 3, and the rack 3 is installed on the base plate 19, the base plate 19 is installed on one side of the traversing track 23 and is located on the plate-shaped structure. There is a rack inside the side of the traversing track 23, and also includes a gear meshed with the rack. The gear is installed On the vertical gear shaft, there is a motion motor 21 above the vertical gear shaft. The vertical gear shaft is located below the plate-like structure and can drive it to move together. On the traversing track 23 and can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com