Turning device for large vertical containers

The technology of a vertical container and a turning device is applied in the direction of a lifting device, a hoisting device, etc., which can solve the problems of inconvenient operation, hidden safety hazards, etc., and achieve the effect of a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

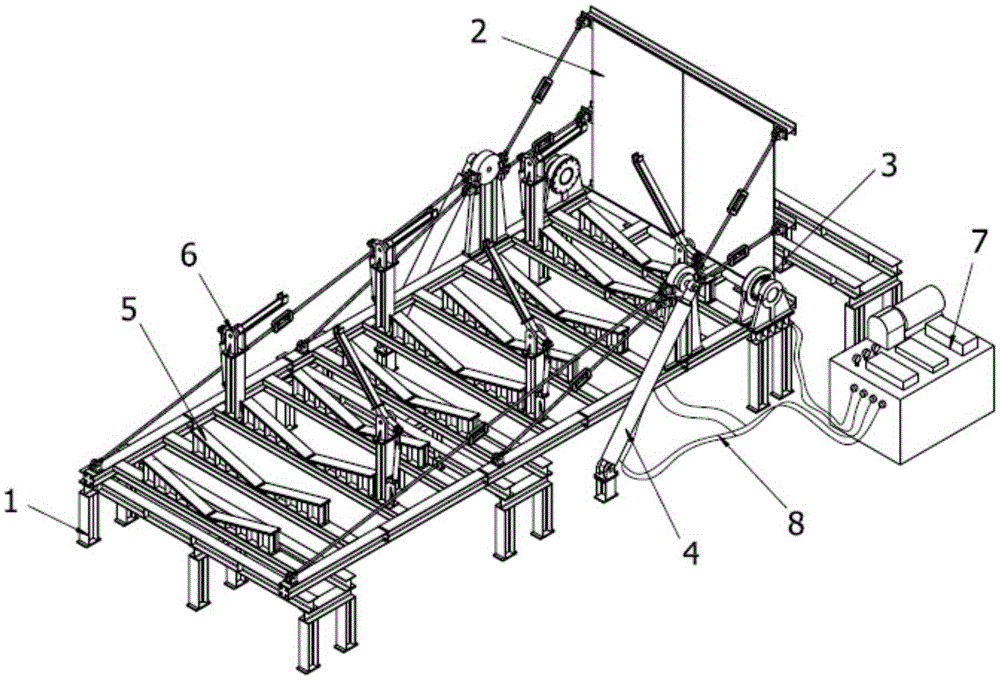

[0020] like figure 1 As shown, the present invention comprises: several fixed brackets 1, the overturn bracket 2 that is relatively pivotally connected on several fixed brackets 1 through the support shaft 3, the main hydraulic cylinder 4 that is arranged between the fixed bracket 1 and the overturn bracket 2, relatively Several container support frames 5 and container fixing devices 6 installed on the flip support 2 , wherein the main hydraulic cylinder 4 and the container fixing device 6 are connected to the hydraulic station 7 through a hydraulic pipeline 8 .

[0021] The container supporting frame 5 is a V-shaped structure.

