Fastener stringer, slide fastener for luggage case, and luggage case

A technology of zipper teeth and zippers, applied in the field of zipper teeth chains, which can solve the problems of suture wear, effort, and increased manufacturing costs, and achieve the effect of preventing suture wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

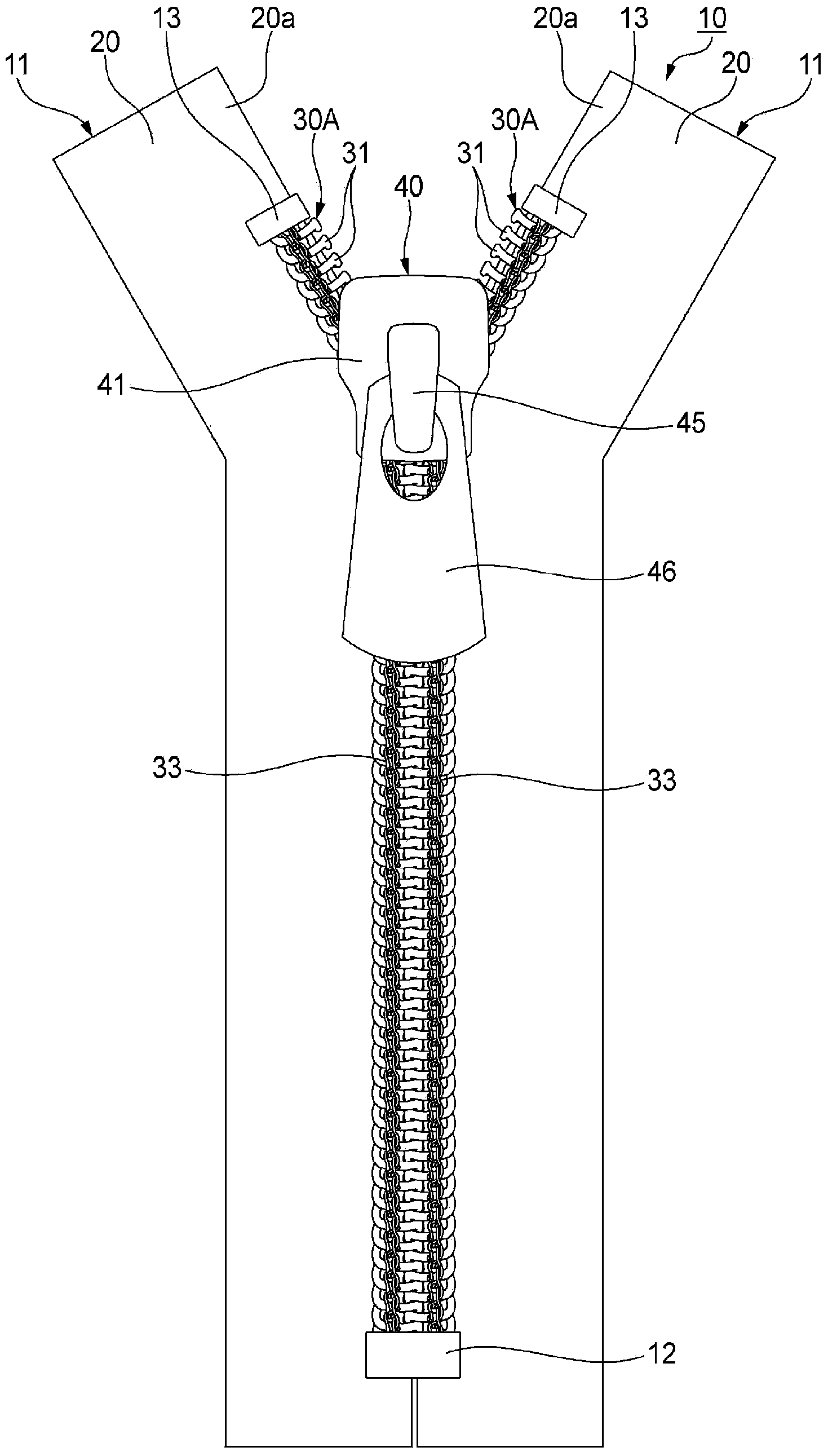

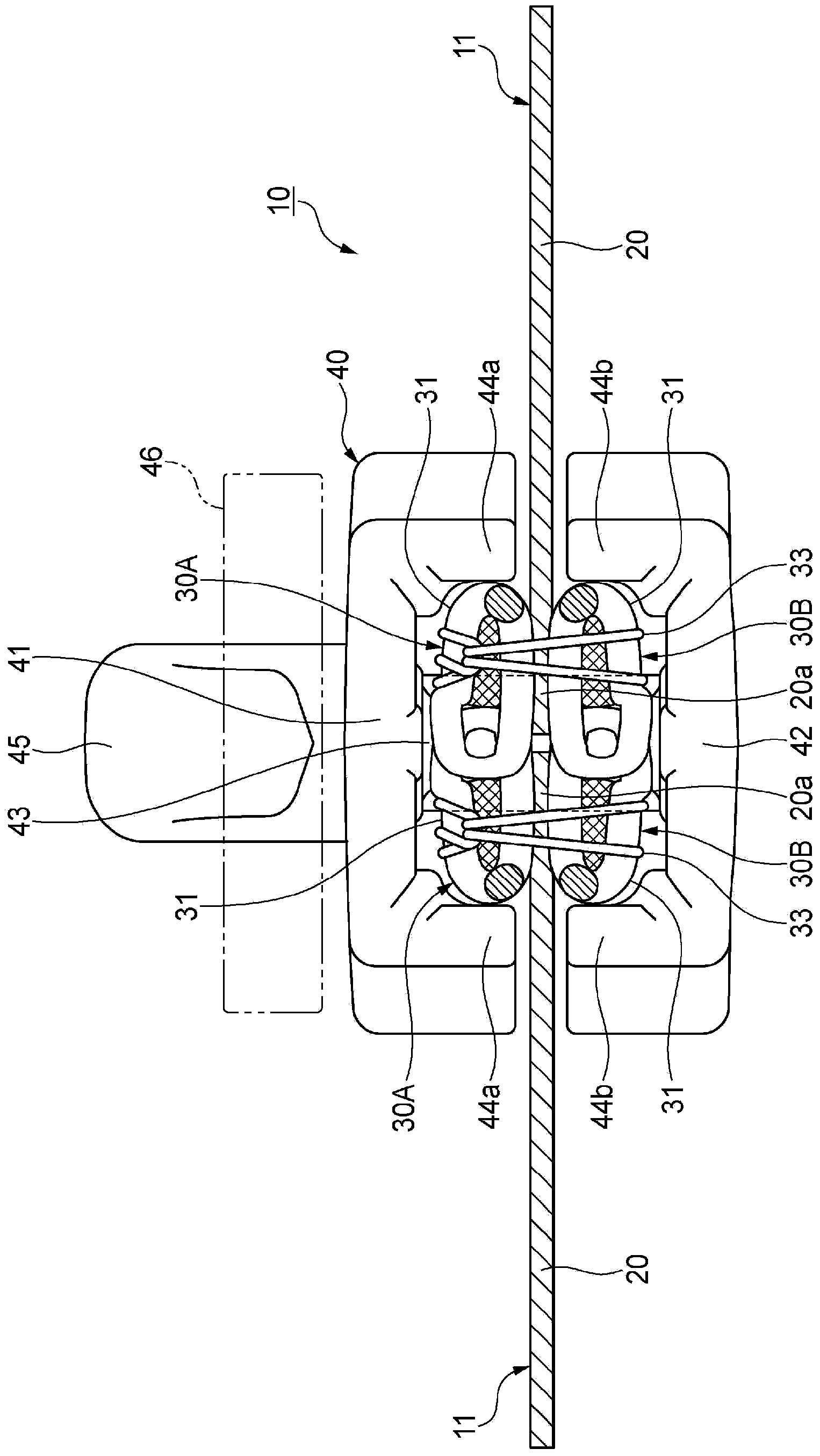

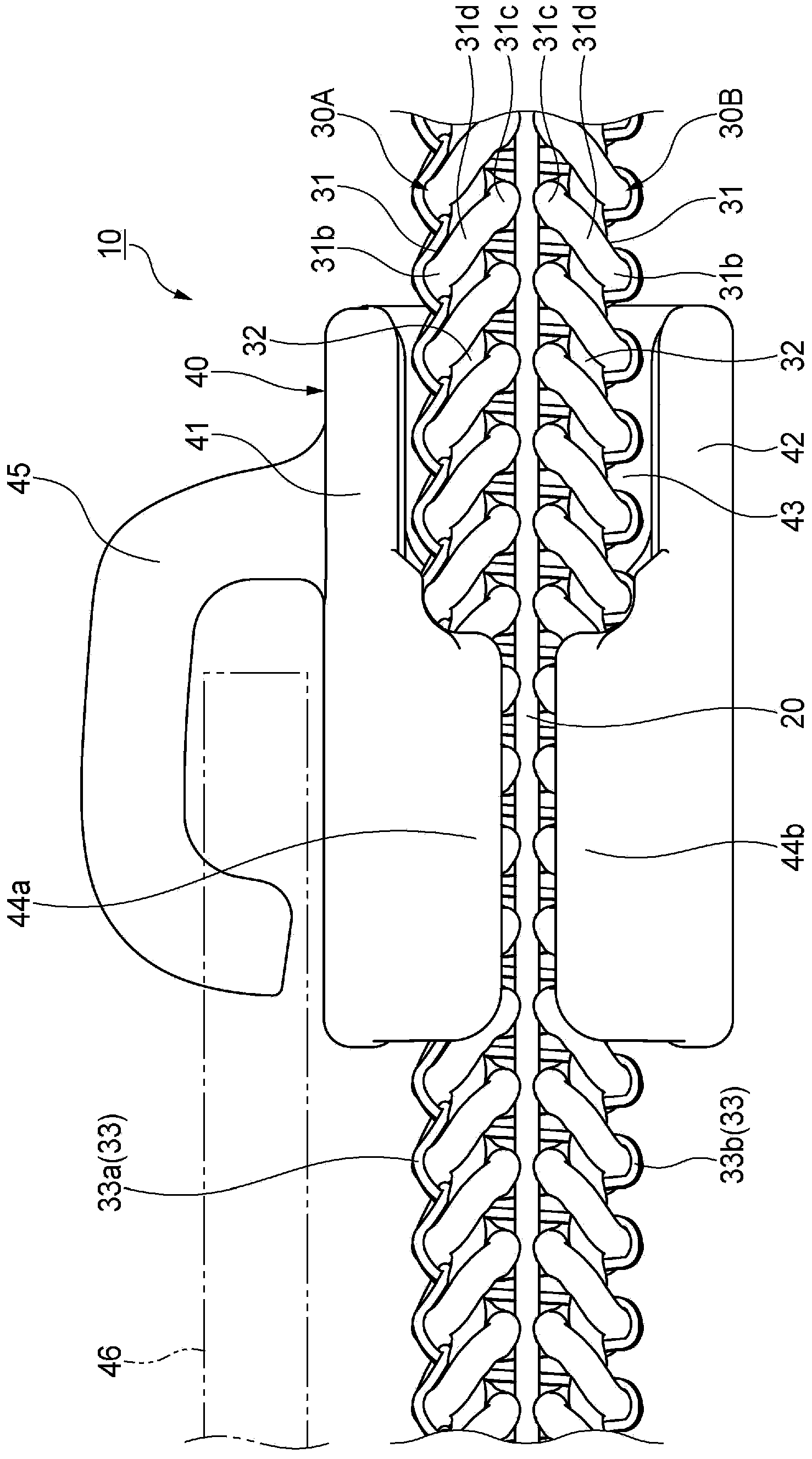

[0047]Next, one Embodiment of the slide fastener chain, the slide fastener for bags, and the bag which concerns on this invention is demonstrated in detail based on drawing. In addition, in the following description, for the chain, the front side is set to figure 1 The near front side of the paper, the back side is set to figure 1 The far side of the paper, the upper side is set to figure 1 The upper side of the paper, the lower side is set to figure 1 The lower side of the paper, the left side is set to figure 1 The left side of the paper, the right side is set to figure 1 right side of the paper. Additionally, for sliders, the upper side is set to figure 1 The near front side of the paper, the lower side is set to figure 1 The far side of the paper, the front side is set to figure 1 The upper side of the paper, the back side is set to figure 1 The lower side of the paper, the left side is set to figure 1 The left side of the paper, the right side is set t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap