Capacitive pressure sensor with improved electrode structure

An electrode structure, capacitive technology, applied in the direction of measuring fluid pressure through electromagnetic elements, measuring fluid pressure, instruments, etc., can solve problems such as unpredictability and compensation, mechanical lag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Exemplary embodiments are now discussed. Other embodiments may additionally or alternatively be used. Obvious or non-essential details may be omitted to save space or for more effective presentation. Rather, some embodiments may be practiced without all of the details disclosed.

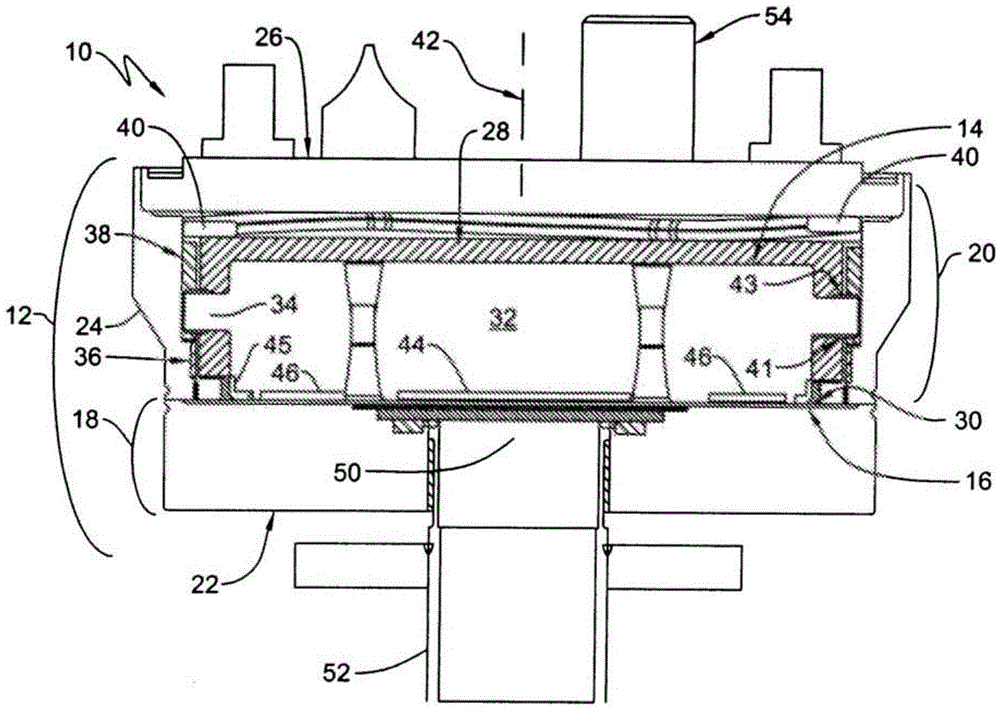

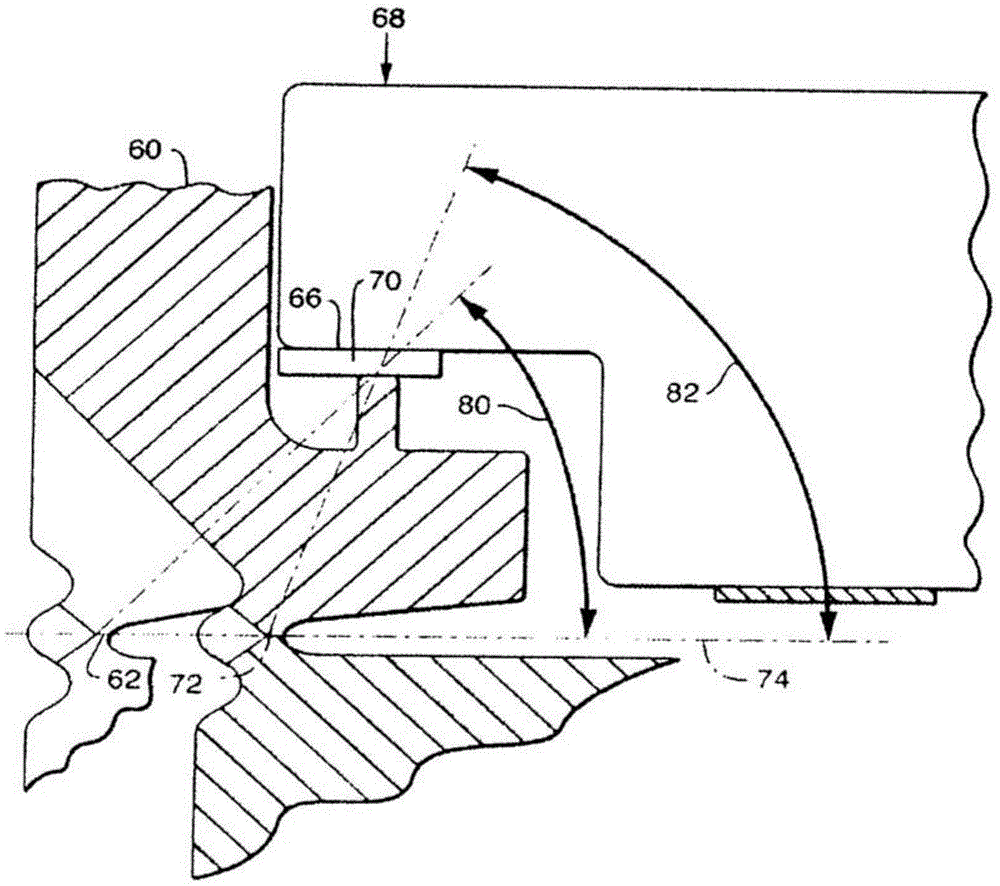

