Automatic stamping device in keyboard glue product production

A stamping device and product technology, which is applied in the direction of flat products, household appliances, and other household appliances, can solve problems such as difficulty in meeting large-scale continuous production, high labor costs, fixed asset investment, and large product quality deviation range, and achieve reduction Human participation, easy quality control, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

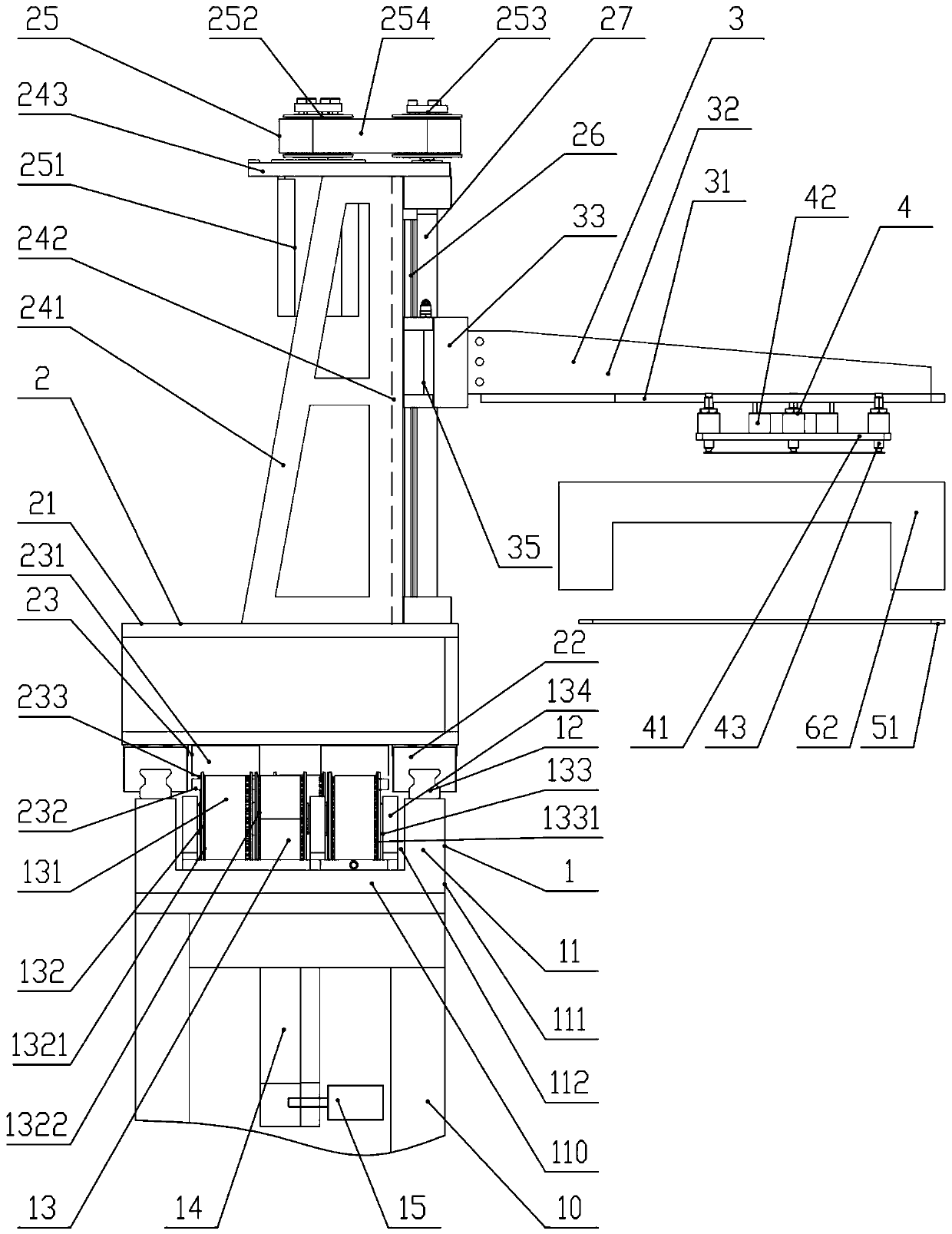

[0049] The present invention will be further described in detail below in conjunction with the drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

