Phase change heat storage type intelligent high-temperature rapid fermentation apparatus for kitchen garbage

A kitchen waste and fermentation device technology, which is applied in the field of phase-change thermal storage type kitchen waste intelligent high-temperature rapid fermentation device, can solve the problems of difficult temperature control, low energy density, large volume, etc., and achieve flexible distribution and heat storage energy The effect of high density and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiments.

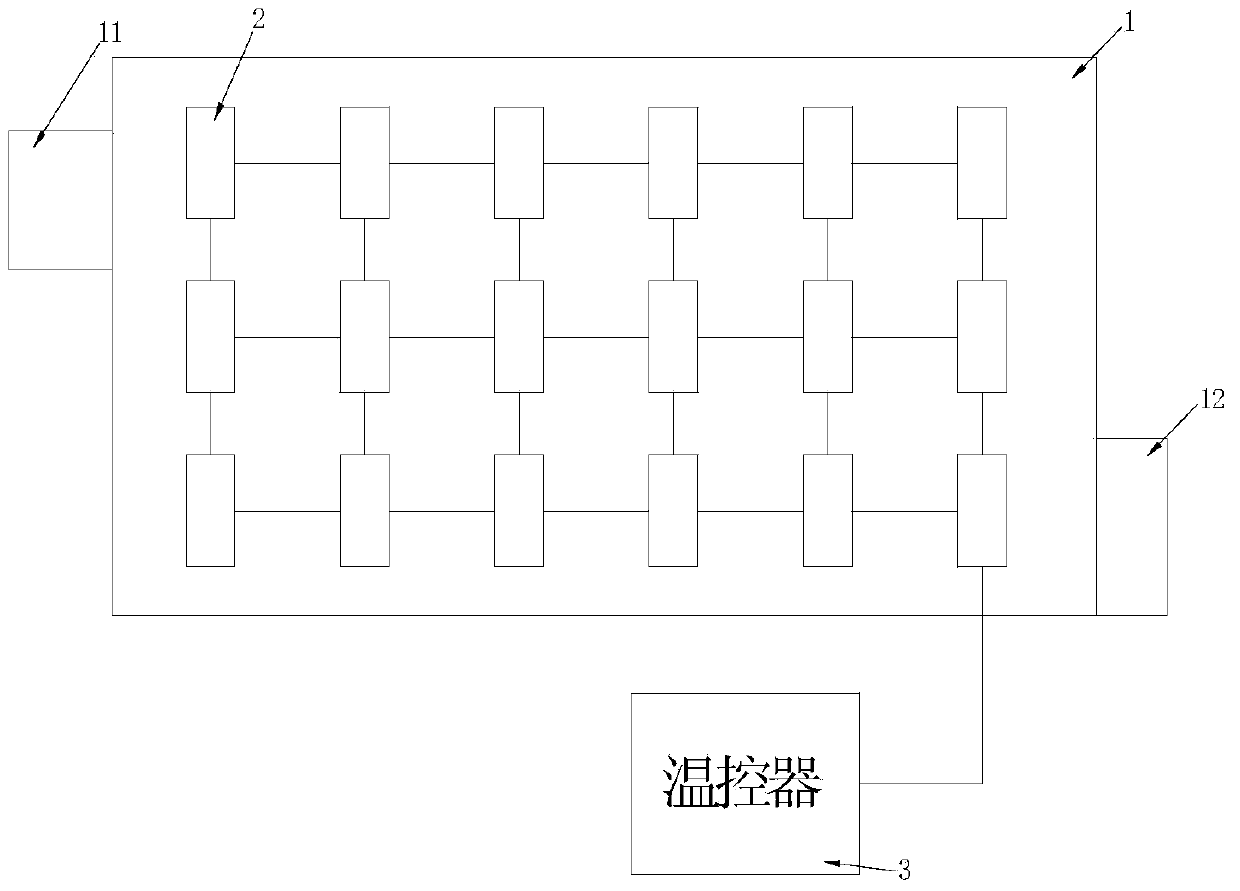

[0019] Such as figure 1 As shown, a feed port 11 and a feed port 12 are preset on the fermentation cabin 1 for putting in and taking out kitchen waste.

