Bearing acoustic diagnosis system and method used in combination with wheel set bearing running-in machine

A bearing and acoustic technology, applied in the field of acoustic diagnosis system of railway vehicle bearings, to achieve the effect of increasing working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

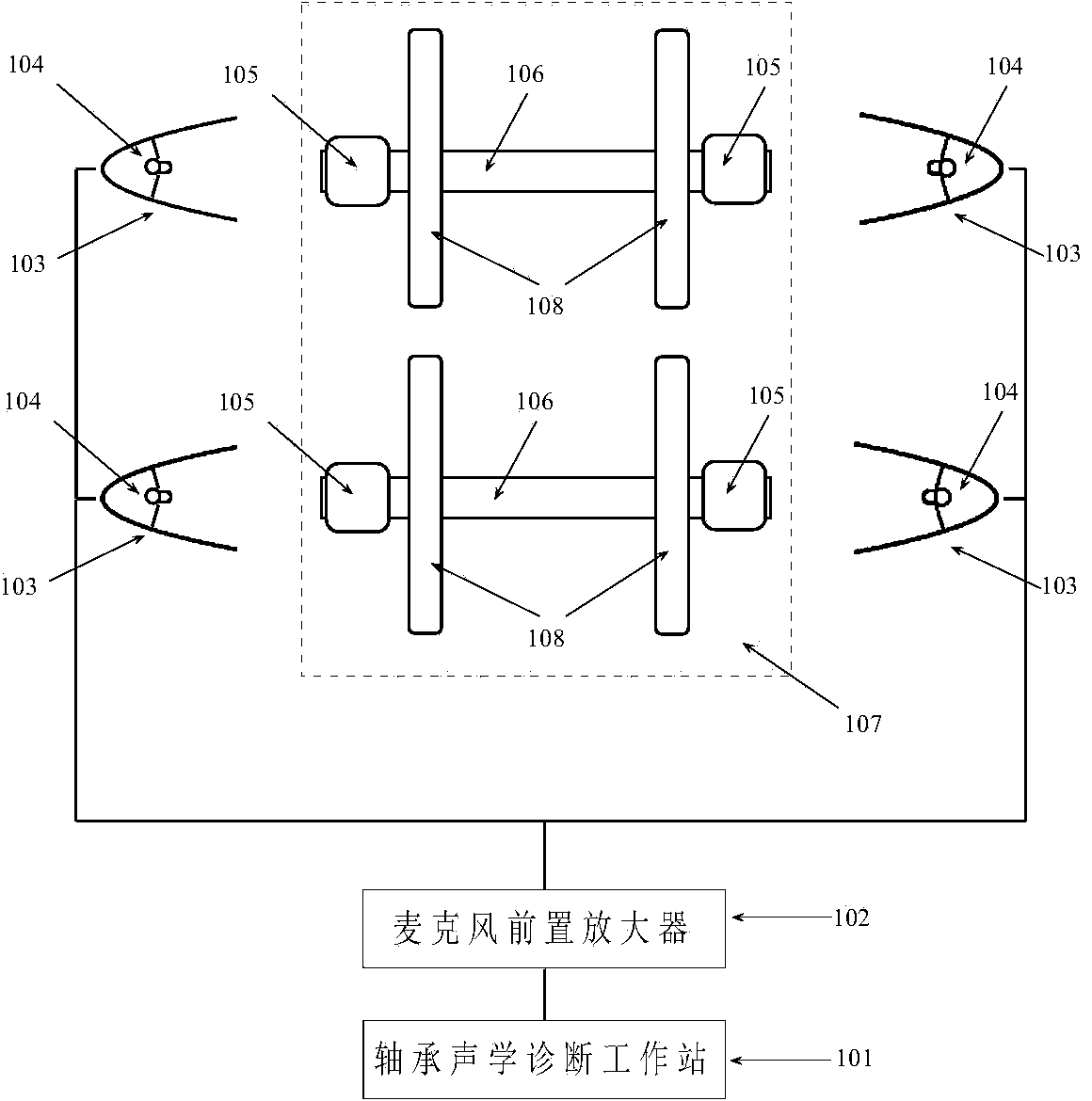

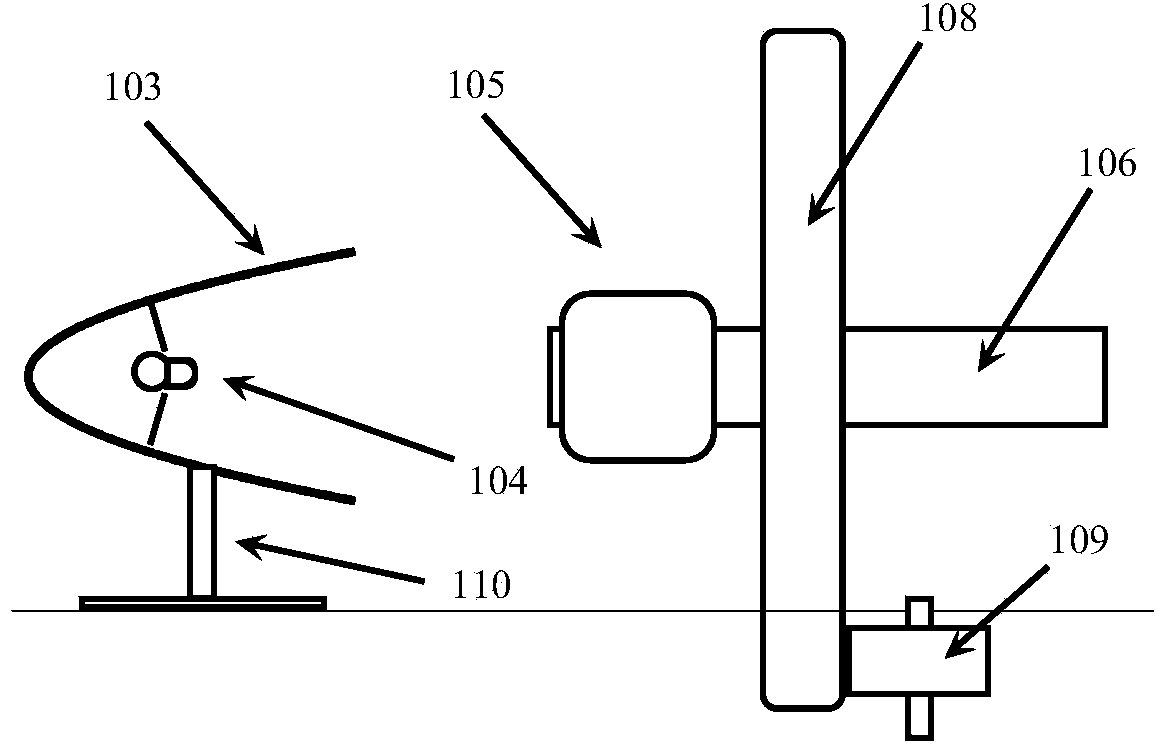

[0029] A bearing acoustic diagnosis system combined with a wheel set bearing running-in machine, such as figure 1 , figure 2 As shown, it includes a bearing acoustic diagnosis workstation 101, a microphone 104, a microphone sound cover 103, and a microphone preamplifier 102;

