Automatic welding system for header welding

An automatic welding and header technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of many subjective factors and heavy workload in manual operation, so as to reduce manpower, improve welding quality, reduce The effect of many subjective factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

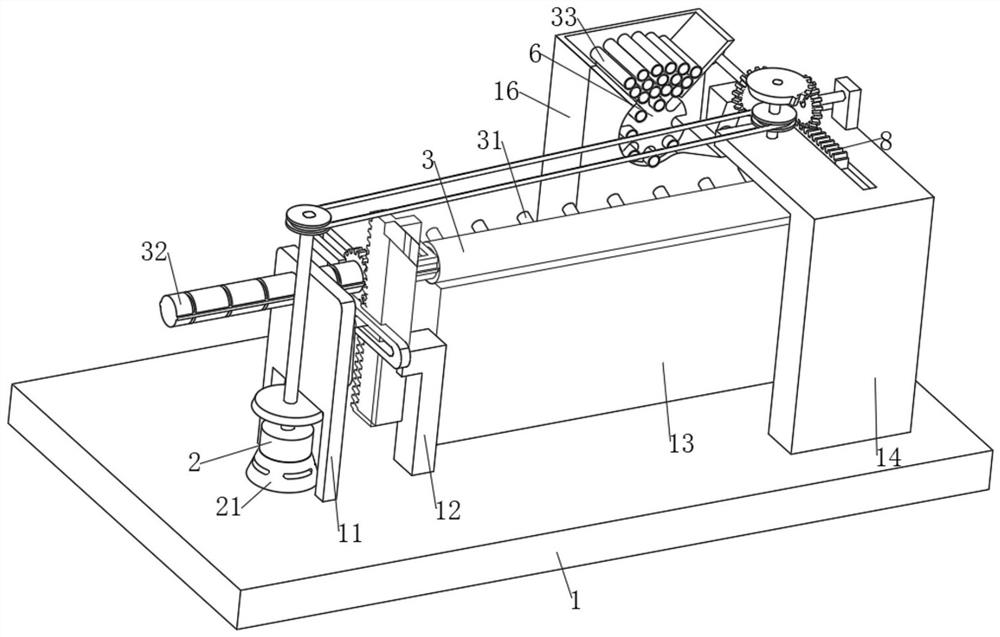

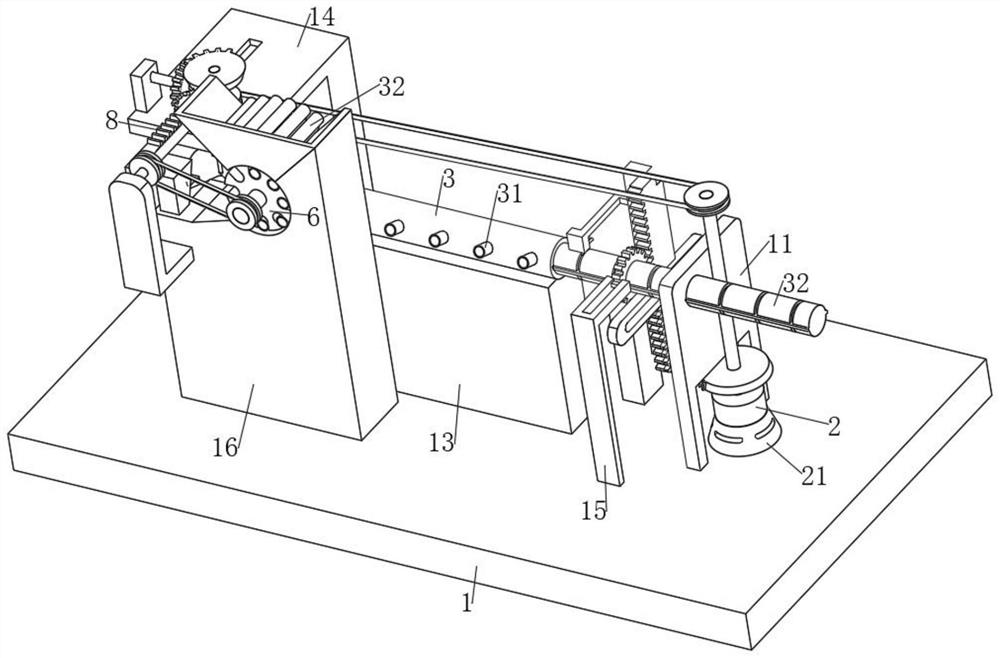

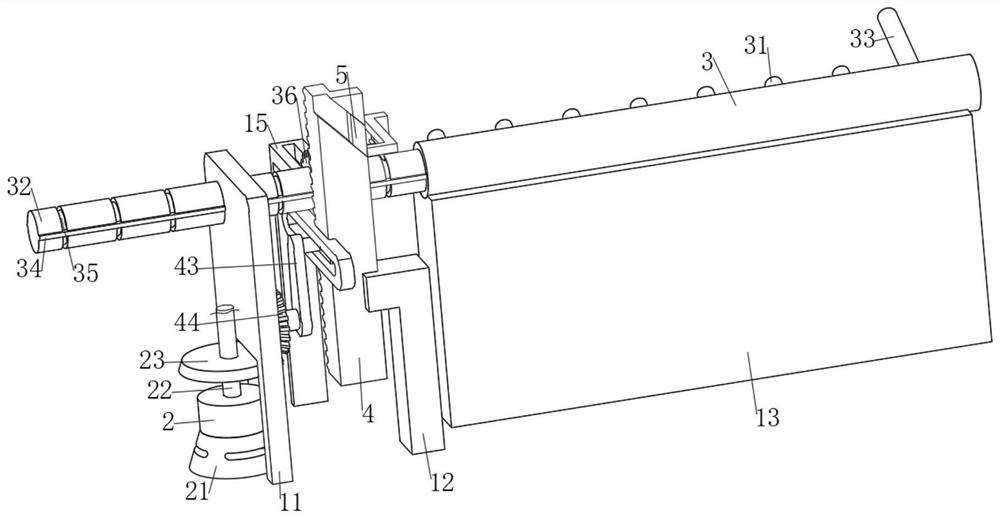

[0031] The present invention provides a technical solution: an automatic welding system for header welding, including a load-bearing plate 1 and a welding torch 7, the upper surface of the load-bearing plate 1 is fixedly connected with a first support plate 13 for supporting the total sleeve 3, the first The support plate 13 is provided with a chute for the limited sliding of the total sleeve 3, and the upper surface of the bearing plate 1 is fixedly connected with a first support frame 11, a second support plate 12 and a second support frame 14, and the first support frame 11 It is provided with a rotating mechanism for driving the total sleeve 3 to rotate so that the total sleeve and the rear half of the lower pipe can be welded. The second support plate 12 is provided with a chute and is slidably connected with the first tooth through the chute. Bar 4, the first rack 4 is provided with a pushing mechanism for pushing the total sleeve 3 so as not to be manually pushed, and th...

Embodiment 2

[0044] It is basically the same as the first embodiment, furthermore, the load-bearing plate 1 is provided with a discharge mechanism for intermittently discharging the lower-level pipe 33, the load-bearing plate 1 is fixedly connected with a support block 16, and the support block 16 