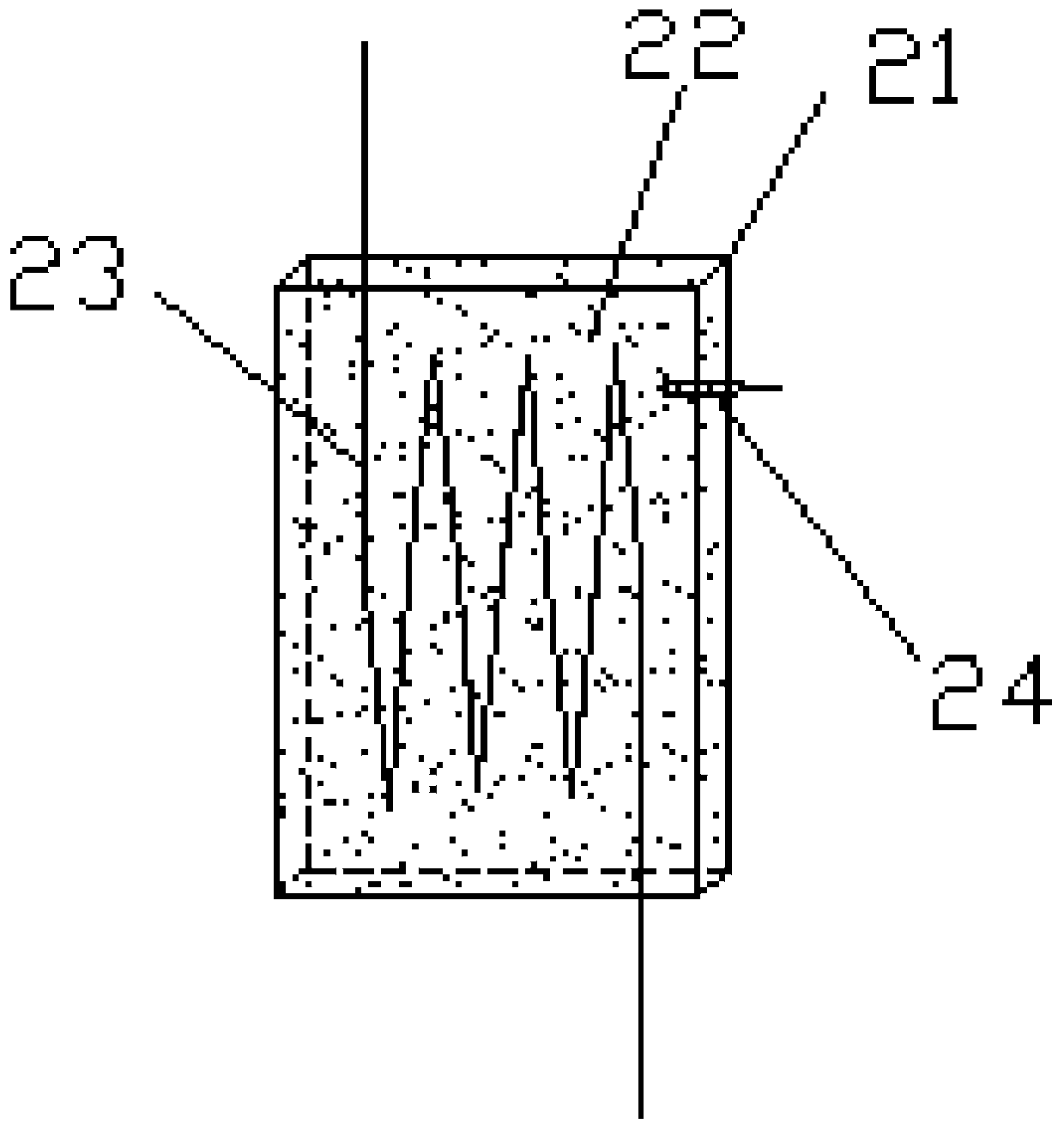

[0020] Such as figure 2 The heat storage plate 2 is made of aluminum with good thermal conductivity and includes a heat storage plate shell 21. The heat storage plate shell 21 is filled with paraffin wax 22. Aluminum powder can be added to the paraffin wax 22 at a mass percentage of 3 to 5%. Sealing the paraffin wax 22 in the heat storage plate shell 21 can effectively prevent the paraffin wax 22 from leaking during use, thereby prolonging the service life of the heat storage plate 2. A temperature sensor 24 and an electric heating wire 23 are also installed on the heat storage plate shell 21. The temperature sensor 24 and the electric heating wire 23 extend from the heat storage plate shell 21 into the paraffin wax 22, heating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com