Running control method for fan group at condensing side of refrigeration system

A refrigeration system and operation control technology, applied in the field of control, can solve the problems of burning compressors, difference changes, large changes, etc., and achieve the effect of improving stability and smooth adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

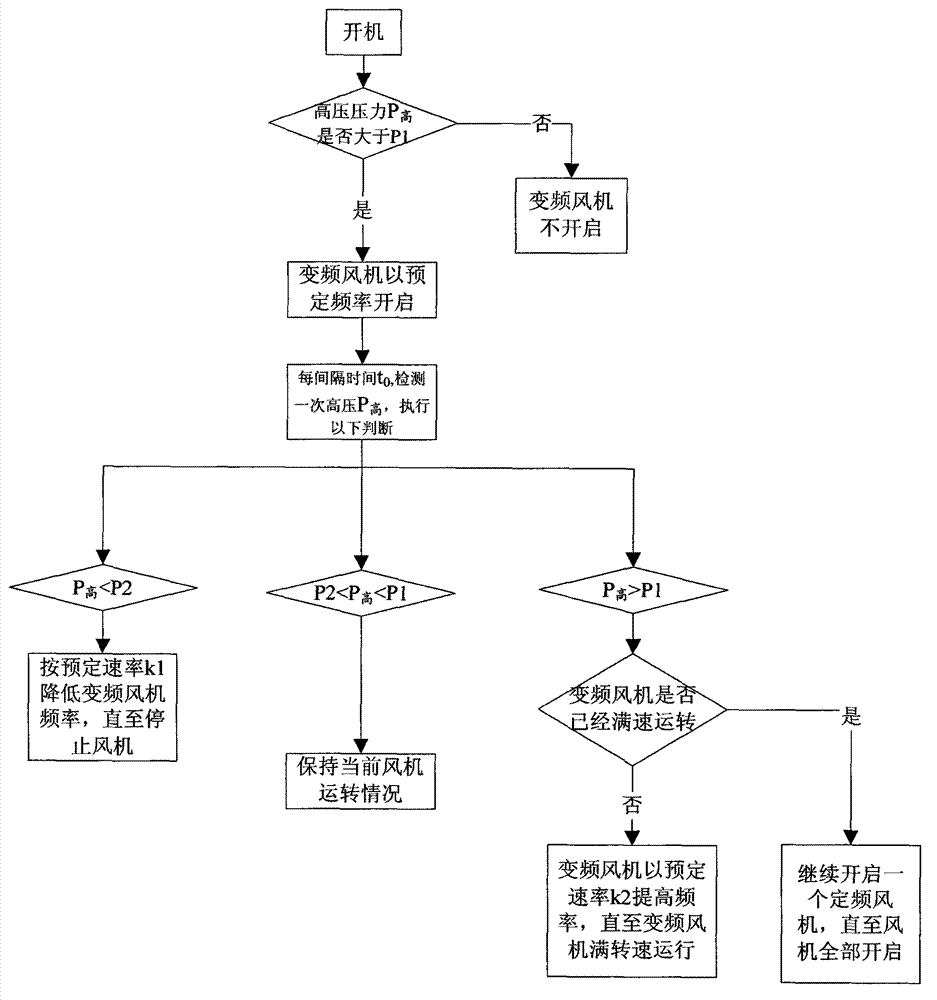

[0014] In the first embodiment of the present invention, taking the screw air-cooled water chiller as an example, the condensation side of the unit adopts an air-cooled heat exchanger, and the condensation side fan unit adopts 1 variable frequency fan and 3 fixed frequency fans.

[0015] Set the high pressure P of the unit 高 The judgment reference value, the first reference value P1 is 14bar, the second reference value P2 is 9bar, the system high pressure protection pressure P 保 is 26bar; set the high pressure P of the unit 高 The detection interval time t 0 The applicant found that increasing the air volume of the condensing side fan unit can reduce the high pressure P of the refrigeration system 高 , reducing the air volume of the condensing side fan unit will increase the high pressure P 高 . In the first embodiment, the specific control method for the condensing side fan unit is as follows:

[0016] S1, start the unit;

[0017] S2. Detect high pressure P 高 , if P 高 >1...