[0030] The microphone 104 is located in the microphone cover 103, the microphone cover 103 is fixed on the outside of the bearing 105 within the range of 100mm to 1m through the support frame 110, the central axis of the microphone cover 103 is at the same height as the central axis of the bearing 105, and the microphone The opening direction of the sound cover 103 is facing the outer end cover of the bearing 105 .

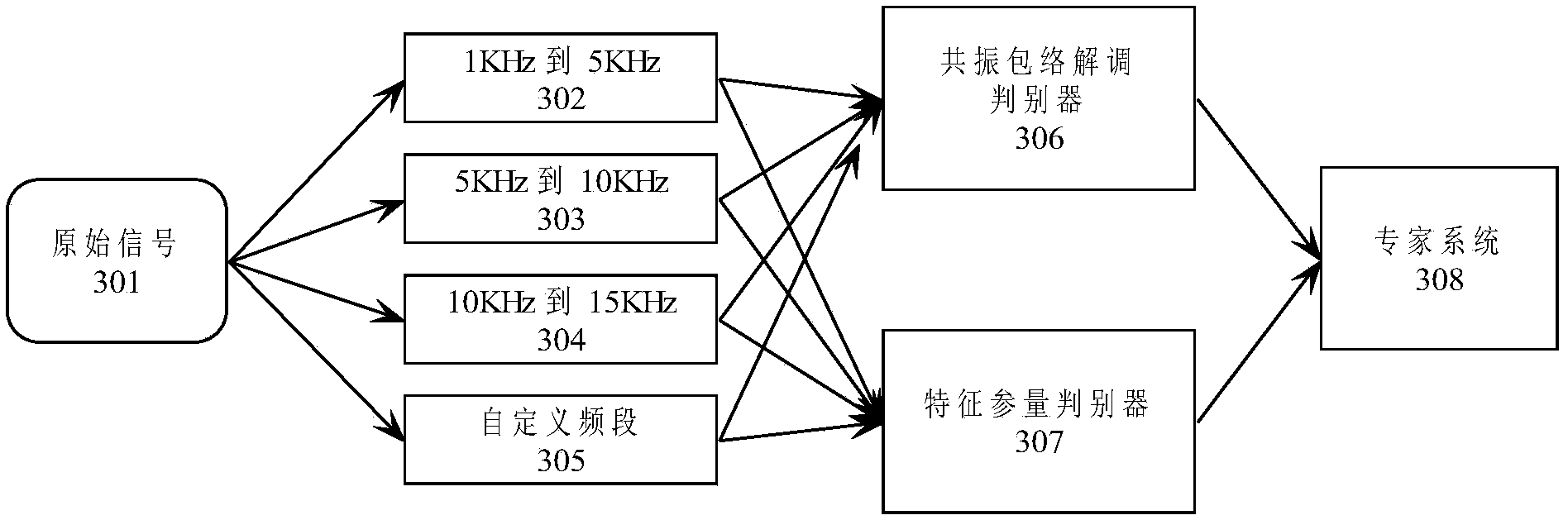

[0031] The microphone 104 collects the sound signal of the bearing to form a microphone signal, which is input to the bearing acoustic diagnosis workstation 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com