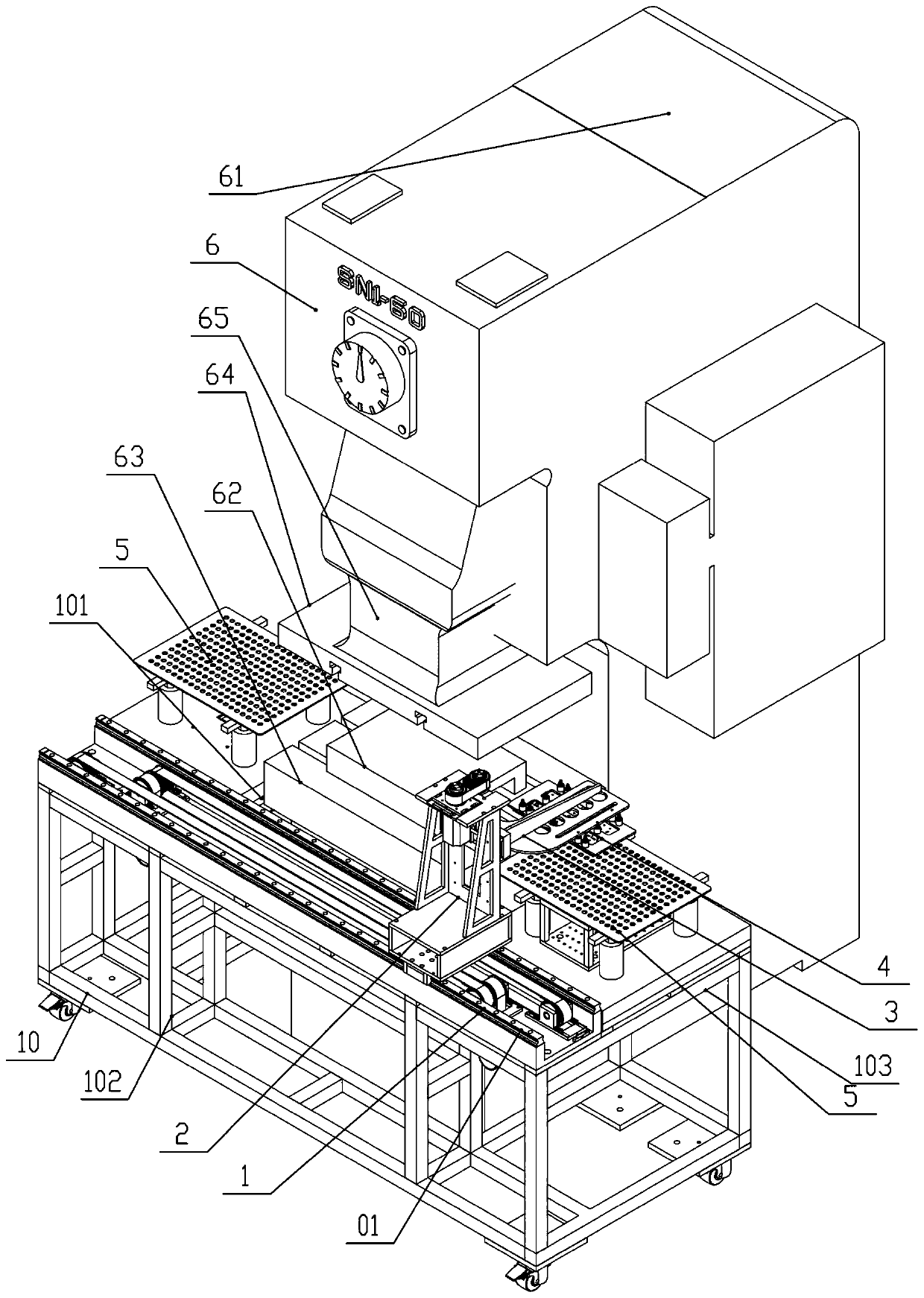

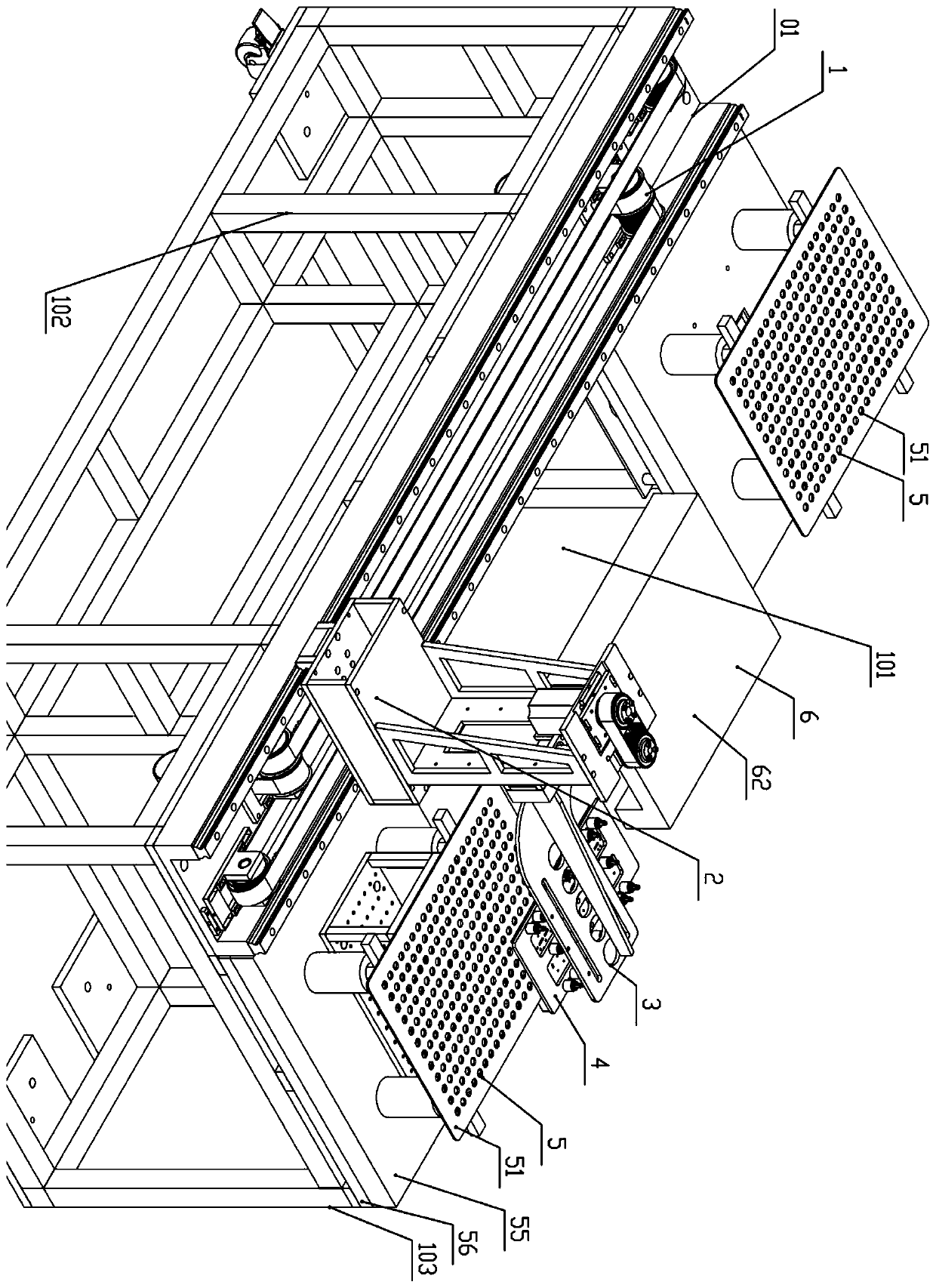

[0050] Figure 1 to Figure 10 It schematically shows an automatic stamping device in the production of a keyboard glue product according to an embodiment of the present invention. As shown in the figure, the device includes an automatic material moving part 01, a punching machine 6 and two lifting tables 5,

[0051] The punching machine 6 includes a machine table 61, a positioning die 62 is fixed on a fixed table surface 63 at the lower end of the machine table 61, and a punching die 64 is fixed on a vertical moving pressure part 65 at the upper end of the machine table 61,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com