Nodal Stiffness Prediction Method Based on Vibration Test

A prediction method, vibration testing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unreliable indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

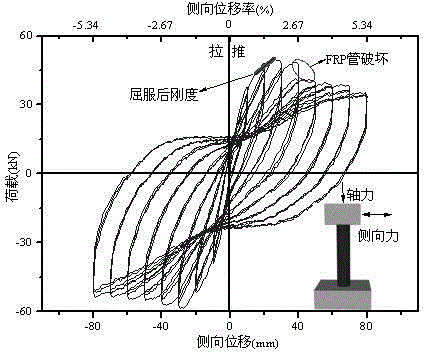

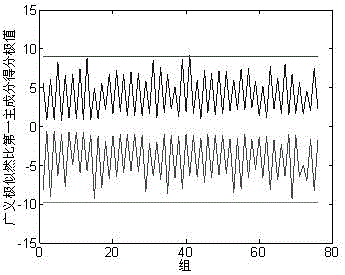

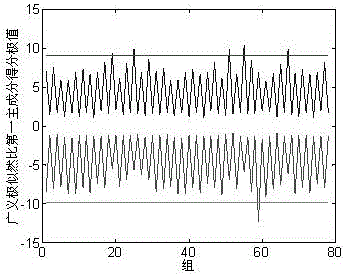

[0085] The present invention is a method for predicting node stiffness based on vibration testing. First, a model (finite element model or test model) of nodes (beam-column nodes, pier-column plastic hinges, etc.) The extreme value of the first principal component score of the analysis is used as the control index, and the relationship curve between the ratio of the control index exceeding the upper and lower limits and the node stiffness under different damage conditions (different node stiffness) is established in the statistical quality control chart; secondly, in In actual engineering, measure the vibration response of the node, and calculate the proportion of the control index exceeding the upper and lower limits in the statistical quality control chart based on the response; finally, substitute the proportion of the control index exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com