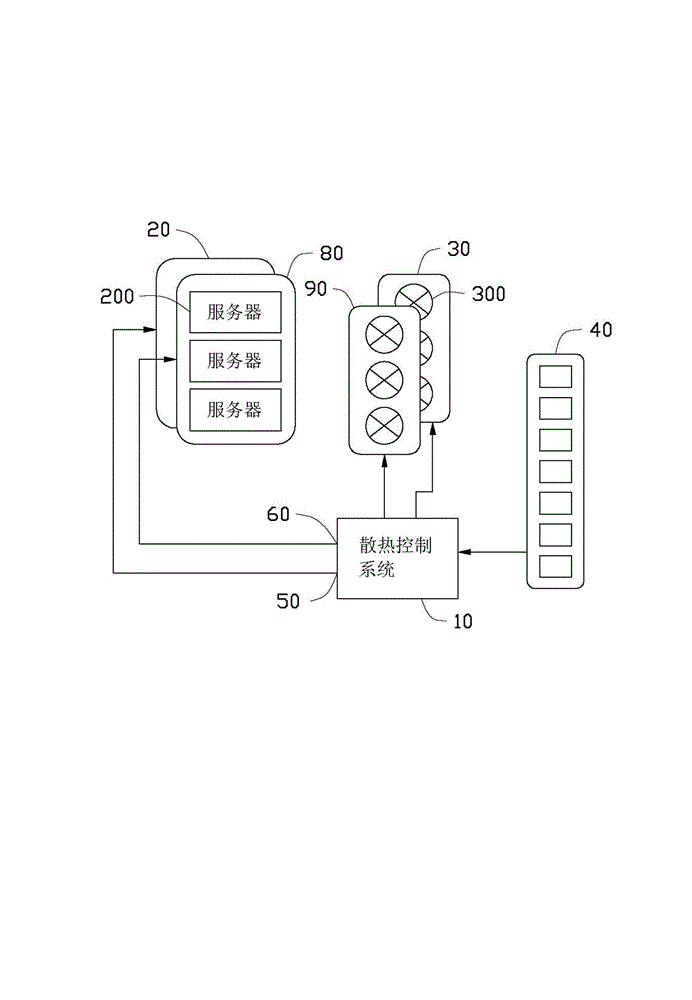

Heat dissipation control system and method

A control system and control method technology, which is applied to pump control, instruments, non-variable pumps, etc., can solve the problems of increased manufacturing costs of servers, and achieve the effect of avoiding manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