is fixedly connected with a device for storing the lower-level pipe. 33 of the storage bucket 61, the fixed shaft rotation on the support block 16 is connected with a disc 6, and there are multiple sets of placement grooves for intermittently discharging the lower tube 33 on the disc 6, and the support block 16 is provided with a sliding slot for the lower tube 33. Inclined surface, the support block 16 is provided with a chute for the lower pipe 33 to be sleeved on the support sleeve 31, the disc 6 is coaxially fixedly connected with a third rotating rod 62, and the third rotating rod 62 is fixedly connected with a third rotating rod 62. Disc wheel 63.

[0045] Furthermore, the discharge mechani...

Embodiment 3

[0048] It is basically the same as the second embodiment, furthermore, the second support frame 14 is provided with a fixing mechanism for fixing the lower pipe 33 along the supporting sleeve 31 with the main sleeve 3, and the fixing mechanism includes a fixed connection on the second The third supporting plate 18 on the support frame 14, the fifth rotating rod 81 is connected with fixed axis rotation on the third supporting plate 18, and the arc profile of the fifth rotating rod 81 is fixedly connected with the second incomplete bevel gear 73 The third bevel gear 82 of intermittent meshing, the third support plate 18 is provided with a chute and is slidably connected with the second rack 8 meshing with the third bevel gear 82 through the chute limit, the second rack 8 is A fixed block 83 for fixing the lower pipe 33 along the support sleeve 31 with the main sleeve 3 is fixedly connected, a baffle 85 is fixedly connected to the lower surface of the second rack 8, and a baffle 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com