Tank for a motor vehicle, in particular fuel or auxiliary fluid tank for a motor vehicle, and method for producing such a tank

An auxiliary fluid and motor vehicle technology, applied in the direction of arrangement, application, and power device combined with the fuel supply of the internal combustion engine, can solve the problems of damaged latch connection form-fit connection, inability to operate the chassis, etc., and achieve the effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

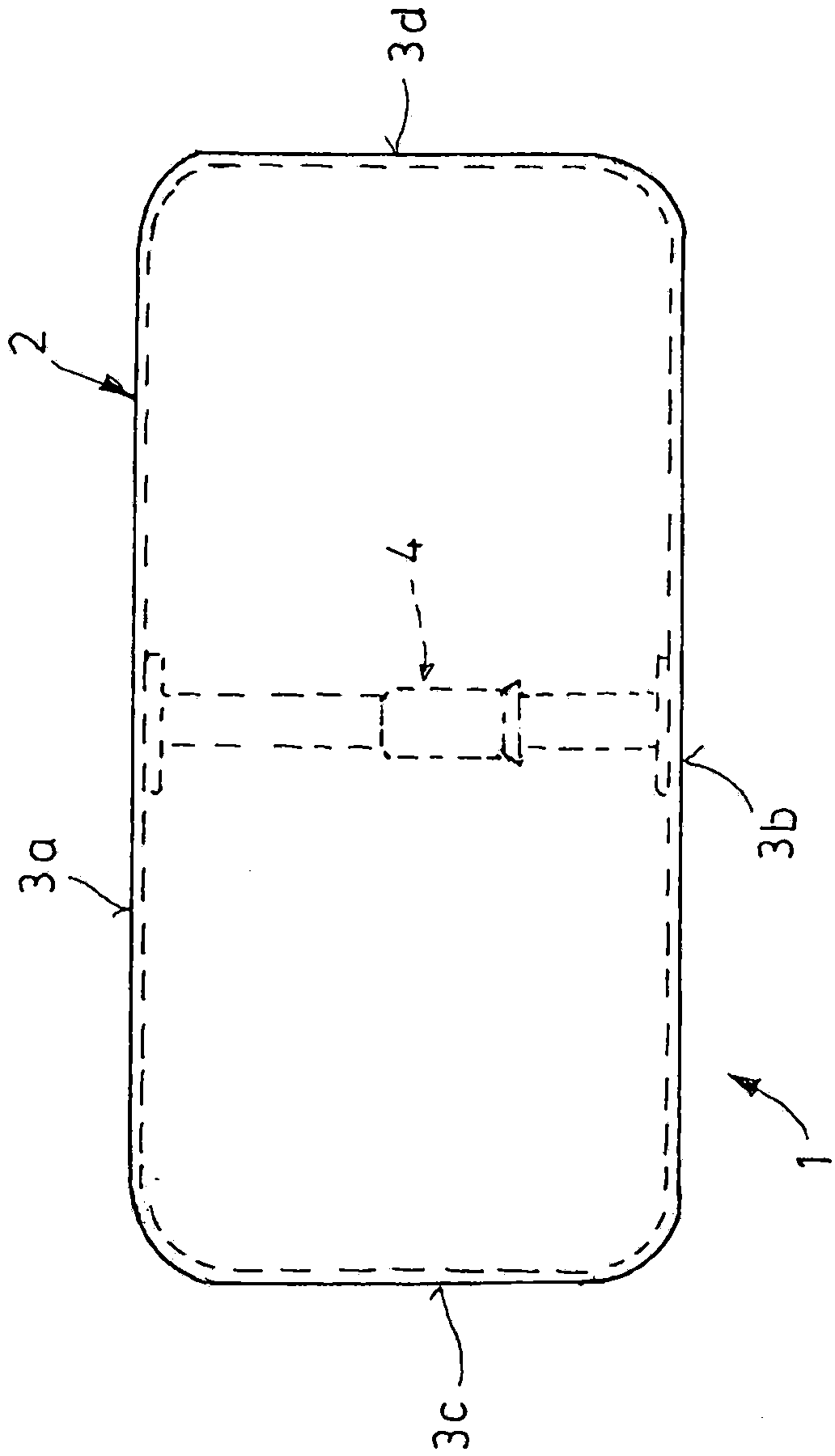