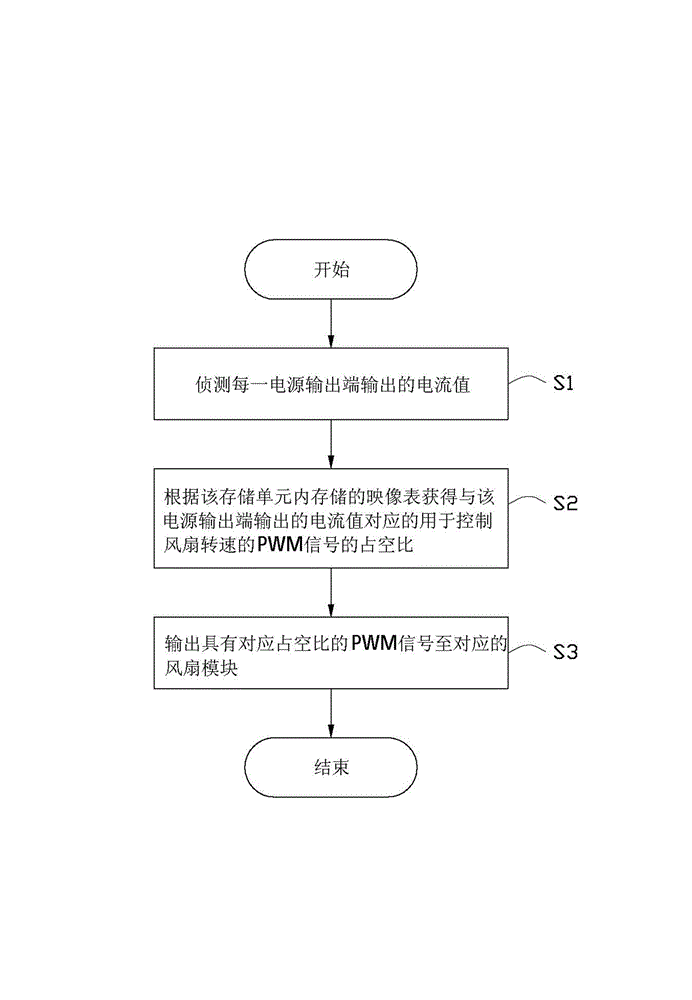

[0026] Please refer to image 3 , The preferred embodiment of the heat dissipation control method of the present invention includes the following steps:

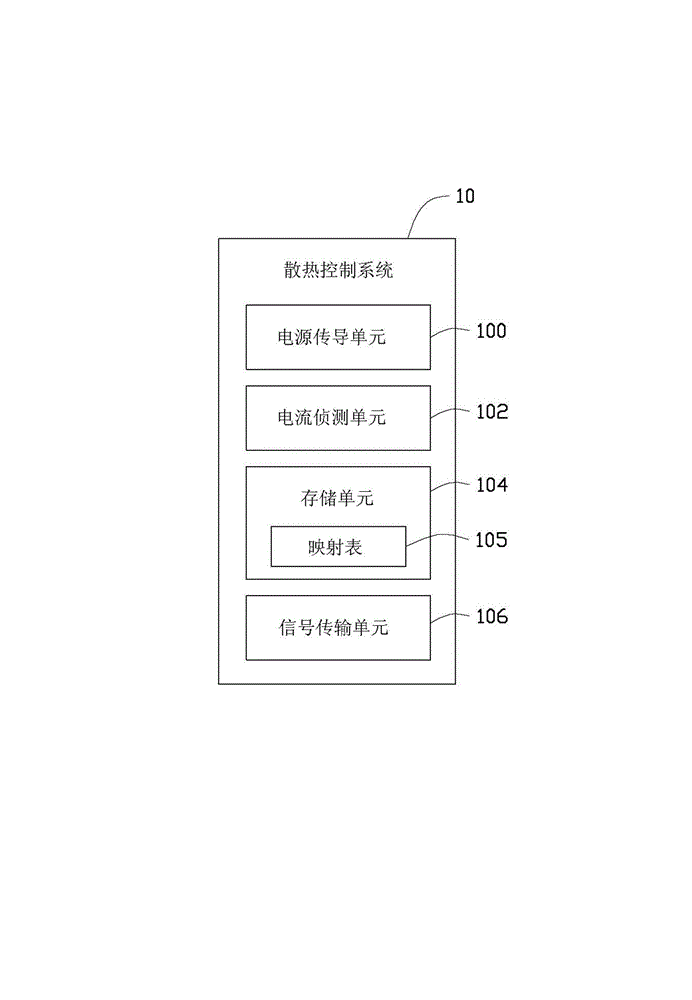

[0027] In step S1, the current detection unit 102 detects the current value output by each power output terminal.

[0028] In step S2, the current detection unit 102 obtains the duty ratio of the PWM signal for controlling the fan speed corresponding to the current value output from the power output terminal according to the mapping table 105 stored in the storage unit 104.

[0029] Step S3, output a PWM signal with a corresponding duty cycle to the corresponding fan module according to the result of the mapping table.

[0030] The heat dissipation control system and method described above control the rotation speed of the corresponding fan by obtaining the current value output by the corresponding power output terminal to achieve the purpose of heat dissipation. This also avoids the disadvantage of increasing the manufacturing cost...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap