Welding joint flaw detection device

A flaw detection device and flaw detector technology, applied in transportation and packaging, testing metals, motor vehicles, etc., can solve problems such as the equipment cannot maintain the working posture, the crawler structure is stiff, and the device cannot move normally, so as to achieve high commercial promotion and application value. The technical concept is advanced and practical, avoiding the effect of reducing the adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

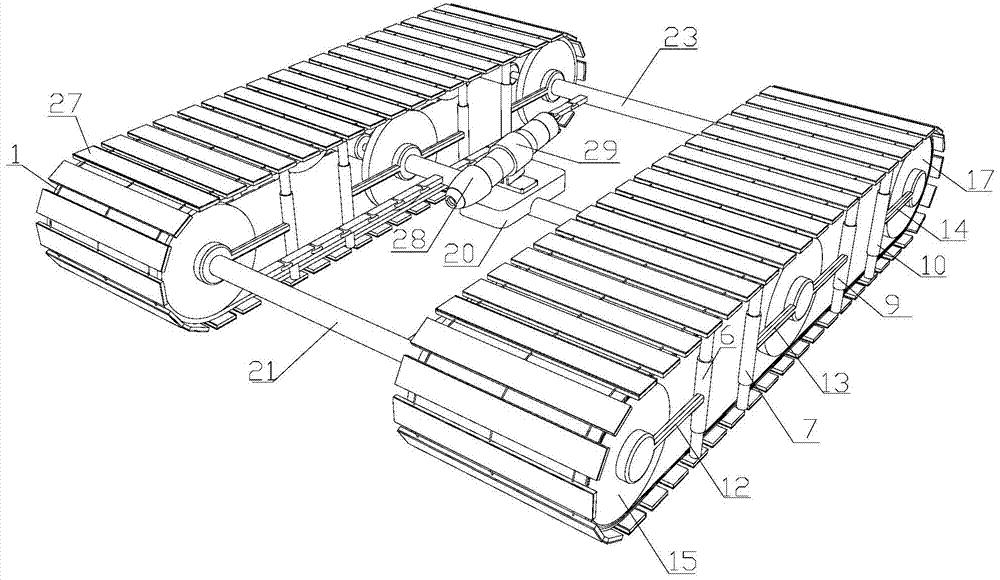

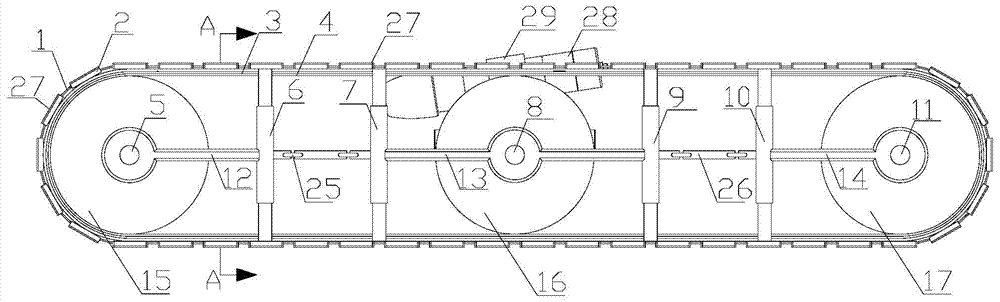

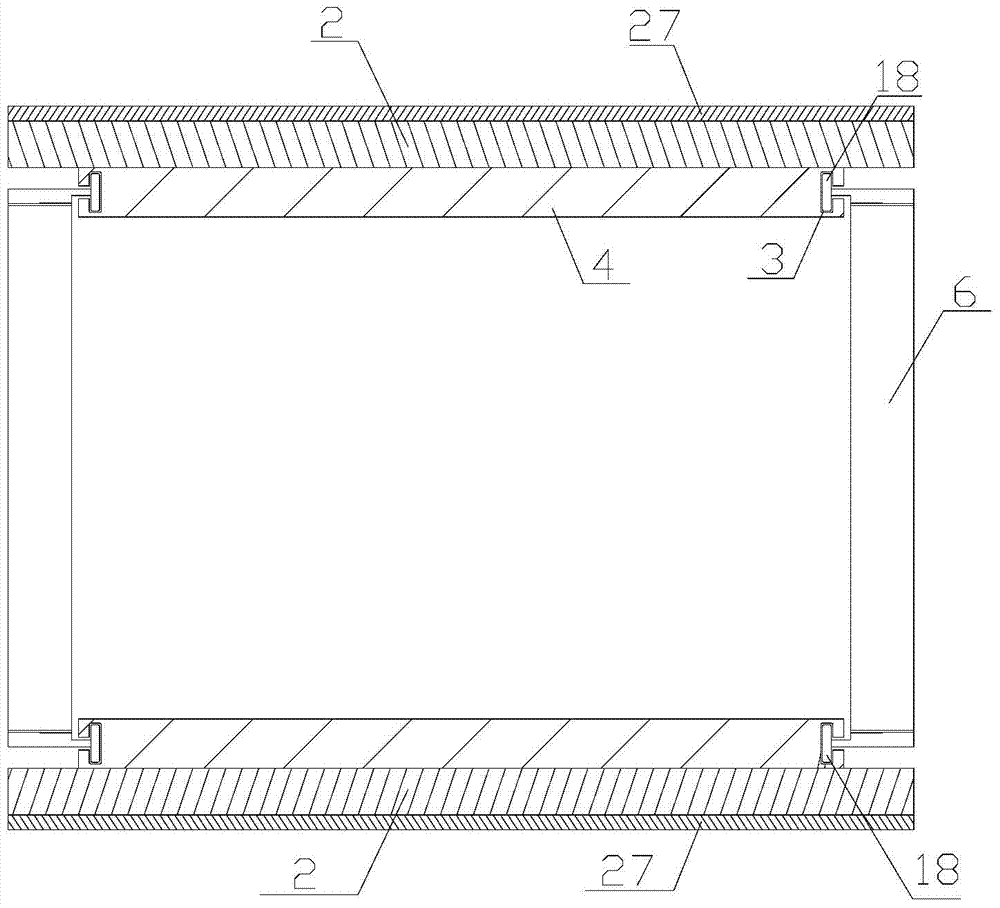

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] As shown in the figure, a weld flaw detection device includes a weld flaw detector 28, and also includes a hull climbing platform on which the weld flaw detector 28 is placed, and the hull climbing platform includes two magnetic drive units, Four sets of belt tension adjustment mechanisms, head beam 21, middle beam 22, tail beam 23, four flexible longitudinals 19 and an equipment mounting base 20, wherein the magnetic drive unit includes a head motor 5, a middle motor 8, a tail motor 11, a Driving wheel 15, secondary driving wheel 16, tail driving wheel 17, track connection hinge 1, permanent magnet 2 and transmission belt 4; the belt tightness adjustment mechanism includes telescopic connecting rod slide rail 3, head hydraulic telescopic connecting rod 6, middle and front hydraulic telescopic connecting rod 7. Middle and rear hydraulic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com