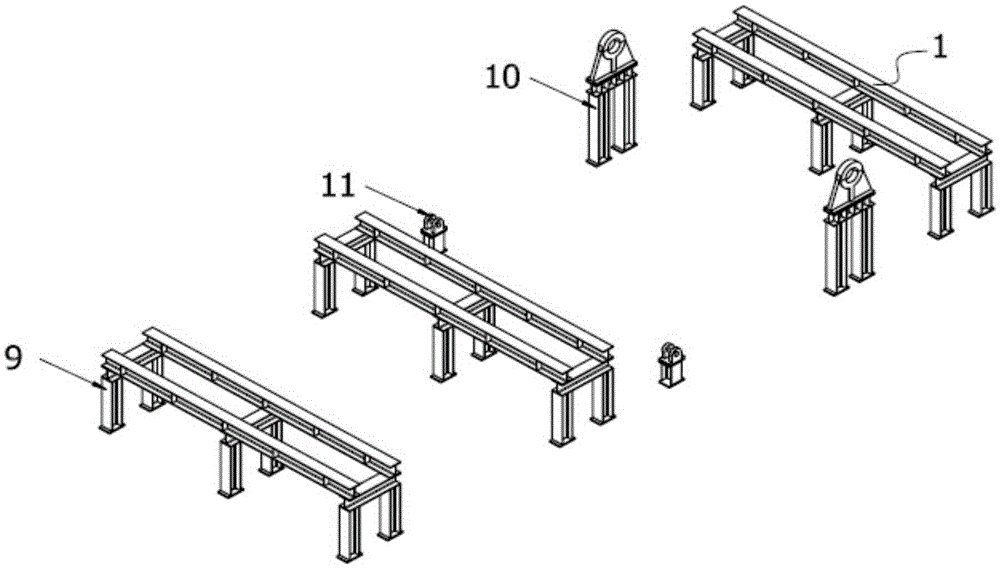

[0022] like figure 2 As shown, several fixed brackets 1 are frame-type structures, which are respectively used as: the flip bracket support frame 9, the support shaft lower support frame 10, and the main hydraulic cylinder lower support frame 10.

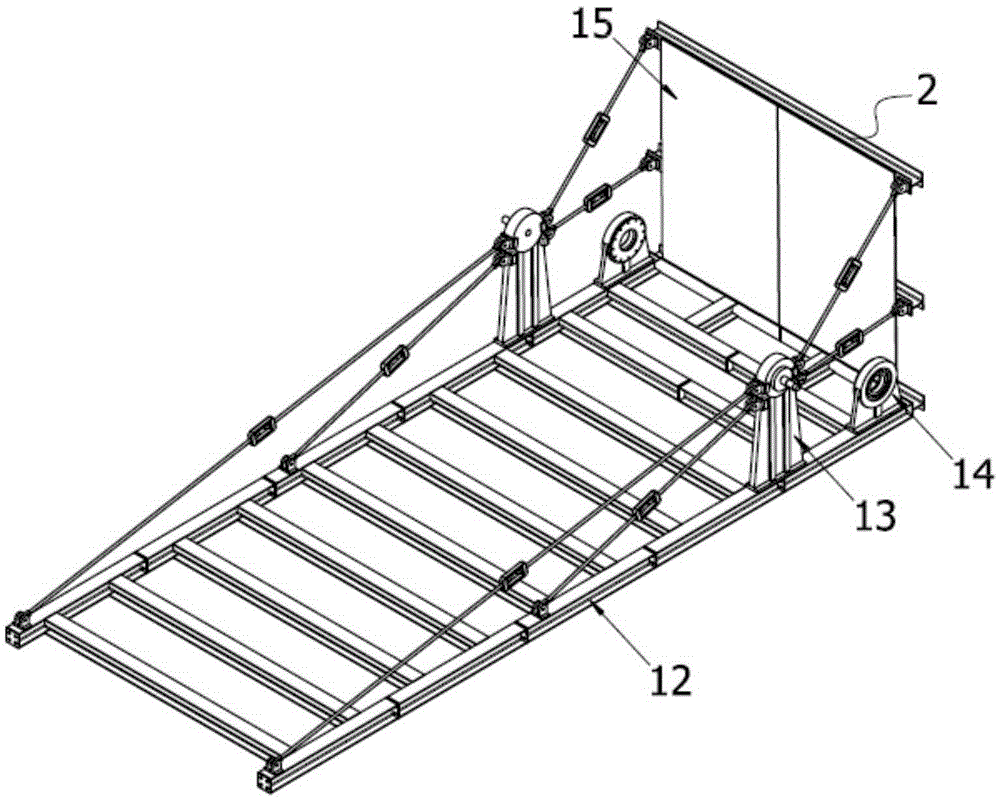

[0023] like image 3 , Figure 4 As shown, the overturn support 2 includes: an L-shaped frame 12, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com