Turbine driving rotary spraying device used for assisting in lifting marine drilling platform pile shoe

An offshore drilling platform and turbine technology, which is applied to spray devices, jet devices, valve devices and other directions with movable outlets, can solve the problem that the adsorption of seabed sediment cannot be quickly relieved, the jet flushing area is small, and the rapid jet flushing effect cannot be achieved. and other problems to achieve the effect of shortening the transfer period of the work area, improving the spraying effect, and accelerating the lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

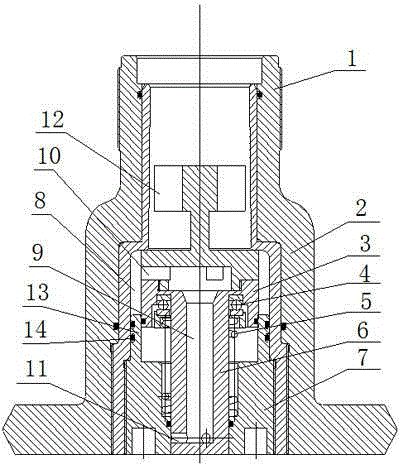

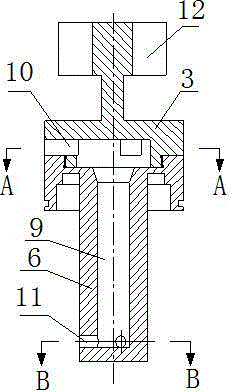

[0017] The working process of the rotary spray flushing device of the present invention is as follows:

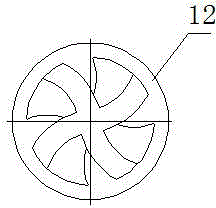

[0018] High-pressure water enters from the interface pipe, pushes the valve core to move down, the valve core moves down in conjunction with the valve stem, the lower end of the valve stem protrudes from the end cap, high-pressure water enters the interface pipe, the impingement turbine drives the valve core to rotate, and then enters the valve cavity through the water inlet hole Enter the blind hole in the center of the valve stem, and then spray out from the spray hole at the lower end of the valve stem along the blind hole. Since the valve core drives the valve stem to rotate, the spray hole rotates to spray water. When the high-pressure water in the mouthpiece is closed, the valve stem As the spool moves up, the injection hole at the lower end of the valve stem retracts upwards into the middle hole of the end cap, the injection hole is closed, and the cleaning operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com