Cross special-shaped spinneret plate

A cross-shaped, spinneret technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve problems such as less than ideal, achieve uniform cooling, good spinning effect, and avoid mutual adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

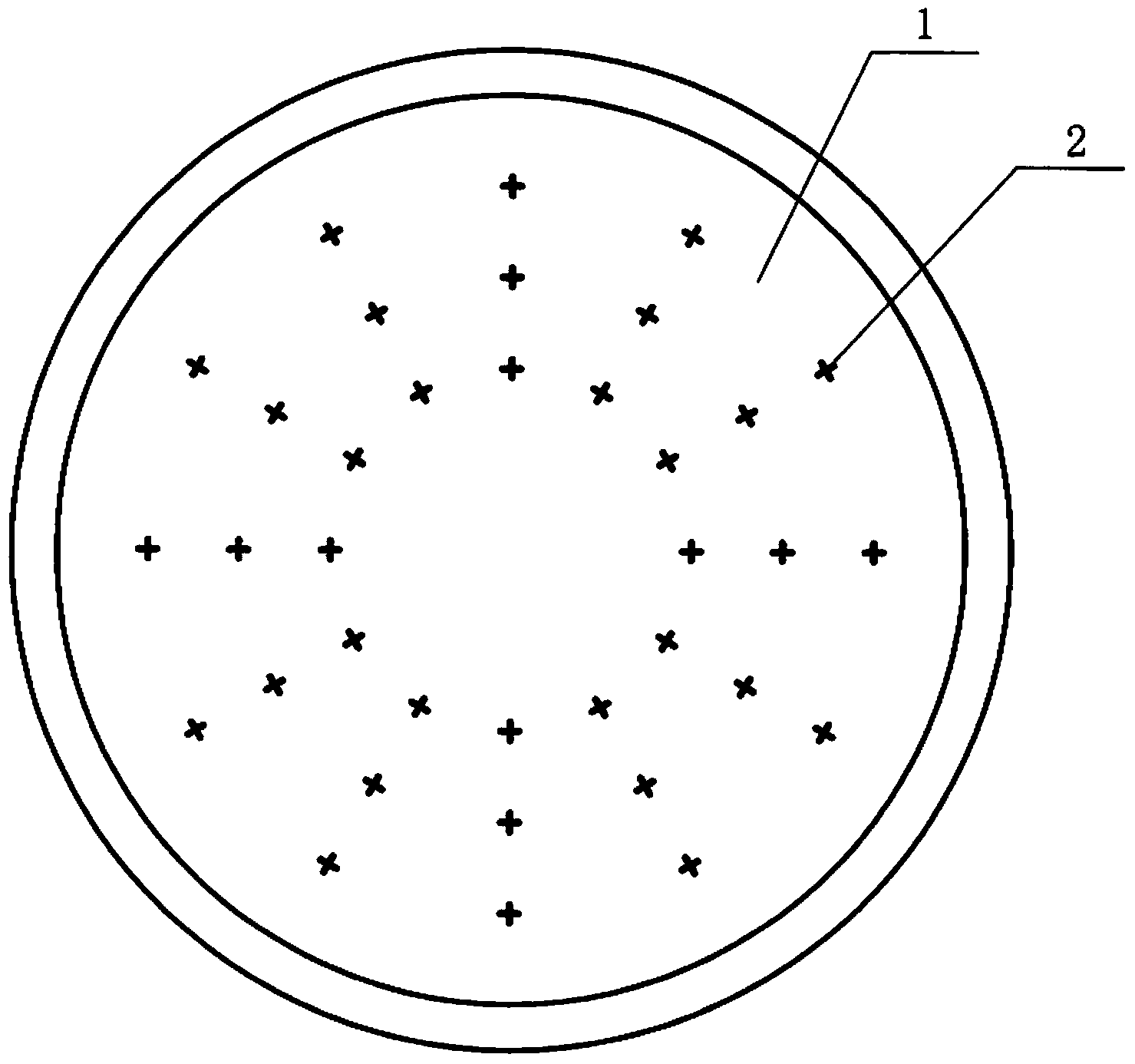

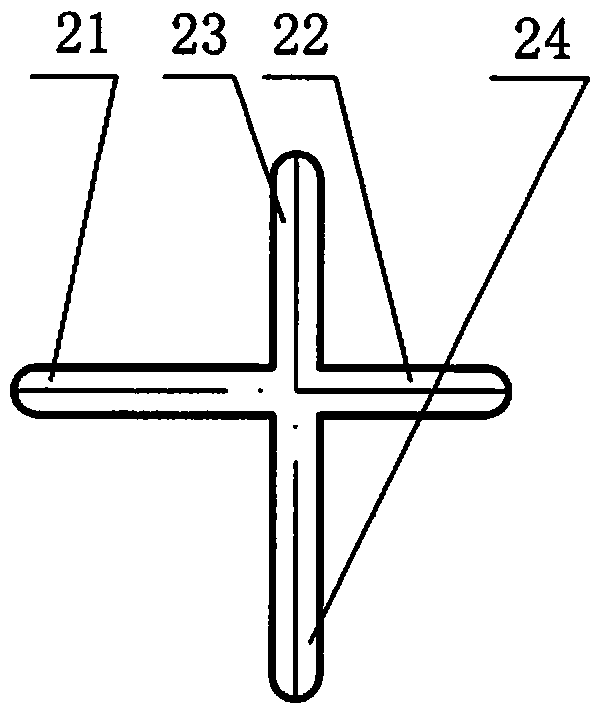

[0015] like figure 1 , figure 2 Shown: the present invention comprises body 1, a plurality of spinneret microholes 2 that are arranged on the lower end surface of body 1, the cross-sectional shape of spinneret microhole 2 is cross-shaped, and the lengths of each side of cross-shaped 21, 22, 23, 24 are different Similarly, the intersection points of the spinneret microholes 2 are radially arranged with the body 1 as the center, and the intersection point of the adjacent spinneret microholes is 30 degrees from the center of the body; the cross-shaped transverse microholes 21, 22 and the longitudinal microholes 23 and 24 have a width of 100 microns to 200 microns, and the ratio of the length dimension to the width dimension of the spinneret microholes cross-shaped transverse microholes 21 and 22 is 6 to 12, and the spinneret microholes cross-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com