Coal-bed gas well bottom sand removing device

A coalbed methane well and sand cleaning technology, which is applied in the direction of wellbore/well components, flushing wellbore, earthwork drilling and production, etc. It can solve the problems of production layer influence, high equipment pressure, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

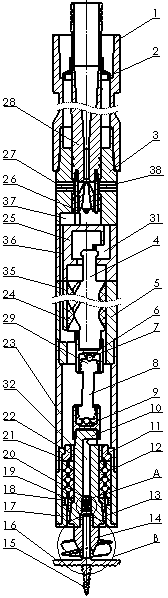

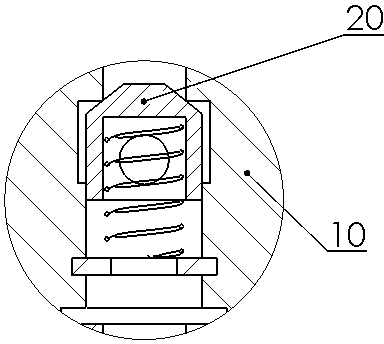

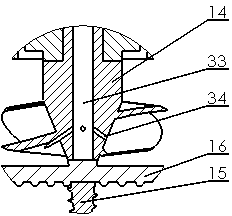

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 As shown, a coalbed gas well bottom sand removal device of the present invention mainly consists of an outer cylinder 1, a support frame 2, a connecting pipe 3, a screw rotor 4, a stator 5, a transmission shaft 10, a string bearing 12, an impeller 14, and a traction head 15 , Crushing knife 16, cone valve 20, rubber bushing 24, flow channel connecting pipe 25, nozzle 27, diffuser pipe 28, cardan shaft 29. The support frame 2 is installed between the outer cylinder 1 and the diffuser pipe 28, and is used for the radial positioning of the diffuser pipe 28; 28. The connecting pipes 3 are connected by bolts 26; the rubber bushing 24 is pressure-injected on the inner wall of the stator 5; The two ends of the screw rotor 4 and the transmission shaft 10 are respectively connected. The cone valve 20 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap