Method for manufacturing sinter

A production method and technology for sintering ore, applied in the field of mineral sintering, can solve the problems of low TFe grade, fluctuating sintering production, impossible to be too high, generally not more than 5%, etc., and achieve the effect of reducing the cost of ore blending and sintering composition stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

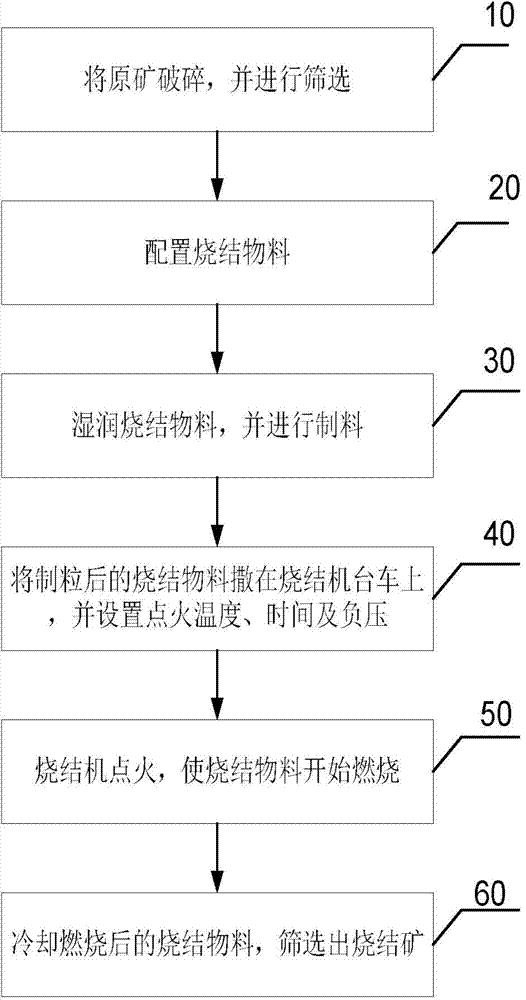

[0013] see figure 1 , the embodiment of the present invention provides a method for making sintered ore, including:

[0014] Step 10: crush the raw ore, and use the first sieve with a sieve hole of 8mm to screen, the undersize is the first raw ore, the oversize is the second raw ore, and the mass ratio of the first raw ore to the second raw ore is 1: 2. The first raw ore is directly used for sintering, and the second raw ore is subjected to flotation and magnetic separation to form fine fine powder, and the particle size is controlled to be -200 mesh fine fine powder not less than 80% of the total mass of fine fine powder. The fine powder is used for sintering.

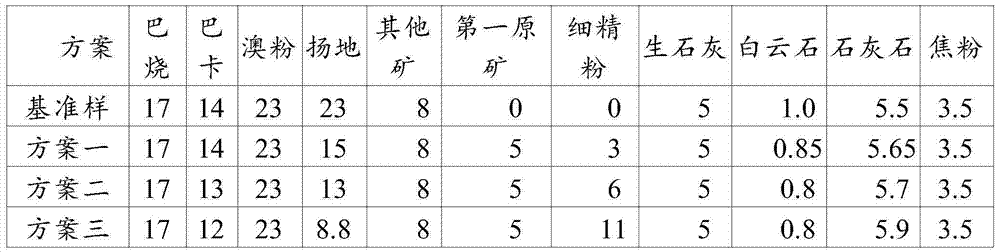

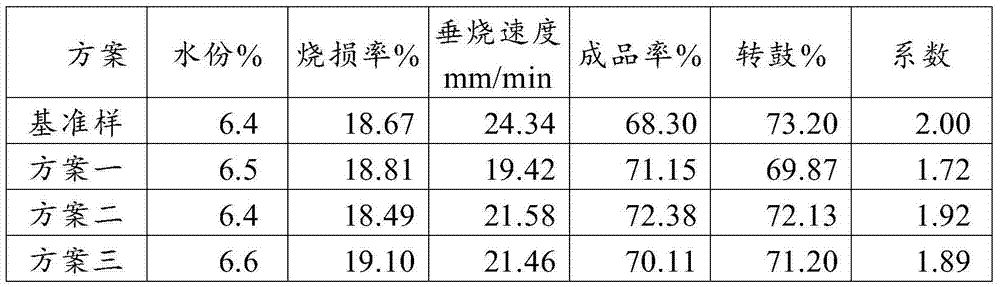

[0015] Step 20: Configure the sintered material, wherein the total proportion of the first raw ore and fine fine powder in the sintered material is 4-20%, the proportion of quicklime is 4.5-5.5%, the proportion of dolomite is 1-3%, and the proportion of limestone 5-7%, coke powder ratio is 3-5%, the ratio mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com