T-shaped polyester fiber spinneret plate

A polyester fiber and spinneret technology, applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problem that the pressure consistency in the spinneret microholes cannot be guaranteed, the spinning stability is affected, and the effect is not ideal and other problems to achieve the effect of avoiding mutual adhesion, good spinning effect and high rate of abnormal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

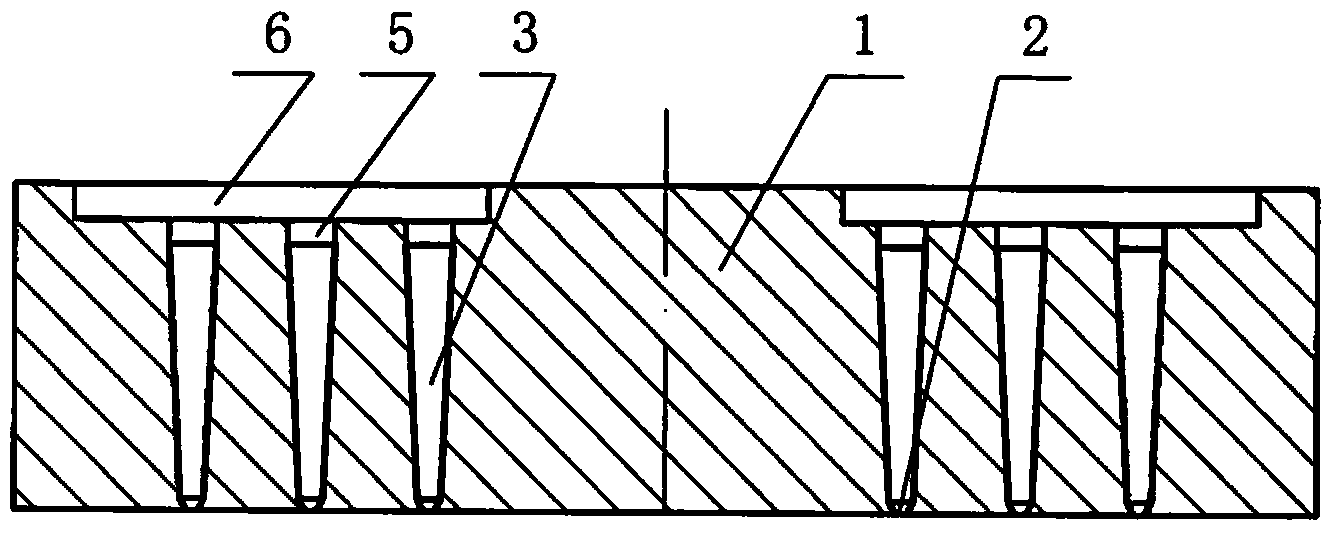

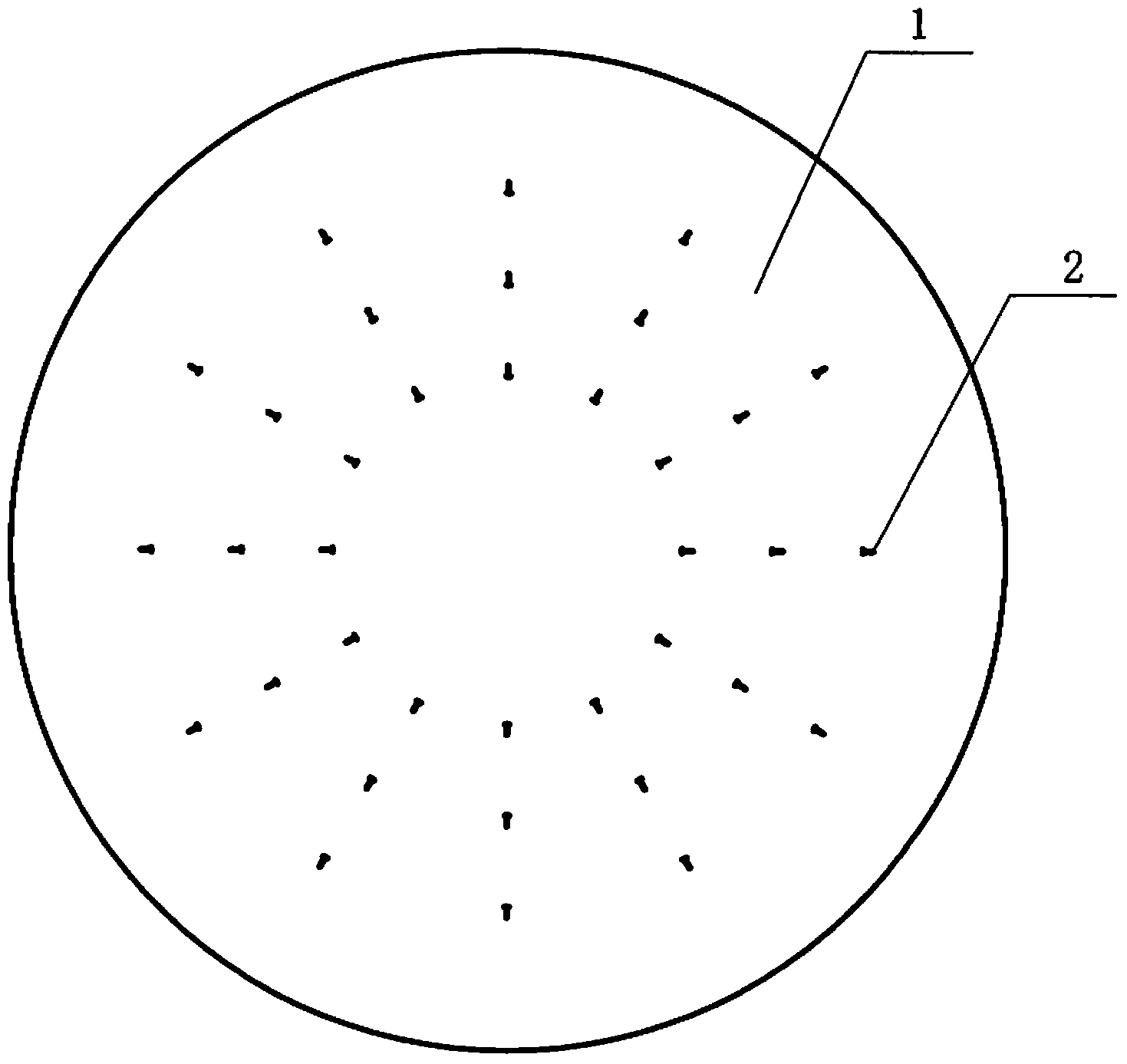

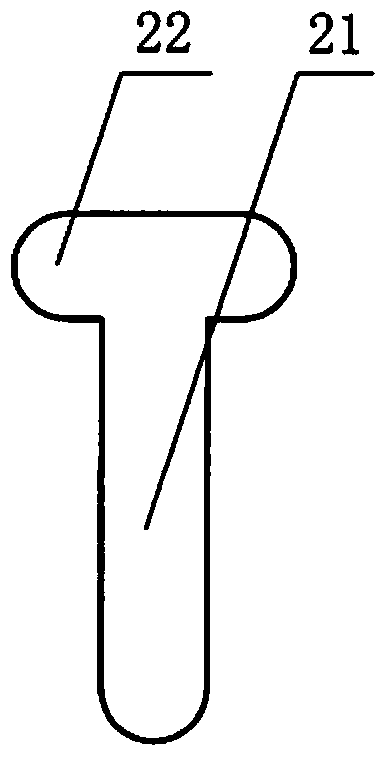

[0016] Such as Figure 1 to Figure 4 As shown: the present invention includes a body 1, a number of spinneret microholes 2 arranged on the lower end surface of the body 1, the cross-sectional shape of the spinneret microholes 2 is T-shaped, and the spinneret microholes 2 are arranged radially, T-shaped The center line of the longitudinal microhole passes through the center of the body, the length ratio of the T-shaped longitudinal microhole 21 to the transverse microhole 22 is 1.2 to 1.5, and the melt guide hole 3 is arranged above the spinneret microhole 2, and the melt guide hole 3 is in the shape of an inverted cone In a table shape, the upper end of the melt guide hole 3 is connected to the melt guide groove 5 , and a melt distribution groove 6 is arranged above the melt guide groove 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com