Locating mechanism

A technology of positioning mechanism and fixing plate, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high labor intensity, inaccurate positioning of push rods, affecting the quality of pressed products, etc., to ensure the quality and positioning of pressed products. Product accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

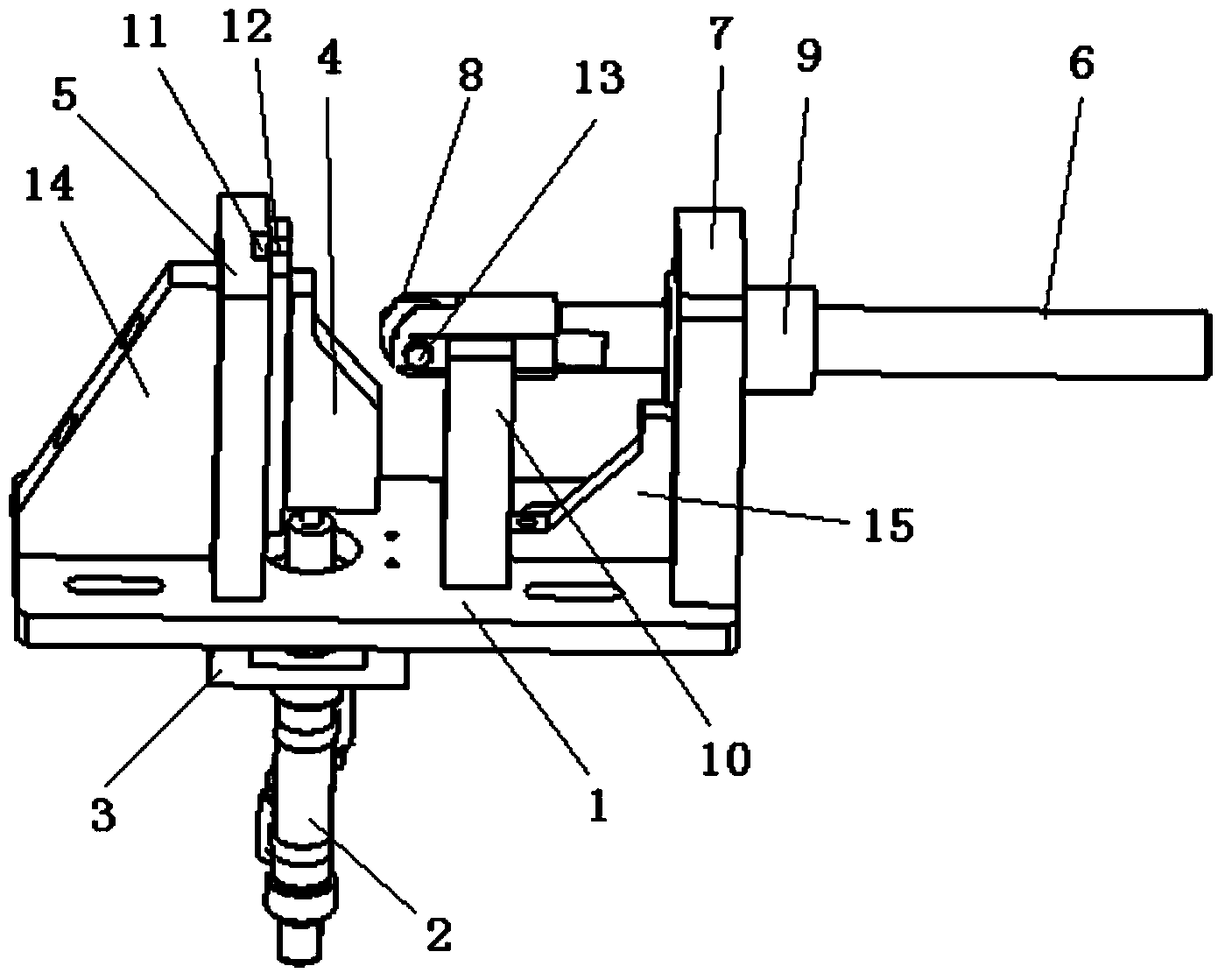

[0013] Examples, see attached figure 1 , a positioning mechanism, which includes a base plate 1, a cam lift cylinder 2, a lift cylinder fixed plate 3, a cam 4, a cam baffle plate 5, a push rod 6, a push rod support plate 7, a roller 8, a linear bearing 9 and a block 10 , the lifting cylinder fixing plate is installed on the bottom of the base plate, and the cam lifting cylinder is installed on the lifting cylinder fixing plate; the lifting rod of the cam lifting cylinder passes through the base plate and is connected with the cam; the base plate is fixedly equipped with a cam stop There is a slide rail 11 on the cam baffle, and a slide plate 12 is provided on the cam. The slide rail and the slide plate are installed together. When the cam lifting cylinder pushes the lifting rod to move up and down, the cam can move up and down along the slide rail to ensure that the cam Stability and direction of movement; the push rod support plate is installed on the base plate, a linear bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com