Automatic infrared ray locating welding machine

An automatic positioning and infrared technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable industrial production, unreasonable welding, and large number of employees, so as to reduce quality risks and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

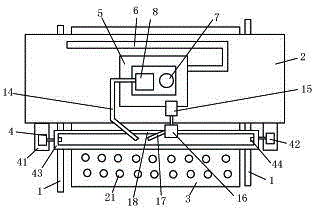

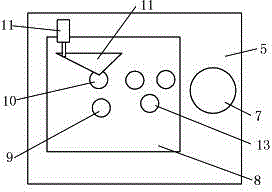

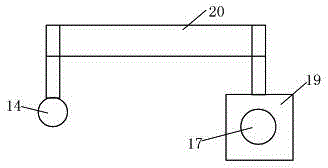

[0014] Combine below Figure 1 to Figure 3 Specific description embodiment:

[0015] Such as Figure 1 to Figure 3 , an infrared automatic positioning welding machine, including a first slide rail 1, a slide seat 2 is slidably provided on the first slide rail, and a welding material frame 3 is provided under the slide seat 2, and the slide seat 2 The side is provided with an infrared positioning and pressing device 4; the infrared positioning and pressing device 4 includes a base 41 fixedly arranged at both ends of the side of the slide seat 2, the base 41 is provided with a cylinder 42, and the output of the cylinder 42 The ends are connected at the two ends of the back-shaped pressing frame 43, and the back-shaped pressing frame 43 can approach the welding material frame 3 for pressing under the action of the cylinder 42. The two ends of the back-shaped pressing frame 43 are provided with Infrared device 44; said slide 2 is provided with a welding car 5, and the welding ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com