Barbecue grill steel wire ring welding equipment

A technology for welding equipment and wire rings, which is applied to the field of welding equipment for wire rings of barbecue grills, can solve the problems of difficult quality control and low efficiency, and achieve the effect of saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

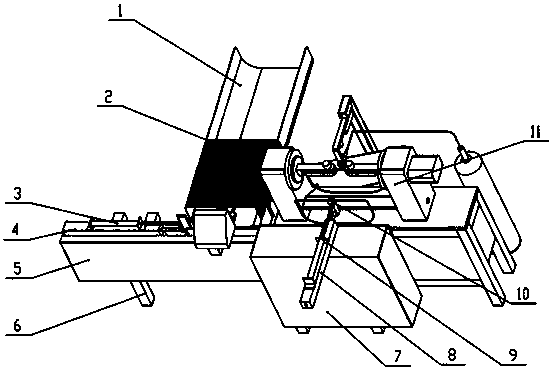

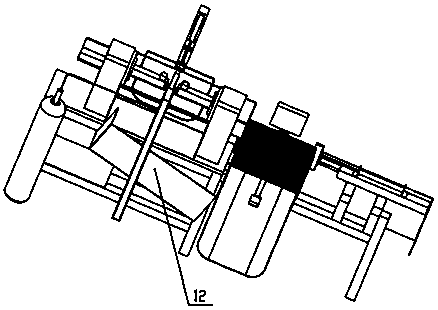

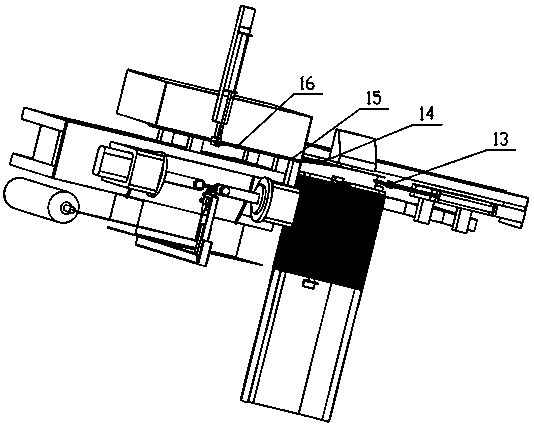

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a barbecue oven traveler welding equipment includes: a sleeve frame mechanism 1, a platform 5, legs 6, a shield 7, a first transportation mechanism, a second transportation mechanism, a welding mechanism, a supporting rotating fixture 11 and a collection box 12;

[0030] The legs 6 are fixedly installed under the platform 5, the welding mechanism and the sleeve frame mechanism 1 are installed on the top, the controller is installed on the side, the traveler 2 is set on the sleeve frame mechanism 1, and the first transportation mechanism is installed on the platform 5. On one side of the frame mechanism 1, the protective cover 7 is fixedly installed on the other side of the platform 5, and the second transportation mechanism is connected with the protective cover 7, and there are two supporting rotating fixtures 11, which are fixedly installed on the platform 5 respectively, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com