Large-scale solid-forging metal framework with lugs and manufacturing method thereof

An integral forging, metal frame technology, applied in the field of material science, can solve problems such as incomparability, and achieve the effects of improving material utilization, shortening processes, and long processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

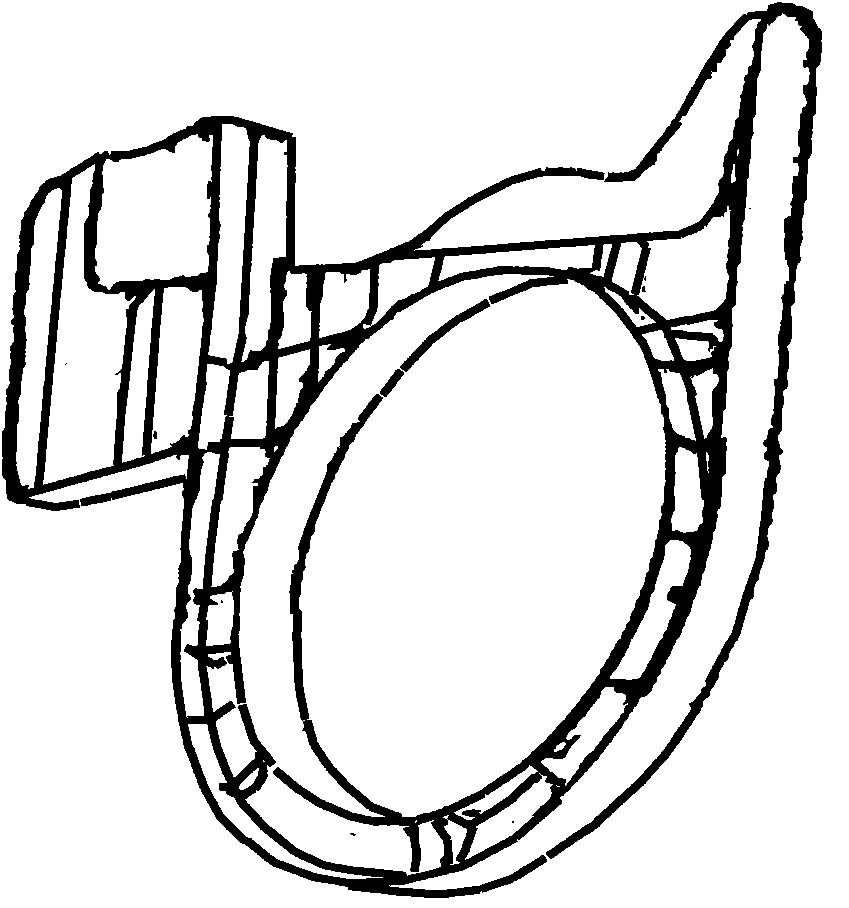

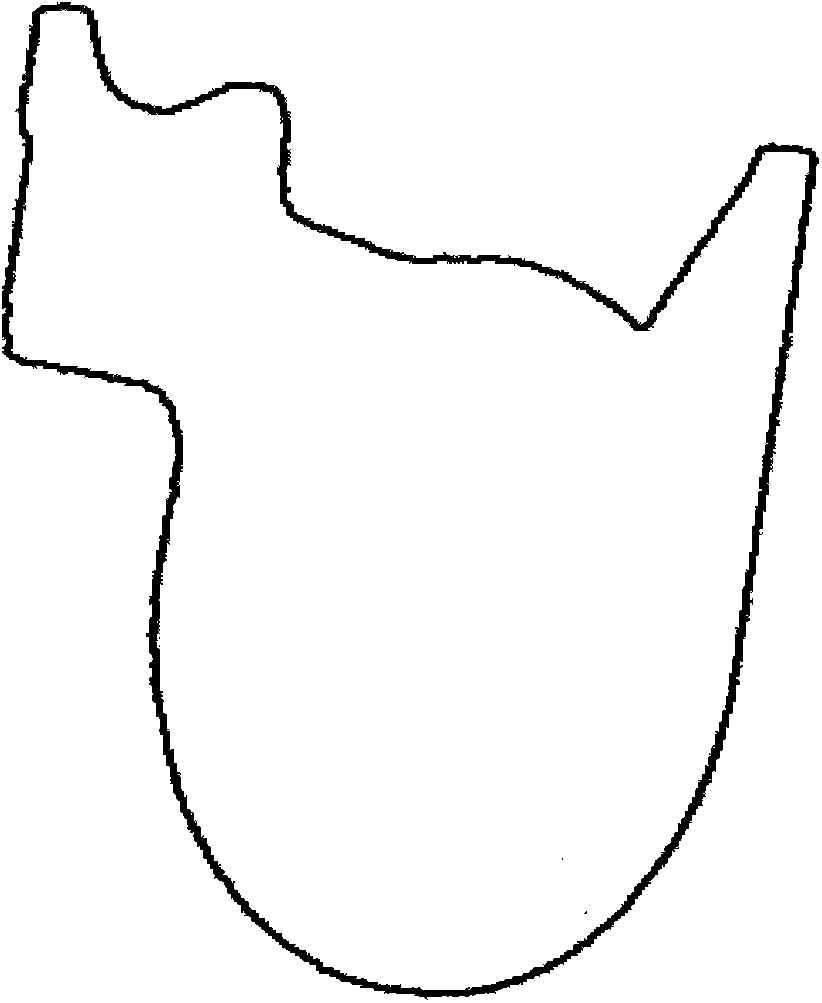

[0033] An embodiment of the present invention will be described below in conjunction with the accompanying drawings. The outline size of the frame is 1528mm×1352mm. The preparation method of the TA15 titanium alloy large frame die forging member with ear pieces at the upper end and the right end is as follows:

[0034] (1) V-shaped blank billet: choose a bar with a diameter of Φ400mm, and blank it after upsetting and drawing to obtain a slab with uniform thickness. By applying pressure on the slab, a V-shaped blank is prepared. The pressure acts on the corresponding V-shaped blank. The bottom of the bottom, wherein, the included angle and extension length of the V-shaped blank are corresponding to the included ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com