A mobile maintenance platform for high-voltage circuit breaker mechanism box

A high-voltage circuit breaker and maintenance platform technology, which is applied to switchgear, electrical components, etc., can solve the problems that the personal safety of maintenance personnel cannot be effectively guaranteed, the disassembly and assembly cannot be kept stable, and maintenance work is time-consuming and labor-intensive. It is easy to disassemble and installation work, convenient for safe operation, and convenient for maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

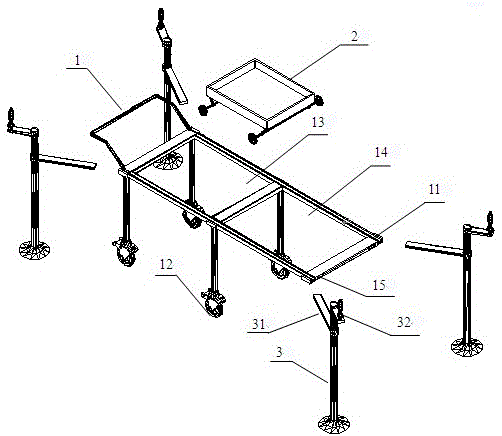

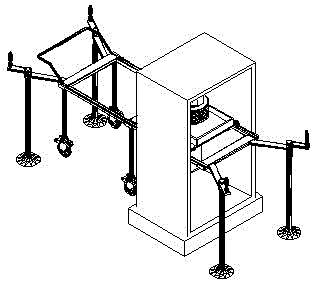

[0022] Such as figure 1 Shown is a specific embodiment of the present invention, the high-voltage circuit breaker mechanism box mobile inspection platform includes a mobile device 1, an inspection platform 2 and an adjustment support device 3, and the inspection platform 2 is movably arranged on the mobile device 1. The adjustment support device 3 is detachably connected with the mobile device 1 to realize the adjustment and fixed support of the vertical height of the mobile device 1 .

[0023] As a preferred mode, the mobile device 1 is configured as a mobile rail car, and the bottoms of the four legs of the mobile rail car are respectively provided with universal wheels 12, which is the simplest and most convenient structure. Of course, the mobile device 1 can adopt other A device capable of movement.

[0024] As a preferred mode, the top of the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com