Automatic welding machine for guide tube of oil level gauge of oil pan

An automatic welding machine and oil pan technology, which is applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve problems such as oil leakage, oil pan shell wall cracking, and lack of vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

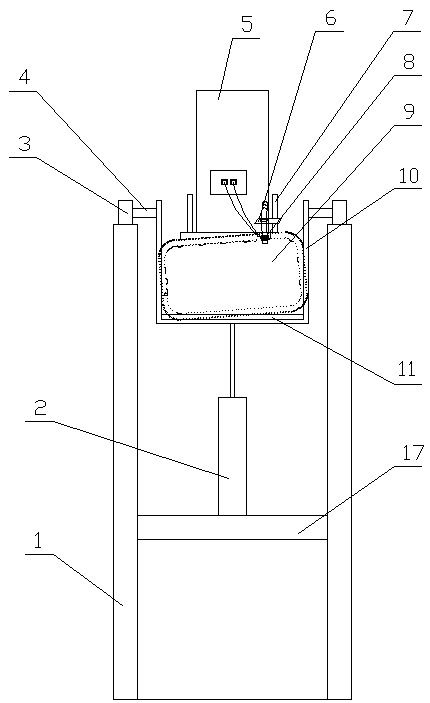

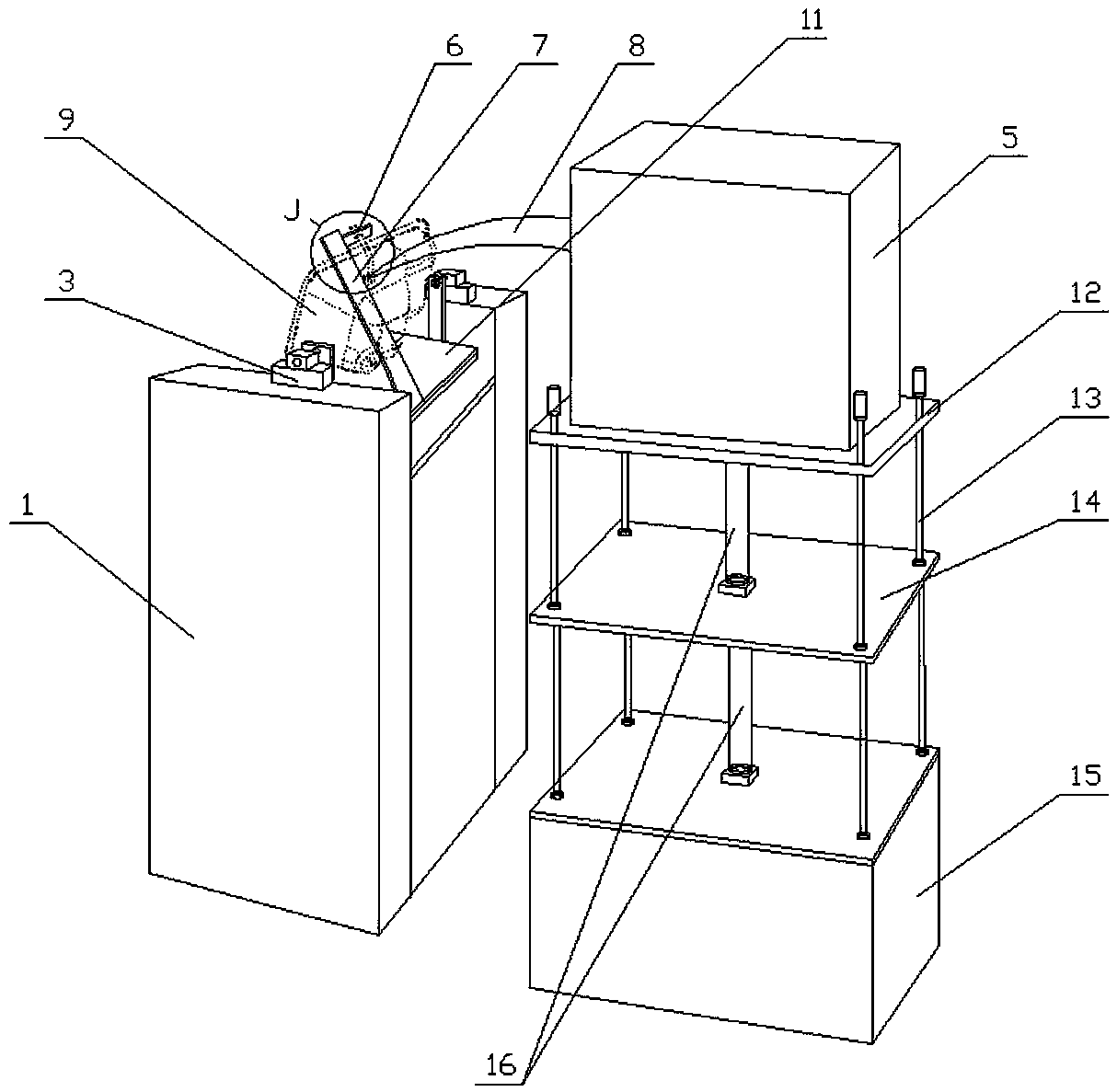

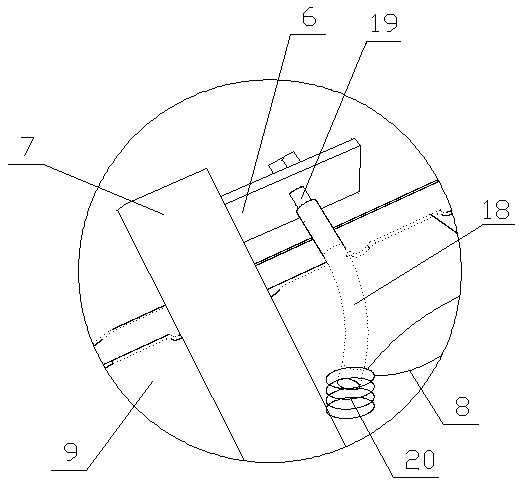

[0013] like figure 1 , figure 2 and image 3 As shown, the automatic welding machine for the oil pan oil dipstick conduit of the present invention includes a frame, and the frame includes two first columns 1 of equal height, and pin seats 3 are arranged on the upper ends of the two first columns 1 . A bracket 10 is arranged between the two pin seats 3 . Described bracket 10 is U-shaped, and pin shaft 4 is all arranged between its two ends and corresponding pin seat 3, and one end of pin shaft 4 is connected with the corresponding end of U-shaped bracket 10, and the other end of pin seat 3 is rotatable and stretches into corresponding Inside the pin seat 3, the U-shaped bracket 10 can rotate around the pin shaft 4 by an angle. The bottom of the support 10 is fixed with a support plate 11, the plate surface of the support plate is perpendicular to the two vertical arms of the U-shaped support 10. One cylinder 2. A cross brace 17 is connected between the adjacent lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com