Embodiment 2

[0025] In the second embodiment of the present invention, taking a screw air-cooled water chiller as an example, the condensation side of the unit adopts an air-cooled heat exchanger, and the condensation side fan unit adopts 1 variable-frequency fan and 3 fixed-frequency fans.

[0026] Set the high pressure P of the unit 高 The judgment reference value, the first reference value P1 is 9bar, the second reference value P2 is 14bar, the system high pressure protection pressure P 保 is 26bar; set the high pressure P of the unit 高 The detection interval time t 0 is 10s, the specific control method for the condensing side fan unit is as follows:

[0027] S1, start the unit;

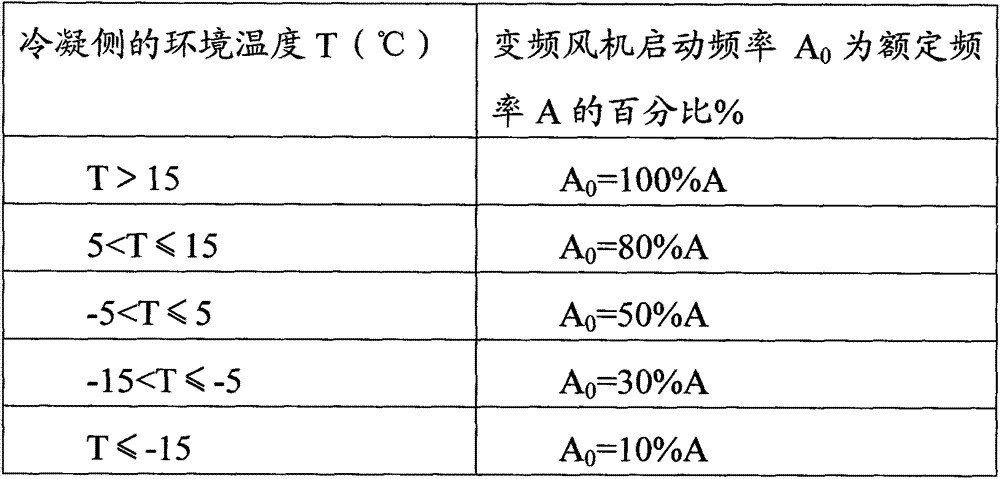

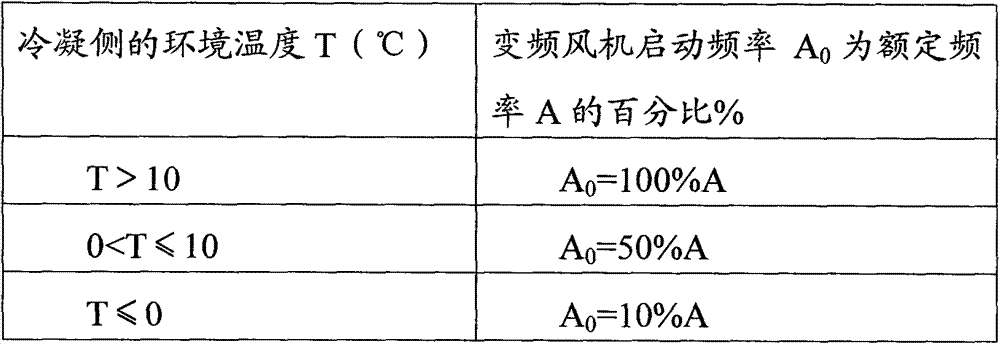

[0028] S2. Detect high pressure P 高 , if P 高 >14bar, then detect the ambient temperature T on the condensing side, and determine the starting frequency A of the variable frequency fan according to the range of the ambient temperature T on the condensing side 0 And start the frequency conversion fan; if P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com