Rack type automatic material transfer device for laminator

A rack-type, laminating machine technology, applied in the direction of conveyors, transportation and packaging, etc., can solve problems such as threats to workers' life safety, and achieve the effects of compact structure, high reliability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

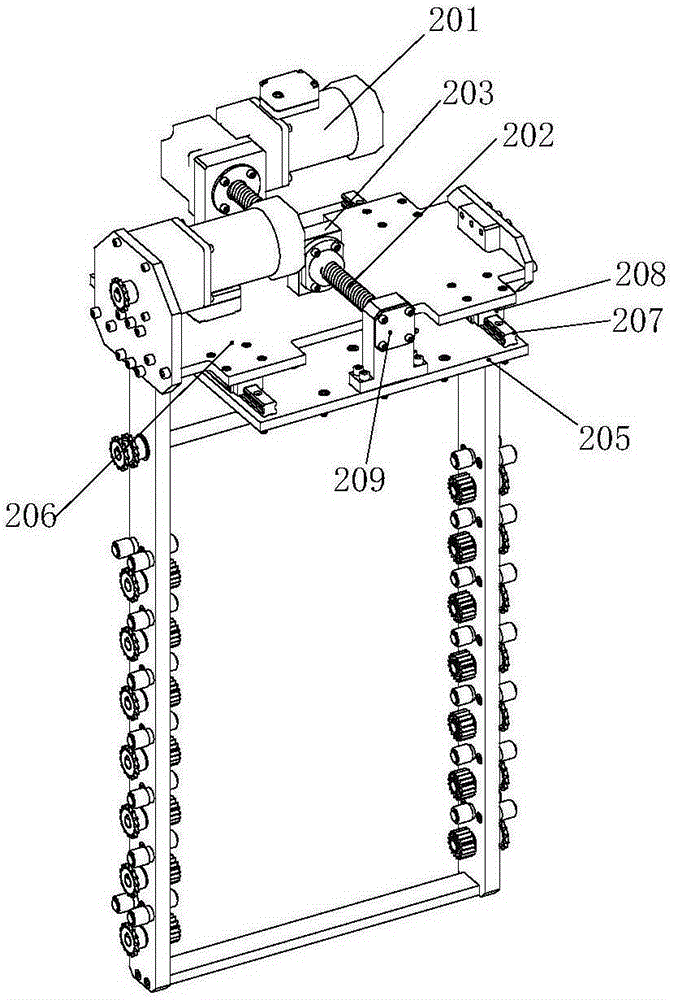

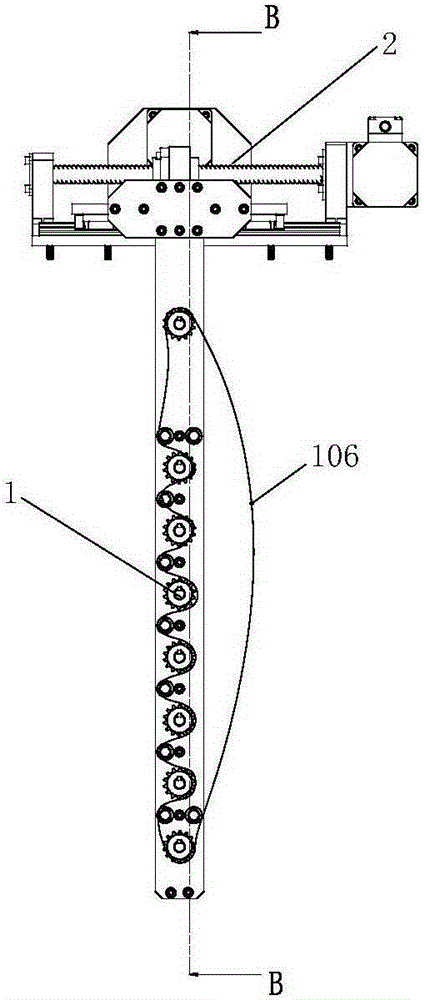

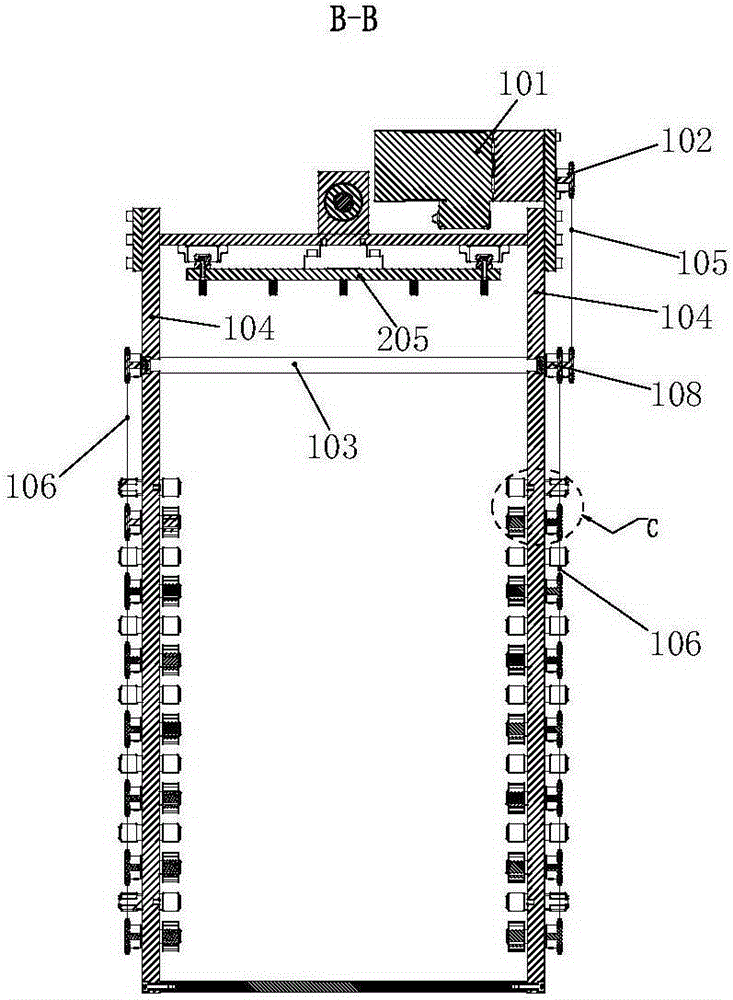

[0021] Such as Figure 1-Figure 5 As shown, the rack-type automatic material transfer device for a laminator of the present invention includes a screw drive device 2 and a gear transfer device 1 .

[0022] The screw drive device 2 includes a first motor 201 , a screw 202 , a screw slider 203 , a movable plate 206 and a bottom plate 205 . The base plate 205 is fixed, the first motor 201 is fixed on the base plate 205 , and the base plate 205 is provided with a bearing seat 209 supporting the screw mandrel 202 . The screw slider 203 is fixed on the movable plate 206 , a guide rail 207 can be arranged on the bottom plate 205 , and a slider 208 which moves along the guide rail 207 is arranged at the bottom of the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com