Blast Furnace Shaft and Bosh Temperature On-Line Detection Sensing System

A sensing system and blast furnace technology, which is applied in the field of blast furnace temperature detection, can solve the problems such as the absence of research literature, and achieve the effect of ensuring furnace conditions and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

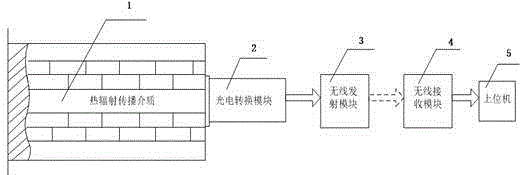

[0019] Such as figure 1 As shown, the present invention provides an on-line detection and sensing system for the temperature of a blast furnace body and bosh. The on-line detection and sensing system includes a heat radiation propagation medium 1 installed in a blast furnace wall, and a photoelectric conversion module 2, The wireless transmitting module 3, the wireless receiving module 4 and the upper computer 5, the heat radiation propagation medium in the furnace wall is connected with the photoelectric conversion module, the photoelectric conversion module is connected with the wireless transmitting module, the wireless transmitting module is connected with the wireless receiving module, and the wireless receiving module is connected with the upper computer connect.

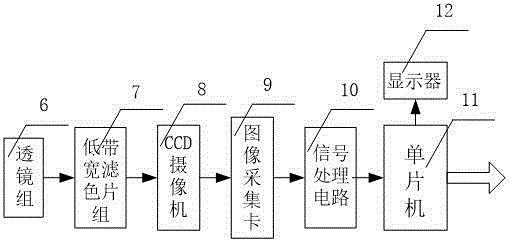

[0020] Such as figure 2 As shown, the photoelectric conversion module includes: lens group 6, low-bandwidth color filter group 7, CCD camera 8, image acquisition card 9, signal processing circuit 10, single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com