[0042] According to one aspect of the invention, a series of slots are introduced into the integrally formed compliant ring, thereby relieving hoop stresses, creating a series of independent flexures which allow a reduction in the radial spring constant at the electrode disc support, while No further reduction in (radial) thickness is required. This effectively reduces the radial spring constant and the maximum possible radial shear load between the electrode disc and sensor housing, while still maintaining the practical usable thickness of the element.

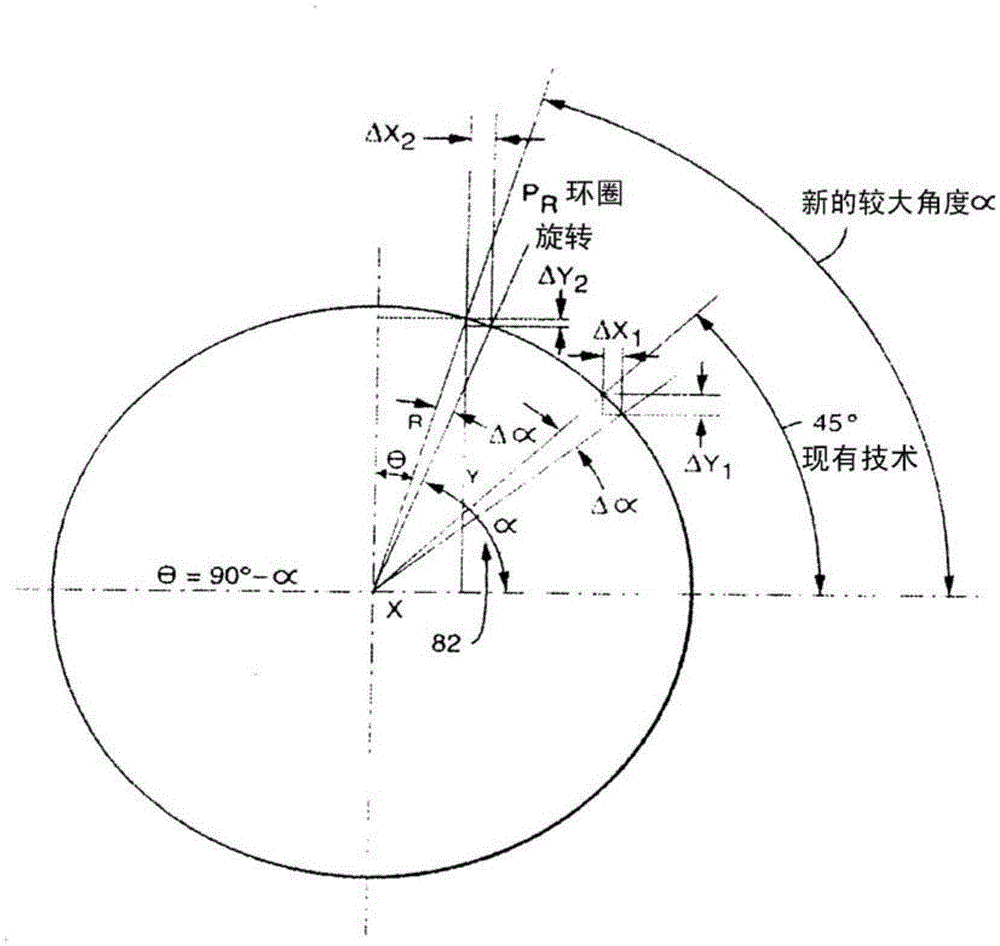

[0043] To accurately measure the lowest pressures, improved control over critical sensor geometries is required. Reduction of the larges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com