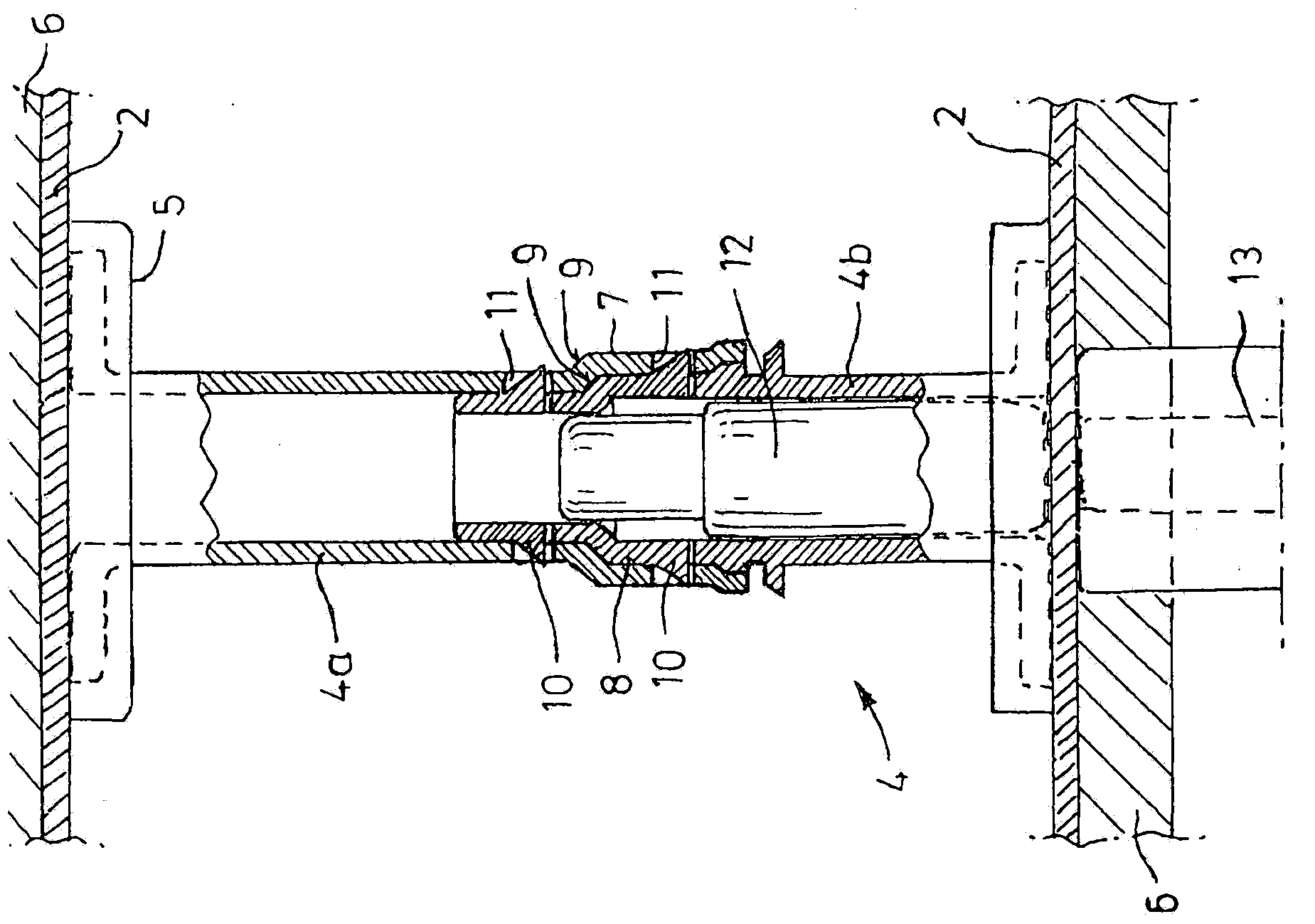

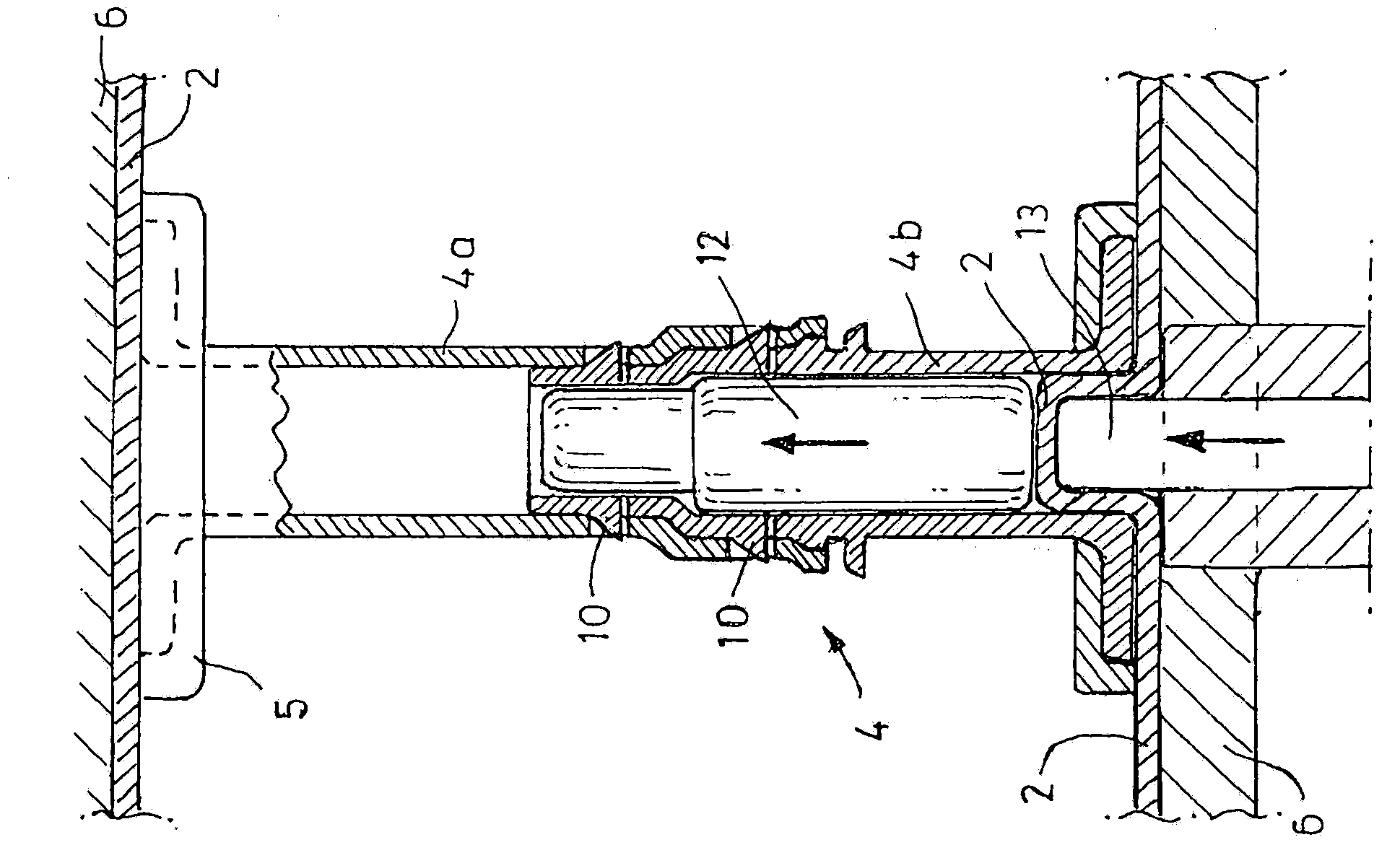

[0038] As already mentioned above, the cabinet 1 according to the invention can be configured, for example, as a fuel tank for a motor vehicle with its usual fittings. figure 1The shown enclosure 1 is shown schematically in a very simplified manner. The cabinet 1 is made in one piece of thermoplastic material and can have any contour, in particular the filler pipe and the drain are not shown for simplicity. The box wall 2 of the cabinet 1 comprises two opposing large-surface wall regions 3a and 3b and two opposing small-surface wall regions 3c and 3d.

[0039] The meaning of the term "monolithic" in the present invention does not exclude the fact that the enclosure consists of two complementary shells. The housings may have been completely welded together at the edges of the peripheral flanges so that the enclosure is substantially closed and integrally formed.

[0040] The cabinet 1 according to the invention is preferably obtained by extrusion blow molding, for example by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com